Vibrating Feeder

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum, quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, etc.

What is Vibrating Feeder?

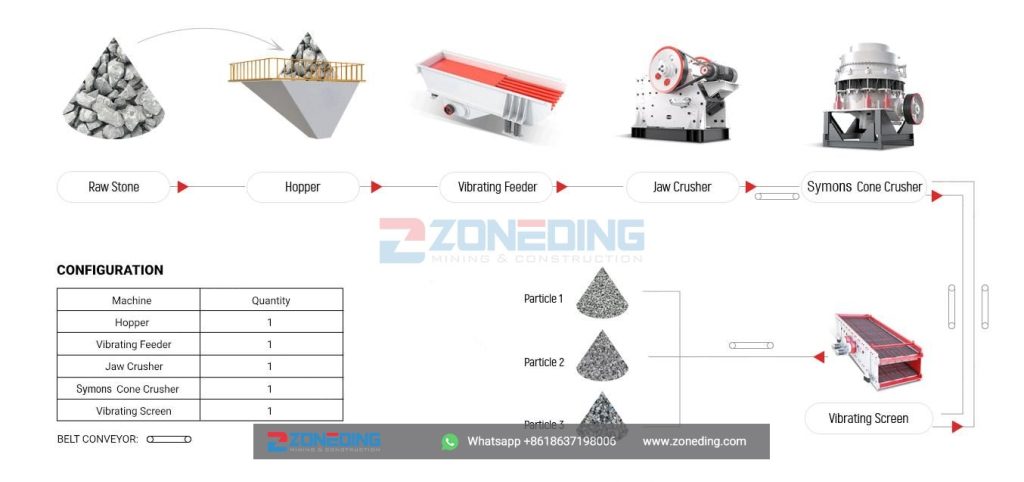

The vibrating feeder can evenly feed materials for the crushing equipment in the sand production line, and screen materials roughly. It can also serve materials for belt conveyors, bucket elevator, screening equipment, crushing equipment and grinding machines.

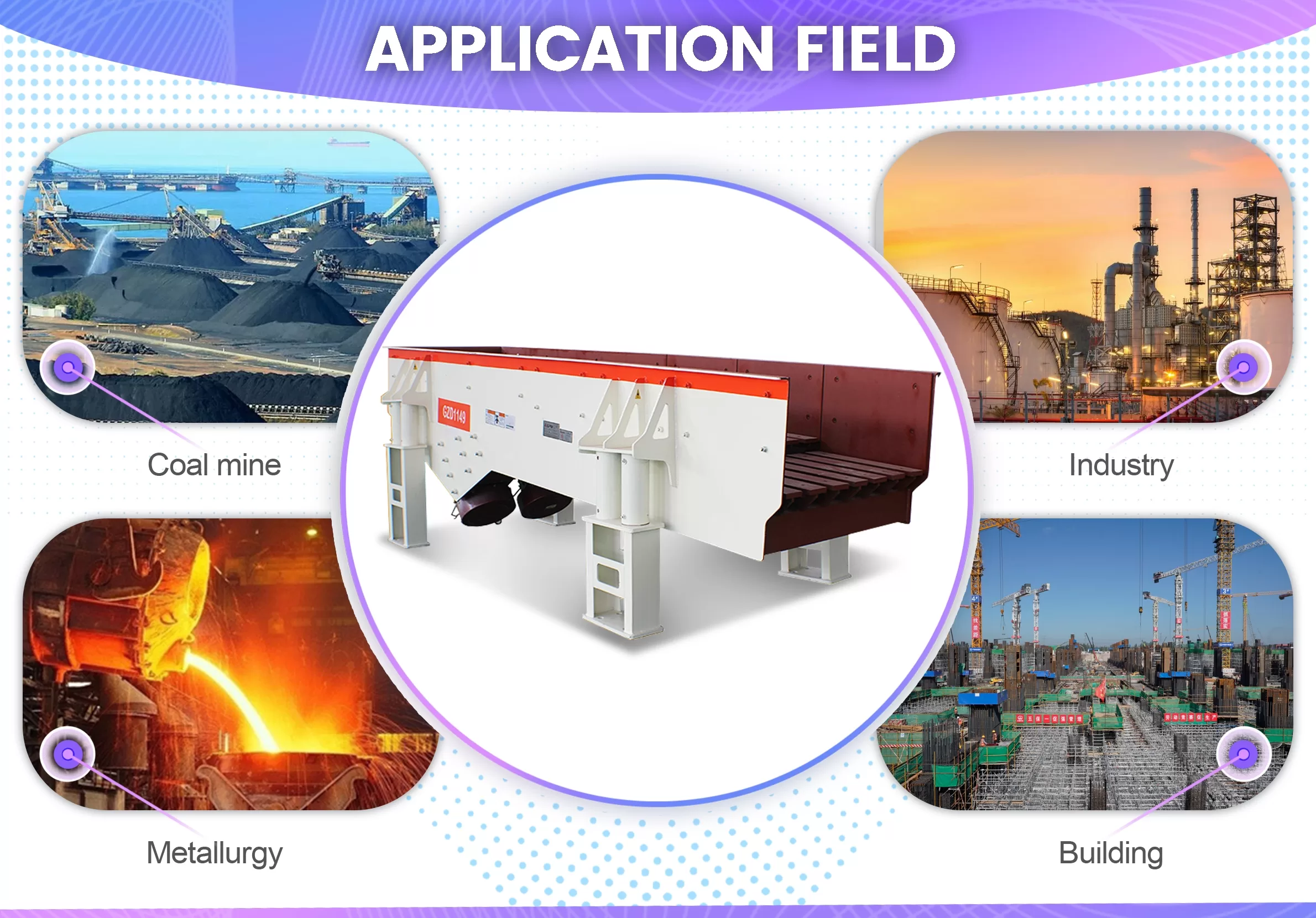

Applications of ZDM Vibrating Feeder

Mining vibrating feeder has a very wide range of use, mainly used in mining, metallurgy, coal, building materials, chemical industry, electric power and other industries. The following is the specific scope of use:

In the mining industry, the mining vibrating feeder is used to convey raw ore from the excavation site to the crusher or screening equipment. Its efficient vibration mechanism can effectively separate and convey ores of various particle sizes and improve production efficiency.

In the metallurgical industry, the equipment is used to feed lumpy, granular and powdery materials uniformly, continuously or quantitatively from storage silos or other storage equipment to the receiving equipment, in order to meet the needs of automatic batching, quantitative packaging and automatic control.

In the coal industry, mining vibrating feeder can be used to evenly transport coal from the silo to the crusher or screening equipment to improve the efficiency of coal processing.

In addition, mining vibrating feeder is also widely used in building materials, chemical industry, electric power and other industries for conveying and processing various materials.

How Vibratory Feeder Work

The working principle of the vibrating feeder is mainly to use the eccentric block in the vibrator to rotate to produce centrifugal force, so that the movable parts of the screen compartment and vibrator make a forced and continuous circular or nearly circular motion. This movement is transmitted to the conveying trough connected to the vibrating motor, so that the material is subjected to vibration force in the trough, thus generating sliding and dislodging, and realizing the uniform and continuous conveying of materials.

Specifically, when the vibrating feeder works, the motor drives the main shaft through the triangle belt, and then drives the follower shaft to rotate through the meshing of gears. The rotation of the main shaft and the driven shaft causes the eccentric block to generate centrifugal force that varies periodically, and this centrifugal force acts on the screen compartments and the vibrator, making them do continuous circular or nearly circular vibration. This vibration is transmitted to the conveying trough, so that the material in the trough is subject to the action of the vibration force and jumping and sliding, along the direction of the conveying trough, and ultimately realize the uniformity of the material, continuous or quantitative conveying.

In addition, the mining vibrating feeder can also be adjusted by adjusting the phase and weight of the eccentric block to change the size and direction of the excitation force, so as to adapt to the changes in different materials and process requirements. This kind of adjustment is flexible and convenient, and can realize precise feeding control.

Advantages of Vibrating Feeder Machine

Simple structure, easy maintenance: the overall structure of the equipment is compact, covers an area of small, easy to install, debugging, maintenance.

Uniform and continuous feeding: by adjusting the excitation force and vibration frequency, it can realize the uniform and continuous conveying of materials and avoid the phenomenon of material blockage and accumulation.

Strong adaptability: for ores or materials with different granularity and hardness, mining vibrating feeder can be adapted and maintain good feeding effect.

Energy saving and environmental protection: the equipment in the operation process of low noise, low energy consumption, in line with the requirements of environmental protection.

High efficiency and durability: mining vibrating feeder is made of wear-resistant materials, long service life, stable and reliable operation, which can reduce the production cost.

General Specification

Vibrating Feeder

| Model | Max.Feeding Size(mm) | Processing Capacity(t/h) | MotorPower(kw) | Obliquityof materialtrough(°) | Troughsize(mm) | Dimensions(mm) |

| GZD-650×2300 | 300 | 80-100 | 1.2×2 | 10-20 | 650×2300 | 2300×1360×780 |

| GZD-750×2500 | 350 | 100-130 | 1.5×2 | 10-20 | 750×2500 | 2500×1460×780 |

| GZD-850×3000 | 400 | 120-150 | 3×2 | 10-20 | 850×3000 | 3110×1800×1600 |

| GZD-1000×3600 | 500 | 150-200 | 3.7×2 | 10-20 | 1000×3600 | 3850×1950×1630 |

| GZD-1100×3600 | 580 | 240-300 | 3.7×2 | 10-20 | 1100×3600 | 3600×2050×1660 |

| GZD-1300×3600 | 650 | 450-600 | 7.5×2 | 10-20 | 1300×3600 | 3900×2350×1750 |

| GZD-1500×3600 | 1050 | 450-1000 | 7.5×2 | 10-20 | 1500×3600 | 3900×2000×1750 |

| GZD-2000×3600 | 1200 | 550-1000 | 10×2 | 10-20 | 2000×3600 | 3600×2000×1750 |

| GZD-2500×5000 | 1500 | 650-1500 | 18×2 | 10-20 | 2500×5000 | 5000×2500×1800 |

| ZSW-380×95 | 500 | 100-180 | 11 | 0-10 | 3800×960 | 3920×1640×1320 |

| ZSW-490×110 | 630 | 150-400 | 15 | 0-10 | 4900×1100 | 4980×1830×1320 |

| ZSW-490×130 | 750 | 400-700 | 22 | 0-10 | 4900×1300 | 4980×2580×2083 |

| ZSW-600×130 | 750 | 400-700 | 22 | 0-10 | 6000×1300 | 6082×2580×2083 |

| ZSW-600×150 | 800 | 500-900 | 30 | 0-10 | 6000×1300 | 6086×2662×1912 |

| ZSW-600×180 | 900 | 700-1300 | 45 | 0-10 | 6000×1500 | 6310×3262×2230 |

| ZSW-600×200 | 1200 | 800-1500 | 55 | 0-10 | 6000×2000 | 6310×3462×2230 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine…

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine