Sawdust Dryer

Sawdust dryer is used for pellet sawdust or powder sawdust. Wet materials are continuously sent into the drum through a screw conveyor and then get separated and pushed by the high-speed hot flow. The moisture in wet materials is taken away in this process and then we get powder or pellet dry materials.

- Capacity: 1.5-12 t/h

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source:biomass, natural gas, diesel, coal, etc.

- Application:Widely used for drying sawdust, wood chips, pasture, wood shavings, straw and other materials etc.

What is Sawdust Dryer?

Sawdust dryer is one type of rotary dryer that is specially designed for drying sawdust, wood chips, straw and charcoal, etc. It has high drying intensity, short drying time, large production capacity, high efficiency, small occupied area, easy operation and maintenance, etc. It is also known as sawdust drying machine or sawdust rotary dryer. Mainly, there are two types of sawdust dryer machine named as airflow sawdust dryer and three-channel dryer. The latter is generally used in the sawdust drying process.

Applications of Sawdust Rotary Dryer

Sawdust refers to as the dust, chips, shavings and other materials left when wood is processed. Dried sawdust is widely used as fuel, filler, etc. As a result, sawdust dryer machine is also applied to many fields as follows:

Fuel processing: dried sawdust when briquetted is the key raw material in the fuel industry, like in heating supply system, power plant and so on;

Furniture industry: sawdust rotary dryer is used to dry the wet sawdust to a certain humidity, which is for the shaving board making, plywood making, etc.

Paper Making Industry: dried sawdust can be the raw material when make paper, therefore, this sawdust drying machine plays an initial part;

Edible fungus cultivation: the sawdust which is dried to the required moisture can be to cultivate mushrooms, fungus mushrooms, needle mushroom and agaric mushroom.

Structure and Benefits of the Sawdust Dryer

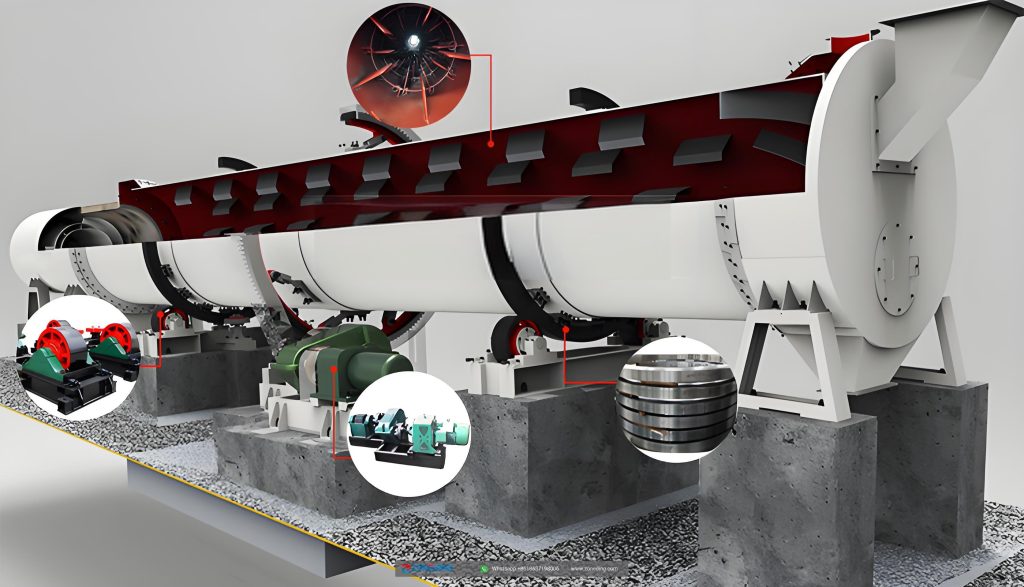

Sawdust Dryer is mainly composed of a heating furnace, inlet, rotating cylinder, filtering cylinder, conveying pipe, cooling tube and the outlet.

Small occupied area, easy construction and maintenance, low drying cost. The material is highly dispersed in the airflow dryer; the particle surface is the effective drying area;

Strong drying strength, short drying time, high processing capacity, high thermal efficiency, non-binding water heat efficiency is up to 60%;

Wide scope of applications. The operating parameters can be changed according to the requirements of different customers;

Long service life. The cylinder rolls stably, thus, wearing is reduced.

Working Principle of Sawdust Dryer

1. The sawdust is fully dried in the rotating cylinder;

2. Sawdust is fully dispersed again before entering into the material conveying pipe, so that the evaporation will be faster;

3. The material is boiling in the tube, the hot air and material will fully contact with each other to complete the drying process.

How to Improve the Efficiency of Zoneding Sawdust Dryer Machine

Faced with numerous changes and threats, Zoneding keeps on the research of how to increase the efficiency of the sawdust dryer and finds some tips.

1>> Replace the spiral conveying blades at the feeding end with 6mm steel triangular stiffened plates. It is to lower the sawdust speed in the high-temperature zone and to make a maximum utilization of the heat.

2>> Build central X-shaped lifting blades to prolong the residence time of the material and improve the heat transformation;

3>> Change the angle of the feeding tube. With the standard of not to influence the feeding efficiency, lift the blanking cylinder as much as possible. The top of the lifted tube shall not touch the material retaining ring. The part of the tube inside the cylinder shall be not too long and the material falls within the 200mm of the retaining ring. Thus, a material screen is formed and heat transformation is enhanced.

General Specification

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine