Phosphate ball mill working principle, structure, phosphate ball mill steel ball loading capacity

The phosphate ball mill is a specialized ball mill designed for grinding phosphorus ore based on its physical and chemical properties. It has a very good grinding effect on phosphorus ore, which is beneficial for the comprehensive utilization of phosphate resources.

Working principle of phosphate ball mill:

- The raw phosphorus ore is crushed to a particle size of ≤25mm by a crusher.

- The crushed ore is then fed into the ball mill through the feeder inlet.

- The ball mill starts running under the drive of the motor and reducer. The torque is transmitted to the ball mill cylinder through the large and small gears.

- The phosphorite and steel balls in the cylinder rotate together with the cylinder. The liner plate lifts the steel balls to a certain height, and the impact of the steel balls on the phosphorite leads to crushing.

- The remaining steel balls produce friction and mix with the material, and with the rotation of the cylinder, the phosphate material undergoes collision and grinding.

- The fine phosphorus after grinding is discharged from the discharge port based on the mobility of the phosphate material.

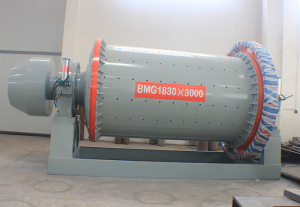

Structure of phosphate ball mill:

The structure of the phosphate ball mill is similar to that of an ordinary ball mill, consisting of feeding part, discharging part, rotating part, and transmission part (including reducer, small transmission gear, motor, and electric control).

Phosphate ball mill steel ball loading capacity:

The steel ball loading capacity of the phosphate ball mill is an important factor that directly affects the grinding effect. Generally, the ball loading of the phosphate ball mill is around 40% of the cylinder volume, with a filling rate of about 35% during production. This ensures that there is enough space in the cylinder for the steel balls to fall and generate a greater impact to achieve the desired particle size.

For example, in a 1200×2400 phosphate ball mill with an effective cylinder volume of 3.8m³, the recommended ball loading capacity is around 7.8t.

The phosphate ball mill comes in various models, ranging from small diameters of 0.6m to large diameters of 4.5m. Customization according to specific needs is possible.

If you have any further questions, please feel free to contact us!

Zoneding Machine

Zoneding Machine