Three-drum Dryer

A three-drum dryer, also known as a three-cylinder dryer, is an improved version based on a single drum dryer with advanced German technology, mainly composed of three concentric circles, and is used to dry granular materials with certain moisture and particle size.

- Capacity: 5-100 t/h

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source: biomass, natural gas, diesel, coal, etc.

- Application: Suitable for drying the sand, silica sand, fly ash, mineral slag and other material.

What is Three-Drum Dryer?

three-drum dryer is also known as a three-cylinder dryer or a three-drum dryer. It is an improved version based on a single drum dryer and is supported by modern and advanced German technology. The three-cylinder dryer is mainly composed of three concentric circles of different diameters. Compared with the traditional drum dryer, the three-drum dryer has better sealing technology and is equipped with a more scientific machine. This dryer is usually used to dry granular materials with a certain moisture and a certain particle size range. For example, a three-drum dryer can be used to dry clinker, sand, molding sand, slag, cinder, fine-grained clay, high-temperature resistant and dusty particles.

Three-Drum Dryer

Applications of Three-Drum Dryer

Three-drum dryer is widely used in building materials industry, metallurgical industry, mineral processing industry, chemical industry, cement and other industries. It is suitable for the drying of various granules and powders in the above industries. After drying, the humidity of the material can reach below 1%. Some application examples of three-drum dryers:

- Yellow sand in the dry mortar industry and full-size artificial sand in the foundry industry

- Sandblasted surface slag, limestone and quartz/silica sand in the building materials and cement industries

- Chemical industry residues, concentrates and tailings

- Coal slime, raw coal, flotation coal concentrate and blended coal in the coal industry

- Other wet granular materials such as metal powder, fly ash, river sand, gypsum, etc.

Three-Drum Dryer Application

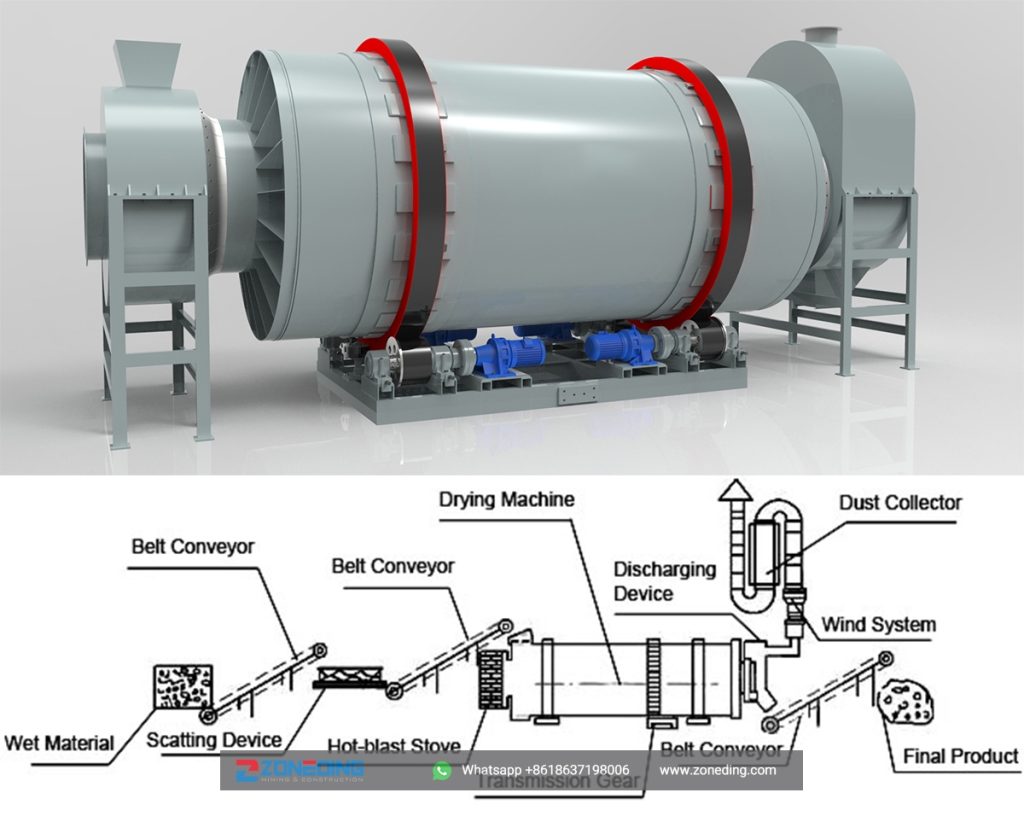

How Three-Cylinder Dryer Works?

Radiation, convection, and heat conduction are mainly used in the drying process. The dryer is set at an angle to take advantage of gravity. When the hot air in the oven reaches the set temperature, the dryer works according to the order of the PC system. The wet pellets are then evenly fed into the inner layer by the feeder and carried away by the gale. The wet material is spirally conveyed through the fixed shovel plate. Next, the material moves to the other end of the oven and into the middle layer. This time, the wet powder inside leaned against the blower and moved forward, taking two steps back. In the middle layer, the heat from the inner and middle layers is fully utilized, which increases the drying efficiency to the optimum. Finally, the dried material reaches the other end of the middle layer and enters the outer layer in a rectangular and multi-loop pattern. Drying to solidify the moisture of the granular material is blown out of the dryer. The rest move more slowly due to their weight and dry again in the outer layer to the desired humidity. In this way, the drying process is realized.

Working Principle of Three-Cylinder Dryer

The structural advantages of the zoned three-drum rotary dryer

Compared with traditional dryers, three-drum dryers have obvious advantages;

- The discharge temperature is less than 50 degrees, and it can directly enter the base without cooling. In addition, the low emission temperature will extend the life of the dust collection system.

- There is no air leakage, which completely solves the difficulty of sealing. It can be installed in 2 hours.

- The thermal efficiency is up to 80% (compared to 32% for conventional single-cylinder dryers), an increase of 48%.

- Compared to a single-drum dryer, the occupied area is reduced by about 50%, so the land investment is reduced by about 50%.

- The coal consumption is 1/3 of that of a single-cylinder dryer, and the energy saving is 40%. The standard coal consumption per ton of material processed is less than 9 kg. Small dryers save 50-100 million yuan per year, and large dryers save 100 million-200 million yuan per year.

How to Choose a Suitable Dryer?

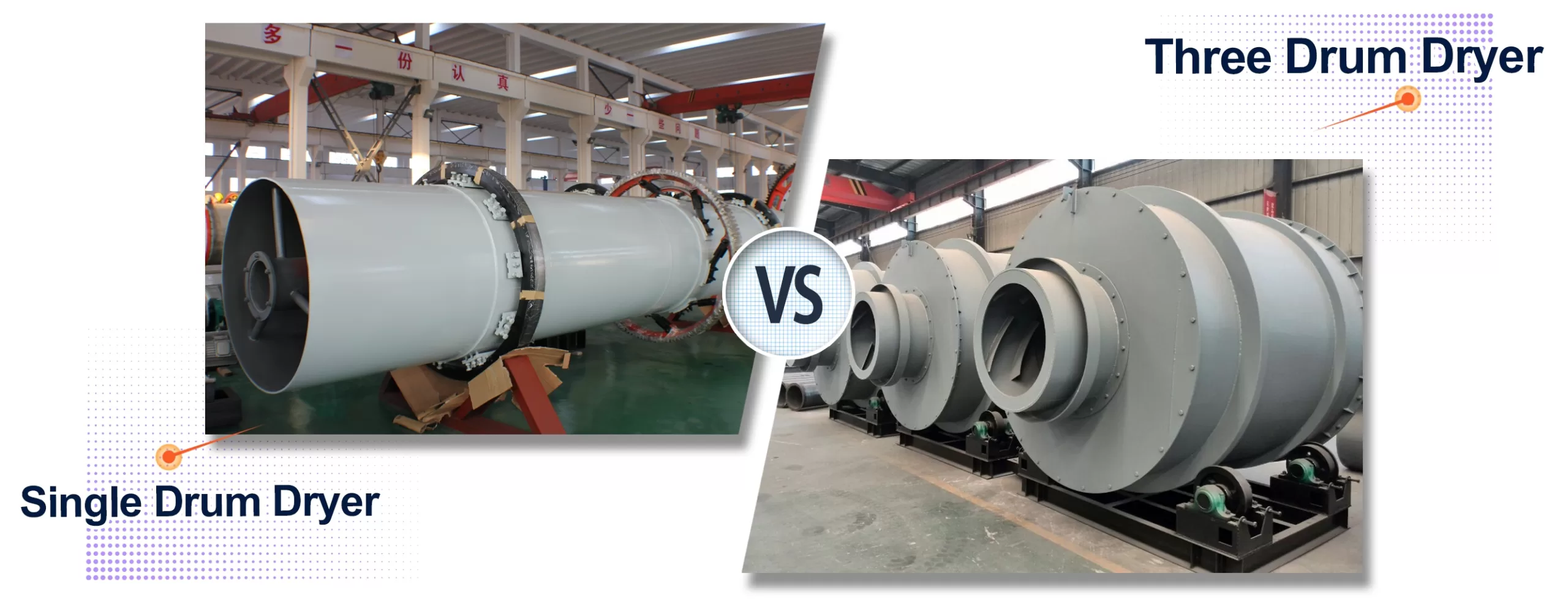

There are types of drum dryers, such as single drum dryers, double drum dryers, triple drum dryers, and air dryers. It’s always confusing for customers to make decisions. Take a single-drum dryer and a three-drum dryer as an example to clarify how to choose the right dryer.

| Single Drum Dryer | Three Drum Dryer | |

| Diameter of Outer Cylinder(m) | 1.2-3.6 | 2.5-3.6 |

| Length(m) | 8.0-28.0 | 7.0-8.0 |

| Volume(m3) | 9.0-285.0 | 16.63-81.38 |

| Capacity(T/H) | 1.9-76.0 | Yellow Sand: 25-70Slag: 20-65 |

Three-Drum Dryer VS Single-Drum Dryer

General Specification

Sand dryer

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand:25-30 Slag: 20-25 | Yellow sand:30-35 Slag:25-30 | Yellow sand:35-40 Slag:30-35 | Yellow sand:45-50 Slag:35-40 | Yellow sand:65-70 Slag:60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine