Sand Making MachineFine Crushing

The specific production capacity is based on the customer’s site configuration and actual production capacity.

Feeding Size: ≤40mm

Production capacity: 70-640T/H

【Product Particle:】

The finished product of the sand making plant has a cubic shape and low flake content, which is especially suitable for stone shaping and producing mechanism sand.

【Applicable Fields:】

A vertical shaft impact crusher is mainly used for crushing and shaping non-metallic ores, construction materials, artificial sand, and various metallurgical slag.

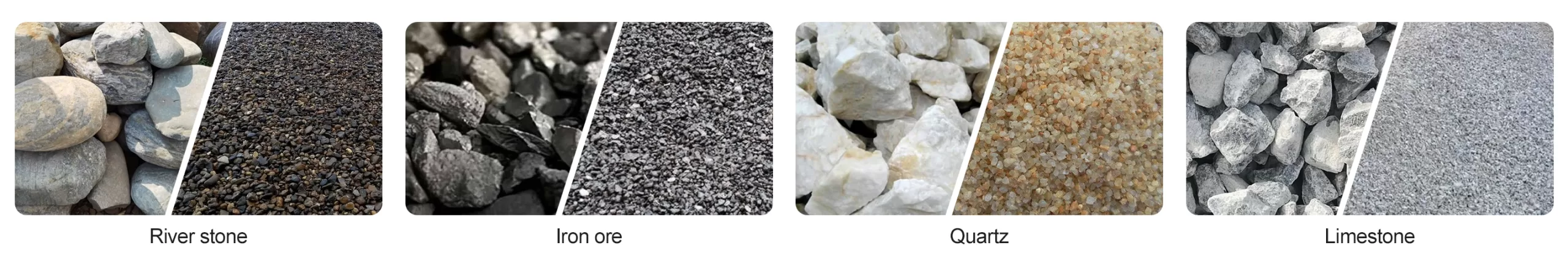

【Processing Materials:】

The materials that can be processed by sand making crusher machine are limestone, river pebble, mountain stone, lapis lazuli, cobblestone, weathered sand, basalt, granite, quartz, gabbro, etc.

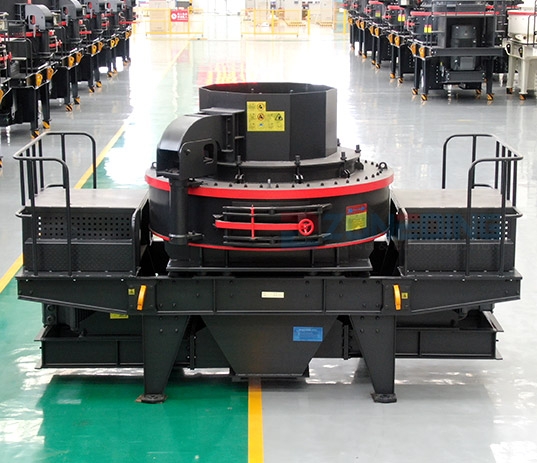

What is a sand making machine?

A sand making machine, also known as a vertical shaft impact crusher, is a type of equipment used to crush or shape rocks into sand particles. Its main purpose is to produce well-shaped sand products that can be used as a substitute for natural sand.

Applications of sand making machine

- Artificial sand making: processing river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips, and other materials.

- Construction use: construction aggregate, highway road fabric, bedding material, production of asphalt concrete and cement concrete aggregates.

- Engineering use: engineering field of water conservancy and hydropower, high-grade roads, highways, high-speed railroads, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise construction of the production of mechanism sand and stone shaping.

- Mining industry: fine crushing process in the pre-mill section of the mining industry, material crushing in building materials, metallurgy, chemical industry, mining, refractory materials, cement, grinding materials, and other industries.

Production Process Of Sand Processing Plant

The sand making product line follows a systematic process. Here’s a clear and structured breakdown of the steps involved:

- Stone Crushing: Large stone pieces stored in the silo are fed into the jaw crusher by a vibrating feeder for coarse crushing. The crushed materials are then conveyed by a belt conveyor to a cone crusher or impact crusher for further crushing.

- Screening: The belt conveyor transports the crushed materials to a vibrating screen for screening. The vibrating screen separates the finished sands (materials above the sieve) from the oversized particles (materials under the sieve).

- Sand Washing: The finished sands are carried by a belt conveyor to a sand washing machine for washing and removing impurities. After washing, the cleaned sands are sent to the finished product stack with the help of a belt conveyor.

- Fine Crushing: The oversized particles (materials under the sieve) are conveyed by the belt conveyor to a vertical mobile impact crusher (artificial sand making machine for sale) for fine crushing. The finely crushed stones are then sent back to the vibrating screen for another round of screening.

This process forms a closed loop where the materials go through repeated crushing and screening stages until they meet the desired size and quality requirements. The rock crusher equipment continues until the desired amount of sand is produced. By following this structured sand processing line, sand manufacturing machines efficiently crush, screen, wash, and refine raw materials to produce high-quality sand products. Let’s take a look at a real case.

Types of sand making machine

1. VSI series sand making machine

VSI sand making machine is a common gravel-making machine in the market. VSI sand maker has a deep cavity rotor design with a large passing capacity. Compared with traditional sand making

Maximum feed size:Hard material <45 mm, soft material <50 mm

Capacity (feed at center):40–365 t/h

Capacity (feed at center and sides):80–650 t/h

Motor power:4P 500 kW

2.PCL series sand making machine

PCL sand making machine is the latest equipment with two functions of sand making and shaping. The finished product is uniform, with a beautiful size and better grain shape. It adopts the best design of the material impact angle of the crushing chamber.

Maximum feed size:Hard material <50 mm, soft material <55 mm

Sand shaping capacity:50–498 t/h

Sand making capacity:90–585 t/h

Motor power:2×315 kW

3. Mobile sand making machine

Both PCL and VSI sand making machines can be equipped with mobile crushing stations. The mobile sand making machine can be driven to the site to start sand making and screening work directly. It not only effectively improves work efficiency, but also facilitates user operation.

Production capacity:40-650 t/h

Equipped with machines:Feeder, sand making machine, vibrating screen, conveyor, etc.

It can be composed of tire-type and crawler-type sand making machines to meet the needs of various coarse, medium, and fine sand production plants.

How does a sand making machine work?

Here’s a detailed breakdown of its working mechanism:

Material Intake:

Raw material flows into the vortex crushing cavity from the feed hopper.

This material is typically rock, gravel, or other hard substances suitable for sand production.

High-Speed Rotation and Impact Crushing:

Inside the machine, a high-speed rotating impeller functions as the main crushing component.

As the impeller rotates at high speed, it scatters the material around it in an umbrella-like pattern, effectively crushing it.

Multiple Collisions and Friction:

The scattered materials collide with each other, undergoing further fragmentation.

A vortex flow is created within the material layer between the impeller and the casing, leading to multiple collisions, friction, and additional crushing.

Discharge and Screening:

Crushed material is discharged from the lower discharge hopper, completing the crushing process.

A screening machine is then used to control the particle size of the finished product, ensuring that it meets the desired specifications.

This process allows for efficient and controlled sand production, which is crucial in various construction and industrial applications. The sand making machine’s ability to crush and refine materials quickly and effectively makes it a valuable piece of equipment in the sand and gravel industry.

General Specification

Sand Making Machine

| Model | Sand Shaping | Sand Making | Sand Shaping | Sand Making | Motor Power(kw) |

| Max.Feeding Size (mm) | Throughput(t/h) | ||||

| PCL 0815 | <30 | <35 | 70-140 | 130-230 | 2×75 |

| PCL 0818 | <30 | <35 | 80-190 | 165-283 | 2×90 |

| PCL 0922 | <35 | <40 | 105-145 | 220-330 | 2×110 |

| PCL 0926 | <35 | <40 | 120-190 | 240-380 | 2×132 |

| PCL 1032 | <40 | <45 | 181-278 | 246-356 | 2×160 |

| PCL 1040 | <40 | <45 | 262-284 | 350-440 | 2×200 |

| PCL 1250 | <45 | <50 | 345-371 | 414-540 | 2×250 |

| PCL 1263 | <50 | <55 | 453-498 | 521-585 | 2×315 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

Vibrating Feeder

What is Vibrating Feeder?Applications of ZDM Vibrating FeederHow Vibratory Feeder WorkAdvantages of Vibrating Feeder MachineGeneral SpecificationVibrating FeederFAQRelated Products Vibrating Feeder The vibrating feeder (vibratory feeder) is suit…

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine…

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine