Sludge Dryer

Zoneding Company conducted technical research on sludge treatment, created a new generation of sludge rotary drum drying system that can reduce product moisture to less than 25%, with mature technology and easy operation and maintenance.

- Moisture Reduction: 40-75%

- Capacity: 1.9-76.0 t/h

- Heat Source: biomass, natural gas, diesel, coal, etc.

- Application: Widely used for drying sludge, slurry, ETP sludge, Slime, Paper pulp, Pomace Sludge, etc.

Over 200 Exported Countries: Russia, South Africa, Mexico, Egypt, Australia, South Korea, India, Malaysia, Kenya, Holland, et

What is Sludge Dryer?

Sludge drying is a process to dewater and recycle high-moisture sludge as resource. there are mainly two ways to dry sludge, natural drying and mechanical drying. The latter is more efficient. The removal of water reduces the sludge quality and volume, which is to make it convenient to be store and transport the sludge. With mature and advanced international technology from Europe, etc., Zoneding solution on sludge drying process is based on the properties, like high water content, high organics content, and low specific gravity, etc.

According to different customers’ needs, Zoneding offers sludge drying machine with different heat sources.

✔ Solid fuel like coal

✔ Gaseous fuel like gas, steam, etc.

✔ Liquid fuel like oil, etc.

Applications of Sludge Dryer Machine

Produced from sewage disposal, sludge actually can be transformed by special designed sludge dryer equipment into a kind of green fuel and resource. Sludge is an extremely complex heterogeneous material composed of organic fragments, bacteria, inorganic particles, colloids, etc. Sludge has the characteristics of high moisture, high organic matter content, fine particle and small specific gravity.

Sludge dryer plays a key role in dehydrating and drying wet sludge to a certain moisture. Dried sludge can be used in agriculture to improve the soil, in building materials production to be the raw material of cement and in brick making. Besides, sludge dryer can be used to make biochemical fiberboard.

Applications of Sludge Dryer

Zoneding Sludge Drying Machine Structural Advantages and Benefits

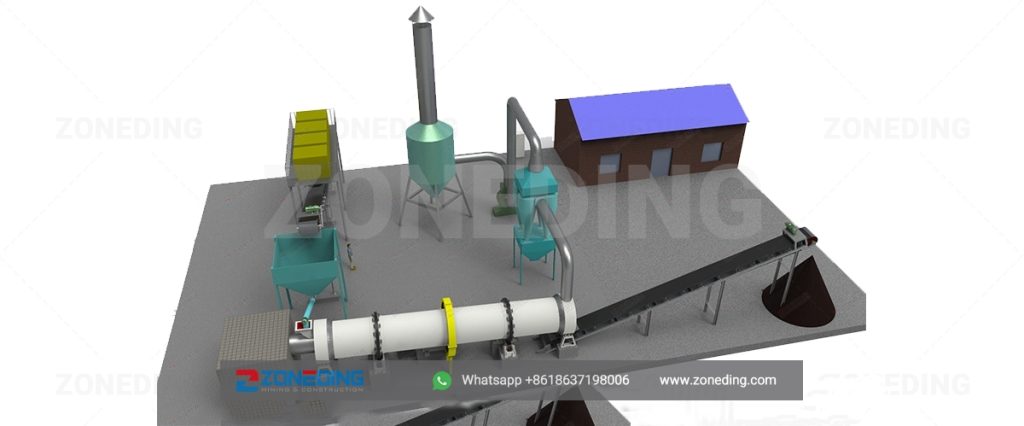

It is mainly composed of barrel, supporting device, driving device and sealing device, etc. The working areas include discharging area, lifting board area, cleaning area and feeding area.

- Advanced structure, wide applications and strong adaptability. New grouped self-cleaning device inside the inner wall makes it easier to dry various sludge and other materials of high viscosity.

- Wearable parts and durability. Our sludge dryer machine uses high-quality steel in the dryer production, which is of extreme hardness and toughness; the under rollers are designed reasonably and ways to lubricate are available.

- Effective drying and high thermal efficiency. Well-equipped transmission, exhaust and feeding and discharging radiator help the dryer machine perform excellently. Scorching air blows at high speed, so the material is fully dispersed.

- Stable quality of finished products. Dried granular or powder sludge volume is lessened 4-5 times but the quality stays. It is a great improvement of sludge nature

- Other benefits: Smooth running, elegant appearance, low noise, etc.

What a Sludge Dryer Brings to You?

An efficient use of sludge brings environmental protection as well as over-expected economic benefits.

Ⅰ. Reducing Weight and Volume

Sludge dryer reduces the sludge volume and weight by evaporation of water in it, making it easier to store and transport.

Ⅱ. Stabilize Sludge

Drying can stabilize the sludge, thus reducing the putrid smell and improving the disinfection effect.

Ⅲ. Simplify the Next Process

Either in following sludge disposal or in direct recycle process, sludge drying equipment plays an essential part of boosting the calorific value of sludge, which makes sludge easier to be used as fuel.

Classification and Differences of Sludge Dryers

There are two commonly used types of sludge dryer machine, single-cylinder rotary sludge dryer and high-viscosity sludge drying equipment.

The first is newly developed from ordinary rotary dryer with cleaning device, breaking device and others inside. For drying material with a certain viscosity and smaller particle size, single-cylinder rotary sludge dryer is the better choice.

The latter usually uses hot-air spiral-blade drying technology with double or three shafts alternative according to the viscosity of the sludge. This drying machine can dry sludge with humidity below 85% to 12% or below just one time. And this drying process takes less time like 2-10 mins.

General Specification

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Customer Site

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine