Search the whole station Crushing Equipment

Our Shaking Table are available in different styles and numerous model sizes in each style to adapt to various mineral separation requirements.

A shaking table, sometimes called a gold shaker table or gold recovery table, is a vital mineral processing device. This machine uses gravity and a vibrating surface to separate materials based on their specific gravity. This basic principle makes it invaluable in many gold mining shaker table operations.

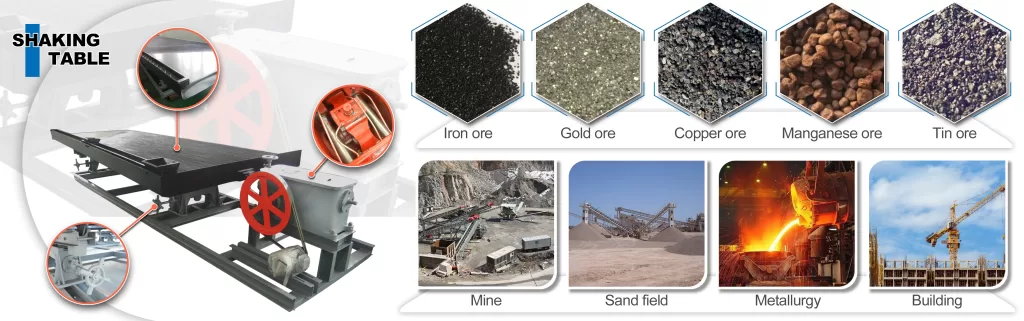

Shaking table is a kind of gravity beneficiation equipment, which is mainly used for separating gold, silver, lead-zinc, tantalum-zinc, tin and other rare metal and precious metal ores.

Core aspects of a shaking table for separating gold in table:

Why pick a gold mining shaker table?

The advantages of using a gold mining shaker table over other methods are numerous: high separation efficiency (especially with fine particles), low operational costs due to the simple design, and effectiveness in gold recovery. Gold shaker tables prove useful in the separation of gold and other precious metals.

Here’s why a gold mining shaker table is a good investment:

A small gold shaker table is typically used for processing smaller batches of material, pilot testing, or in laboratory shaking table settings. A small gold shaker table offers a cost-effective solution for those entering the field or for small-scale operations.

Applications of a small gold shaker table:

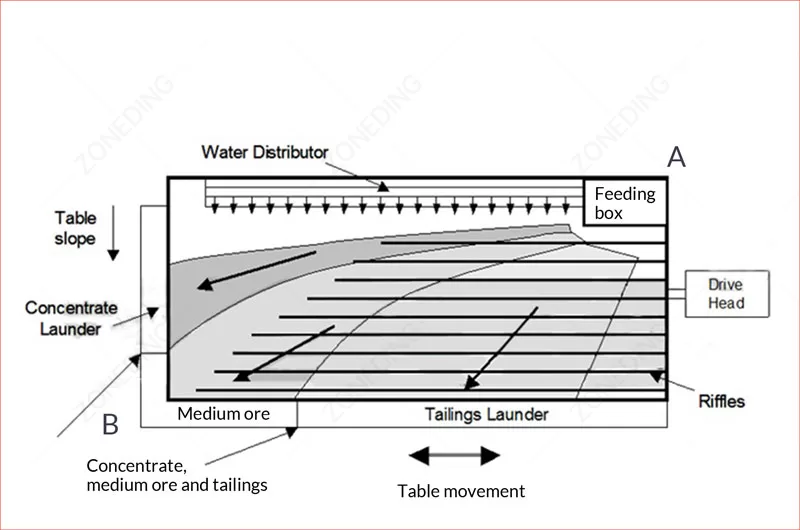

The shaking table work principle is straightforward: material is fed onto a tilted, riffled deck that vibrates. The vibration, combined with water flow, stratifies particles based on density. The result is heavier particles concentrate at one end, with lighter particles washing away, making it the perfect means of capturing gold in tables.

The shaking table of ZONEDING machine mainly relies on its unique shaking trajectory and bed design to realize the separation of minerals. When the motor starts, the power is transmitted to the crankshaft of the shaking table through the transmission device such as belt or gear. The crankshaft then rotates, driving the connecting rod and rocker for up and down or back and forth reciprocating motion. This movement makes the bed surface produce certain vibration and tilt, so that the mineral particles in the bed surface for layering and movement.

As mineral particles of different densities have different settling speeds under the combined effect of vibration and water flow, they will be gradually stratified and moved to different positions on the bed in the order of density from low to high. Eventually, by adjusting the tilt angle of the bed and vibration parameters, the mineral particles of different densities can be discharged from the concentrate and tailings ports of the bed, thus realizing the effective separation of minerals.

Here are the key steps in the shaking table work principle:

Different types of shaker gold table include Wilfley tables (versatile), Bartles-Mozley tables (high-capacity), and circular tables (space-saving). The various configurations of shaker gold table machines allow for flexibility depending on the needs of your operation.

Types of shaker gold table:

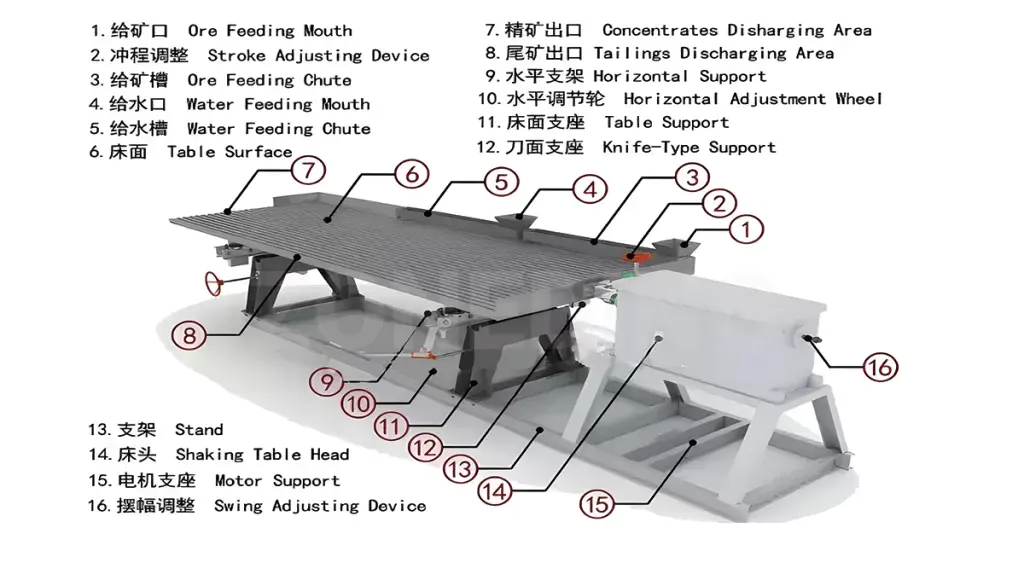

The structure of a gold shaker tables includes a deck (the separation surface), a head motion mechanism (for vibration), a frame (for support), and a feed/water distribution system. These components combine to create a reliable gold shaker table.

Key components of a gold shaker tables:

Specifications for a gold shaker table for sale include deck size, capacity, stroke length, stroke frequency, and water flow rate. Ensure you weigh each specification carefully to fit your specific processing demands.

Here are the things to consider when selecting a gold shaker table for sale:

Beyond gold recovery, shaker tables handle recovery of minerals such as tin, tungsten, tantalum, niobium, and chromite. Shaker tables extend into recycling and separating materials, not just in gold processing.

Shaking table is one of the main equipment of gravity separation, widely used in separating tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold and other rare metals and precious metal ores, and can also be used in coal mines. 6-S shaking table can be used in different operations such as roughing, selecting, sweeping, etc., and separating different particle sizes, such as coarse sand (2-0.5mm), fine sand (0.5-0.074mm), slime (-0.074) and so on. It can also be used for separating iron, steel, and other minerals. It can also be used for separating iron and manganese ores and coal. When dealing with tungsten, tin and other ores, the effective recovery particle size of shaking table ranges from 2-0.022mm.

Shaker table application beyond just gold recovery:

Minerals applicable in shaking tables include gold, silver, tin, tungsten, chromite, lead, zinc, and more. The determining factor for separation is the differential between densities of target minerals and other materials.

Key minerals that can be separated by shaking tables:

Shaking tables compare well to other gold recovery methods by offering high efficiency and ability to process fine particles compared to panning and sluicing. The shaker table excels where other gold recovery methods like cyanidation might be too complex or harsh.

Comparison points for shaking tables:

To choose the correct shaking table for your gold mining operation, factor in feed particle size, desired capacity, and differences in specific gravity. It would also be wise to evaluate your budget and available workspace.

Key factors for picking your shaking table:

Shaking tables from ZONEDING are known for being robust, fully adjustable, and providing high gold recovery rates. The tables are designed to handle many materials and will provide reliable performance for years to come.

Features you’ll find on ZONEDING shaking tables:

The price of shaking tables will vary. A small gold shaker table can be a few thousand dollars, whereas larger, industrial options can cost tens of thousands depending on their features. ZONEDING Shaking Tables price range is from USD1200-USD1500.

Factors influencing shaking table costs:

To operate a shaking table effectively, you need proper preparation. Adjust the stroke, control the water, and monitor the output to ensure optimal efficiency. Gold finishing table operations require great care.

Operating steps for maximum effectiveness:

Maintenance for shaking tables involves regular lubrication of moving parts, inspection for damage, and keeping the water distribution system clean. Shaker table gold operations should take great care to be consistent and thorough in their maintenance schedule.

Core maintenance tasks for your shaking table:

Common issues with shaking tables include uneven distribution, wear on the deck, motor problems, and separation inefficiencies. Proper operation will extend the life of the equipment.

Most common issues with shaking tables:

Choose ZONEDING for reliable gold shaker tables that produce consistent performance backed by our expertise and constant support. We offer tailored solutions to meet your mineral processing demands.

Why choose ZONEDING shaking tables?

A gold mining operation increased its gold recovery by 20% after installing ZONEDING shaking tables, allowing them to capture fine gold particles, thus leading to improved yields.

Professional gold leaching agitation tanks for CIL and CIP processes. Durable, wear-resistant impellers for reliable mineral processing. Request a custom layout!

Your reliable source for high-capacity, heavy-duty ball mills engineered for mining, cement, and fine powder processing.

Zongding Machinery provides advanced ball mills and mineral processing equipment to help mining companies around the world process minerals more efficiently.

the best Ceramic Ball Mill manufacturers and their competitive prices. Our selection offers top-quality mills for various applications at affordable costs.

Efficient flotation machine for mineral processing at competitive prices. Maximum recovery and optimal grade for your mining operations.

A magnetic separator is a device that separates magnetic minerals from nonmagnetic minerals by applying a magnetic field.

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

“Optimize mineral processing with our high-efficiency Jigging Separator Machine! Ideal for gold, tin, coltan separation.

Gold Mine Wet pan mill applys in the gold mining industry and is one of the indispensable equipment in the modern gold mining industry. In addition, it can also apply for mining and processing other non-ferrous metals and precious metal ore…

Designed to improve complete classification schemes, hydrocyclone meet a wide range of needs, balancing the cost of milling circuits with the performance of the equipment.

loading…

已经是到最后一篇内容了!