Search the whole station Crushing Equipment

Lignite is a low-grade coal with a low degree of coalification, characterized by colors like brown and dark brown and a lack of cohesion. It has properties between peat and bituminous coal, with high water content, high volatility, low density, and a high oxygen content that makes it prone to fragmentation and spontaneous combustion.

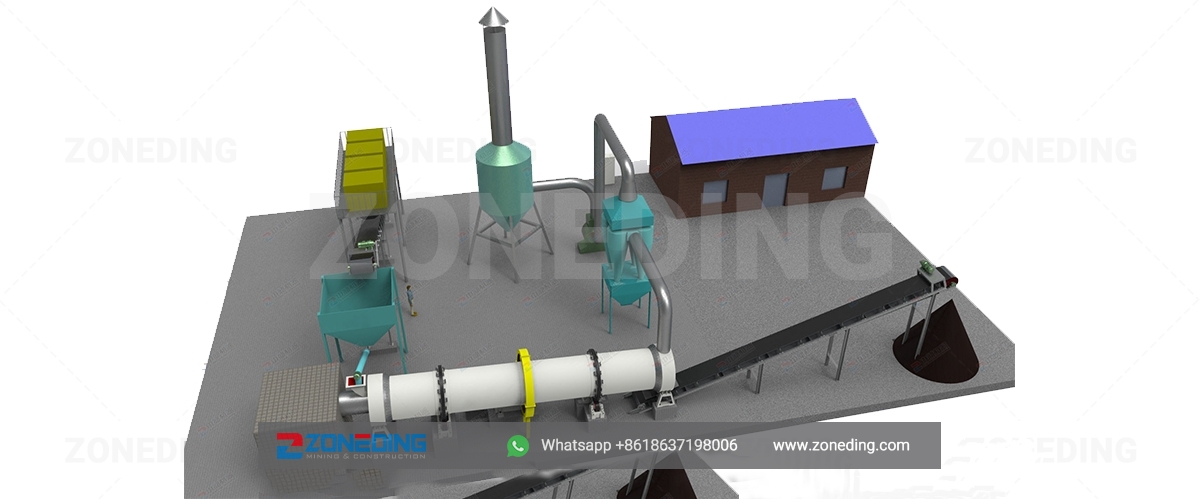

Lignite dryer machine is a kind of rotary equipment for dewatering lignite coal. Lignite dryer is also called brown coal dryer and wood coal drying machine, which can realize continuous, industrial and automatic operation. It is designed specially targeted at lignite characteristics. Zoneding lignite dryer was born with aim to meet environmental legislation and customers’ need.

To guarantee the quality of lignite and coal slime unchanged after the drying process, Zoneding engineers keep researching and have developed advanced lignite drying technology. Zoneding focuses on controlling the scorching wind temperature and rotating speed to reach higher drying efficiency. Lignite coal dryer machine can dewater the coal slime to the moisture content below 13%, and improve the combustion efficiency.

Why Dry Lignite?

Lignite is a kind of mineral coal with minimum coalification degree. Because it is rich in volatile elements, it is easy to be burnt and generate smoke. Besides, lignite contains about 6-19% ash, which makes it pollute the environment a lot when burning. Therefore, washing process is needed to improve the purity.

In addition to this physical characteristic, it is of high moisture and easy to self-ignite, which is a big issue for storage and transportation. Sometimes, good coal cannot meet the fuel requirement, for which lignite is in large demand as an alternative.

In view of the above, lignite drying machine is born and become requisite. Dried lignite is mainly used in thermal power plant, chemical industry, metal recycling as well as catalyst supports, adsorbents, sewage purification etc. And the lignite dryer machine can also be used for drying fly ash, coke, coal as well as other granular, paste and powder materials.

Lignite Dryer adopts the new technology of drying after crushing, which realizes the industrialization, automation and continuous production. When the lignite dryer machine works, wet lignite is fed into the crushing equipment firstly. Then low-temperature four-stage drying process is introduced and dries the wet lignite to the humidity of 13% or below.

Working Principle of Lignite Dryer

First Level: 400 ℃, high temperature removes most of the moisture and make sure the lignite not change chemically;

Second Level: 300 ℃, strong wind produced works in high efficiency to ensure that the lignite is not coking;

Third Level: 120-210℃, with the crushing function of the cleaning devices inside the cylinder, wet lignite flows in the cylinder and is dried;

Fourth Level: 60-80℃, the removal of water depends on low-temperature current produced by the induced draft system.

Therefore, lignite dryer can take full advantage of the coal resources and reduce the emission concentration, so as to achieve energy-saving emission reduction and environmental protection objectives.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

ZONEDING MACHINE focuses on material processing equipment manufacturing. Post-processing gypsum is often wet and difficult to handle. Our Gypsum Dryer is an efficient drying solution, bringing your gypsum to quality standards and making it …

After high-temperature processes, like those in a Rotary Kiln, materials are very hot. They need cooling before you can handle or store them. They need cooling before the next steps like grinding in . The Rotary Cooler does this job. It coo…

The Rotary Kiln is a very important machine in many big industries. It uses very high heat to change materials. People use it for making cement, processing minerals, and treating waste. It is a big, rotating cylinder. …

Zoneding Company conducted technical research on sludge treatment, created a new generation of sludge rotary drum drying system that can reduce product moisture to less than 25%, with mature technology and easy operation and maintenance. …

Sand dryer, also known as the three layers of drum dryer or three return cylinder dryer, is developed and manufactured based on the single-cylinder dryer. It’s an industrial dryer for non-viscous, liquid material. …

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

Privacy Policy