Sand Dryer

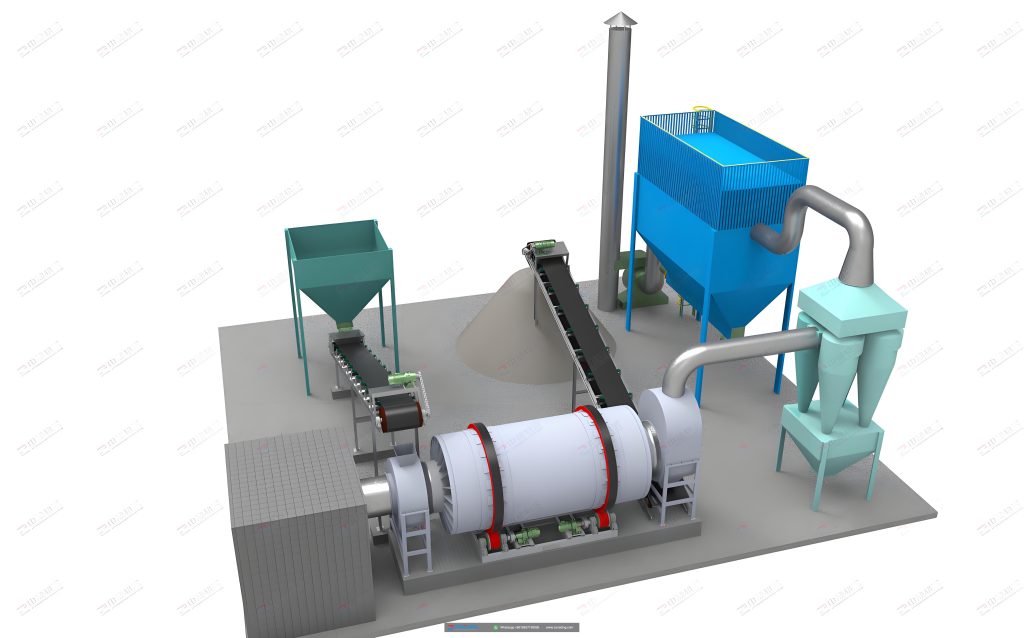

Sand dryer, also known as the three layers of drum dryer or three return cylinder dryer, is developed and manufactured based on the single-cylinder dryer. It’s an industrial dryer for non-viscous, liquid material.

- Capacity: 5-100 t/h

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source: biomass, natural gas, diesel, coal, etc.

- Application: Suitable for drying the sand, silica sand, fly ash, mineral slag and other material.

What is Sand Dryer ?

Sand dryers can be classified based on two main factors: volume and the materials to be dried.

Sand dryer is a drying equipment for dehydrating granular materials, especially suitable for artificial sand, river sand, quartz/silica sand, etc. The dryer has the advantages of high production capacity, wide range of application, small flow resistance, large operation fluctuation range, and convenient operation. Sand dryers are also commonly used to dry mineral powder, cinder, slag, etc. The sand dryer is suitable for a variety of fuels, such as coal, oil, and gas.

Classification of sand dryers

According to the body integration, sand dryers can be divided into large sand dryers and small sand dryers; According to the materials to be dried, it can be divided into silica sand dryer, quartz sand dryer, river sand dryer, yellow sand dryer, zircon sand dryer, garnet sand dryer, etc.

Application of Sand Dryer

- Artificial sand, river sand, quartz/silica sand, yellow sand, etc. in building materials;

- Iron powder, zinc ore powder and other mineral powders in the beneficiation process; fly ash, limestone and other particles in the cement industry;

- Raw coal powder, semi-coke, coal gangue, coal ash, etc. in the coal industry and power plants;

- Other power such as dry-mix mortar, slag, clay, gypsum, chemical industry, foundry and other industries.

Applications of Sand Dryer

Working Principle of Sand Drying Equipment

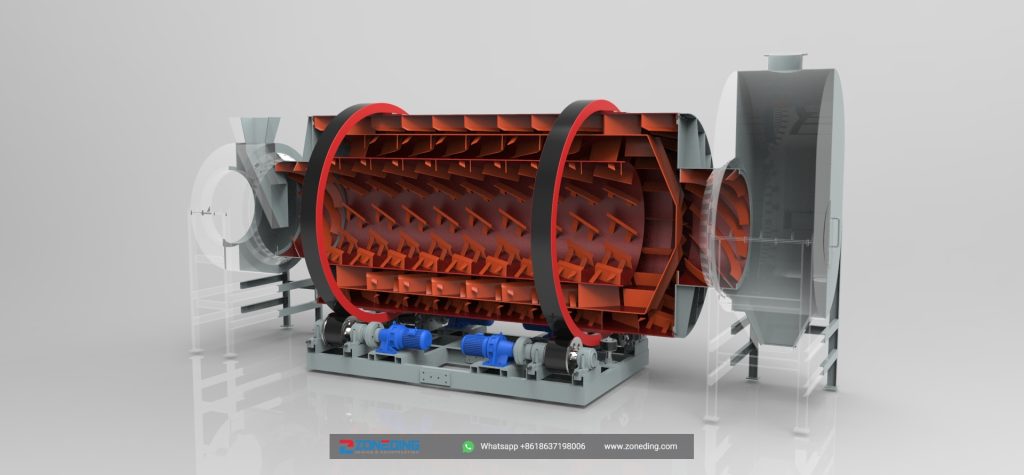

When the sand dryer is running, there are three main systems working, the boiler system, the heat exchange system and the dust removal system. The first system uses hot blast furnace technology. The heat exchange system mainly refers to a three-cylinder drum in which the wet sand is lifted in full contact with the gale. The lifting blade fixed to the inner wall has a spiral-shaped structure. Dry materials are easily blown away by flowing air. Here, the dust collector gets to work to avoid waste of resources or air pollution.

Working Principle of Sand Dryer

Structure And Advantages of Rotary Dry Sand Machine

The sand dryer is mainly composed of a rotary cylinder, air induction equipment, high-speed scattering equipment, lifting plate, automatic cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support and sealing device, etc.

Exquisite workmanship: wear-resistant manganese plate is used, and the wear resistance is 3-4 times that of ordinary steel plate;

Stable performance and advanced technology: the output humidity of the sand can be controlled below 0.5-1% according to your requirements, and the sand in the dryer can maintain its quality;

Small footprint and reasonable design: compared with traditional dryers, the new sand drying equipment covers 60% less area;

Other advantages: low maintenance costs, low energy consumption, high degree of mechanization.

Precautions for Installation In The Sand Dryer

>> The sand dryer should be installed on a horizontal concrete bed and fixed with anchor bolts;

>>The main body of the rotary dry sand machine should be perpendicular to the horizontal ground;

>>Check each anchor bolt and door of the main machine to see if it is locked;

>>Distribute wires and control switches as instructed;

General Specification

Sand dryer

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder(m) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder(m) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume( m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder(rpm) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag(%) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag(%) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground(%) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (%) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature(℃) | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ | 700-750℃ |

| Production capacity(T/h) | Yellow sand:25-30 Slag: 20-25 | Yellow sand:30-35 Slag:25-30 | Yellow sand:35-40 Slag:30-35 | Yellow sand:45-50 Slag:35-40 | Yellow sand:65-70 Slag:60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine