Rod Mill

- Capacity:0.62-180t/h, Customizable

- Feeding Size:<25mm; According to Model

- Discharging Size:0.075-0.4mm; According to Model

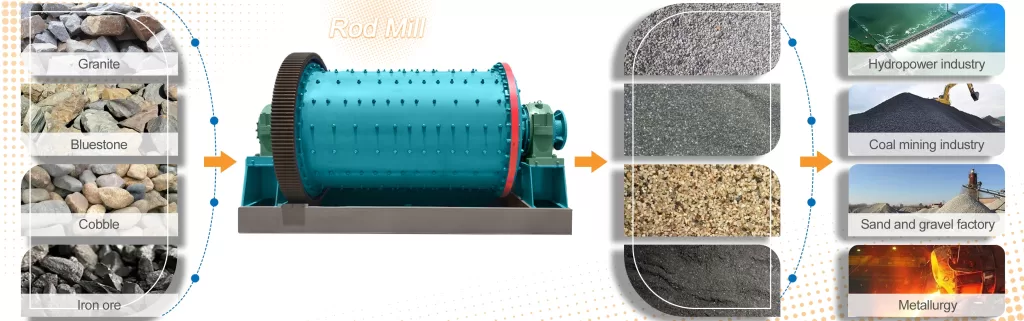

- Applied Materials:Quartz stone, iron ore, copper ore, gold ore, construction waste, cement clinker, pyrrhotite, hematite, limonite, etc. Mainly used to smash all kinds of ores and raw materials.

Rod Mill For Sale

The rod mill is a grinding equipment that uses steel rods as the grinding media, widely used in metal and non-metal mines, water conservancy, building materials, chemicals, refractories, metallurgy, glass, and other industries. This equipment adopts advanced controllable feeding and discharging technology, combined with actual grinding materials, and is equipped with suitable grinding bodies to change the traditional surface contact to line contact, resulting in more uniform discharge particle size and higher production capacity. Rod mills are available in both dry and wet forms for users to choose according to their actual situations.

Table of Contents

Working Principle of Rod Mill

The working principle of the rod mill is to drive the rotation of the cylinder through the motor and the surrounding large gear reduction transmission. The interior of the cylinder is equipped with appropriate grinding media – steel rods. The grinding media is lifted to a certain height under the action of centrifugal force and friction and falls in a throwing or leaking state. The material to be ground continuously enters the interior of the cylinder through the feed port and is crushed by the moving grinding media. The product is discharged outside the machine through the force of overflow and continuous feeding for the next process operation.

Product Features of Rod Mill

- High efficiency and energy saving: Advanced controllable feeding and discharging technology and suitable grinding bodies are used to make the discharge particle size more uniform and increase production capacity. At the same time, the equipment can use rolling bearing support instead of bush sliding bearing support, using dry oil lubricating grease instead of thin oil lubrication station, saving 10-20% of energy.

- Superior particle shape: During the grinding process of the rod mill, the grinding media and the ore are in line contact, so they have a certain selective grinding effect. The product particle size is uniform, and there are few over-crushed ore particles. When processing coarse-grained materials, the processing capacity of the rod mill is larger than that of the ball mill of the same specification.

- User-friendly design: The equipment adopts an automatic centralized lubrication system to avoid thin oil pollution, reduce equipment failure rate and operator maintenance costs, and improve the production efficiency of the whole machine.

- Wide application: Rod mills are suitable for grinding operations of ores and rocks with different hardness (Mohs hardness 5.5-12), meeting the requirements of various ore crushing and artificial sand making operations. They are widely used in mining, water conservancy and hydropower, building materials, chemicals, and other industries.

- Stable and durable: The main body of the rod mill is a low-speed rotating cylinder horizontally mounted on two large bearings, with a stable structure, smooth operation, and long service life.

- Easy to operate: The equipment is simple and convenient to operate, easy to master. It adopts an automatic control system, which can realize remote monitoring and operation, reducing labor intensity.

Rod Mill shipment

If you are interested in this, please contact us as soon as possible! We will provide you with more than 2 solutions for you to choose from.

Parameters of Rod Mill

Rod mill

| Model | Shell rotation speed(r/min) | Feeding size(mm) | Discharging size(mm) | Processing capacity (t/h) | Power (kw) | Total weight (t) |

| MBS0918 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

Service Support of Rod Mill

We provide comprehensive pre-sales, in-sales, and after-sales service support, including technical consultation, scheme design, equipment installation and debugging, operation training, and maintenance. Our goal is to provide customers with the best quality products and services to ensure smooth production.

FAQ

1.Are you a manufacturing or trading company?

We are manufacturer. Our factory established in 2004.

2.What is the after-service of your company?

We can provide the foundation drawing, installation service, training, spare parts and other service according to the customer’s requirements.

3. Which mineral processing method should I choose?

According to the properties of minerals, we will choose the treatment method that most suitable for you.

4. What machines are usually required for the whole production line?

Usually there are feeder, primary and secondary crushers, vibrating screen, ball mill, classifier, spiral chute, magnetic or flotation machine, dryer, etc. Equipment can be adjusted.

5. What is the final mineral concentration?

It depends on the ore grade. The final concentration of gold ore can reach 80-90%.

Related Products

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine