Search the whole station Crushing Equipment

The slag drum dryer is an industrial drying equipment that reduces the moisture content of slag, making it easier to handle or reuse. This process is crucial for waste management and potential further applications of slag.

Over 200 Exported Countries: England, Zimbabwe, Mongolia, Ukraine, Indonesia, Mexico, South Africa, Albania, Tonga, Canada, Italy, Pakistan, Philippine, etc.

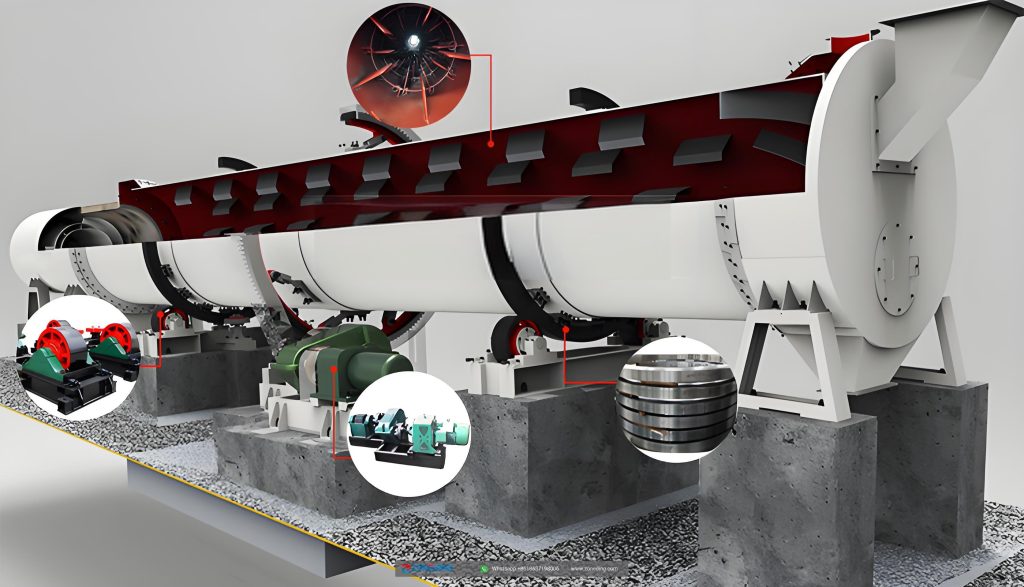

To recycle slag produced in ore dressing or smelting industry, Zoneding Machinery develops new advanced dryer for slag drying. Zoneding slag dryer machine is commonly used in building materials, chemical industry, cement, etc. Mainly composed of rotary cylinder, lifting blades, self-cleaning device and other equipped devices, slag dryer, or slag drying machine operates stably as well as is of mature technology, high production capacity and efficiency.

√ High temperature fluidized furnace

√ Pulverized coal duster furnace

√ Artificial coal furnace.

Slag is a non-metallic byproduct created during the smelting of metals. When molten metal is separated from its ore, the impurities float to the top and are skimmed off. This molten material is then cooled to form a hard, glassy, or crystalline rock-like substance. The two most common types are:

Wet slag has very limited use and is expensive to transport. Drying is the essential first step to making it a marketable commodity. Drying slag:

Dried and processed slag is a valuable raw material, particularly in construction. Its applications are a key reason to invest in a slag drying process.

A complete slag drying process is a robust, multi-stage system designed for extreme duty:

A slag dryer is a highly specialized type of industrial rotary dryer built to withstand the extreme abrasion and high temperatures required for this application. It is not an ordinary dryer. It is a heavy-duty machine where every component, from the steel shell to the drive system, has been reinforced and designed for a high-wear environment.

While most are rotary dryers, the design differs based on the slag type. You must never confuse a steel slag dryer with a blast furnace slag dryer.

Thanks to its own cleaning device and material lifting plate, slag dryer is extensively applied to dewater wet materials with large specific gravity.

Drying Requirement: Blast furnace slag is typically generated during the smelting process by water quenching and often carries a high moisture content.

Application: After drying, blast furnace slag can be used as a concrete additive, road base material, cement product, etc. Due to its higher silicon content, it can also be utilized in glass manufacturing.

Drying Requirement: Furnace slag is typically generated during the metal smelting process, and its moisture content depends on the smelting process and cooling method. Certain types of furnace slag may require drying to reduce moisture content.

Application: After drying, furnace slag can be used in road construction, soil improvement, cement production, etc. It can also serve as railway track materials.

Drying Requirement: Coal gangue is a byproduct generated during coal mining, with high moisture content, often requiring drying to reduce moisture levels.

Application: After drying, coal gangue can be used to manufacture bricks, tiles, coal gangue bricks, and other building materials. It can also be utilized in power generation, cement manufacturing, and other industrial applications.

Drying Requirement: Bauxite residue is typically generated during the extraction of aluminum, with relatively high moisture content, requiring drying treatment.

Application: After drying, bauxite residue can be used for soil improvement, mine reclamation, cement production, etc. It can also be utilized in the production of ceramics, glass, and other products.

Our slag dryers are designed to process various industrial byproducts, including:

Co-current heating mainly works in slag drying process. Wet slag is transmitted into the cylinder by the feeding box and feeding conveyor. Then it is pushed back to the other end of the cylinder of the drum by spiral blades inside. The dryer is set at a certain angle. On one side, the wet slag flows down to the exit under the effect of gravity and rolling. On the other, it is brought up to the top end of the cylinder by the blades and falls into a screen to get in full touch with the scorching wind. Thanks to this repeated proceeding, wet slag is dried step by step.

Working Principle of Slag Dryer

After the wet slag enters the drying drum, it first enters the loading area, where the wet slag quickly contacts the high-temperature hot air and begins to evaporate its water. At the same time, under the push of the large inclination of the loading plate, the slag is not easy to adhere and smoothly transitions to the next working area.

Then the wet material enters the lifting and cleaning area, where the wet material is lifted by the lifting plate to form a curtain shape. Since the wet slag is easy to adhere to the inner wall of the drum when it falls, the equipment is designed with a cleaning device to effectively remove the adhered slag. At the same time, the cleaning device can also break up the slag blocks, increase the heat exchange area, and increase the drying speed.

Next is the inclined loading area. In this area, the wet slag has reached a low-moisture loose state and no longer shows cohesiveness. After sufficient heat exchange, the slag reaches the required moisture content and is ready to enter the unloading area.

The last is the unloading area. Here, the drum no longer has a lifting plate. The wet slag rolls and slides to the unloading port in this area to complete the entire slag drying process.

Your dryer is not a dryer; it is a grinding mill that you feed with steel byproduct. The structure must reflect this reality.

Slag Dryer Machine Structure

Slag dryer is also a kind of rotary dryer, which is mainly composed of a rotating cylinder, induced draft fan, high-speed scattering equipment, lifting plates, self-cleaning device, transmission device, conveyor, hot air equipment, reducer, supporting device, sealing device and other components.

Structure of Slag Dryer

The key to extend the service life of the slag dryer is to do often maintenance and check. Based on experience, Zoneding engineers give some tips for reference.

1, Bearings take all the load of the machine. Therefore, satisfactory lubrication is much concerned with the service life. Lubricant oil infused shall be clean and the container shall be sealed well;

2, Frequently check the newly installed tyre, which is easily loosed;

3, Pay more attention to the easily-worn parts and be ready to replace those need to;

4, Pay much attention to the oil temperature of the bearing parts. Put an end to the dryer immediately, if it goes up higher. Find the cause and figure it out.

5, An impacting sound from the rotating wheels shall call your attention to stop this drying machine. Immediate check and solutions are needed.

The slag is fed into the rotating drum and is immediately shattered by the chains or hammers in the inlet zone. As it moves down the drum, the cast lifters continuously cascade it through a stream of hot gas from a furnace. For GGBS production, this process is critically controlled.

The goal is not to get to 0% moisture. This is the counter-intuitive secret of GGBS production. The cement-like properties of granular blast furnace slag come from its glassy structure. If you overheat the slag (material temps over 150°C), you change its crystal structure and permanently kill its value. A perfectly dried GGBS should retain about 0.5% residual moisture. Going to zero is a waste of fuel and actively destroys your product.

At ZONEDING, we engineer our slag dryers for decades of profitable service in the harshest conditions.

The cost of a slag dryer machine can range widely from $200,000 to over $3,000,000. The final price is determined by:

A cheap slag dryer is one that lacks the necessary abrasion-resistant materials. It will fail quickly, and the cost of downtime and replacement will far exceed any initial savings.

Choosing the right dryer begins long before you look at equipment.

Maintenance is a proactive battle against wear.

What are the main applications for a slag dryer?

The two main applications are 1) Producing tough, durable aggregate for roads and concrete blocks from steel slag. 2) Producing ground granulated blast-furnace slag (GGBFS), a valuable substitute for cement, from blast furnace slag.

How can I increase the output of my slag dryer?

First, ensure your feed material is consistent and that the inlet crushing zone is effectively breaking up clumps. Second, optimize your burner for a stable heat output. Finally, ensure your dust collection system is not a bottleneck and can handle the required airflow. Often, output is limited by what the downstream systems can handle.

What are the most common problems with a slag dryer?

The most common problem is rapid and catastrophic wear of the internal shell and lifters due to slag’s extreme abrasiveness. The second is plugging at the inlet if the feed is too wet and sticky. The third is corrosion at the cold feed end due to acid gas condensation.

What is the impact of climate on a slag dryer?

In cold climates, your wet slag pile may freeze, making it extremely difficult to feed. This requires a more robust feed system. In very humid climates, the air contains more moisture, which can slightly increase the slag dryer fuel consumption as the dryer has to heat this extra water. However, the moisture in the slag itself is a far bigger factor.

Buy industrial gypsum dryer for sale. Efficiently remove moisture from gypsum rock & powder. Improve product quality & processing speed.

Rotary cooler for sale. Efficiently cool hot materials discharged from kilns & dryers. Improve process speed & material quality.

Buy industrial rotary kiln for sale. Achieve efficient high-temperature thermal processing, calcining, roasting & drying of minerals, ore, cement & more.

Find high-efficiency sludge dryers for sale. Reduce sludge volume, cut disposal costs, and improve handling. Ideal for municipal & industrial applications.

Discover high-performance aggregate and sand dryers for sale. We offer triple-pass and rotary drum models for efficient moisture removal. Get a quote today!

Looking for a high-efficiency triple-drum rotary dryer? Saves energy, space, and cost; suitable for drying sand, coal, and biomass. Rugged and reliable.

Purchase an industrial bentonite dryer suitable for various applications such as drilling mud, cat litter, and foundry work. Achieve optimal moisture content and uniform drying.

Specialized Coal Dryer machines for power generation, coking, and briquetting. Improve fuel efficiency, reduce transport costs & enhance combustion.

Professional slurry dryer manufacturer with CE/ISO certification. Customizable 5-50t/h capacity, 35% energy saving. Get instant technical specs download.

This mineral powder dryer is specifically designed for use with mineral concentrates, iron ore powder, and metallurgical slag. It ensures uniform drying, improving product quality and recovery rates.

loading…

已经是到最后一篇内容了!