Jigging Separator Machine

- Maximum feed size: ≤6-25mm

- Production capacity: 1.5-25t/h

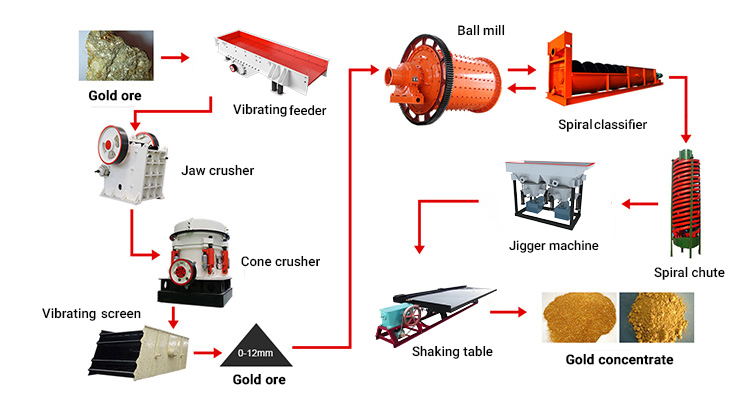

- Materials:The mineral jig separator is widely used in gravity separation process of gold, diamond, coltan, lead-zinc, copper, tin, tungsten, titanium, manganese, tungsten ore, fluorspar ore, iron ore, chrome ore, and other mineral processing plant.

Jigging Machine for sale

Jigging Machine(jig concentrator, jig machine, mineral jig, Jigging Separator) is a mining gravity separation equipment Jig separator are widely used in gravity concentration stage of various heavy metal, metallic and non-metallic mineral separation plant. It can handle a wide range of particle sizes, and has good results from fine to coarse particle size sorting.It has the characteristics of high sorting efficiency, large processing capacity, environmental protection and energy saving. It is the most common gravity separation machine in gold, manganese and diamond processing plants.

Table of Contents

Applications

Jigging Machine are widely used in gravity concentration stage of various heavy metal, metallic and non-metallic mineral separation plant.Many of the jig is diaphragm type, and the stroke and stroke time can be flexibly adjusted according to the specific gravity of the selected mineral. It is used for tungsten, tin, gold, hematite, limonite, manganese, titanium, rare earths, lead, niobium, etc. Equivalent to gravity mineral processing.

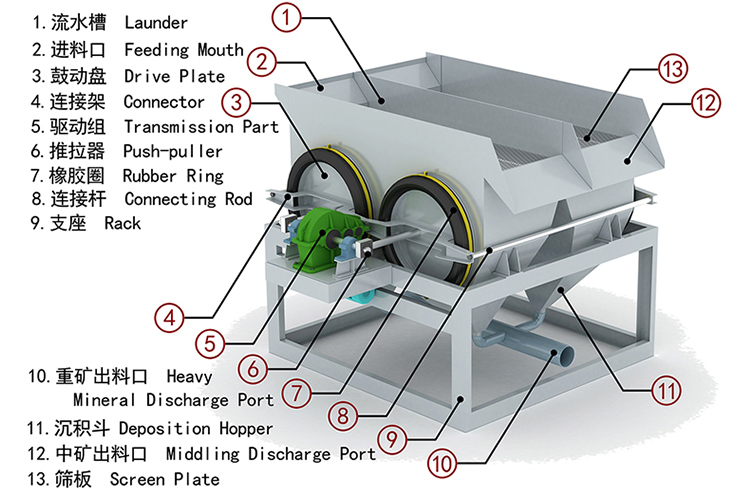

Product Structure

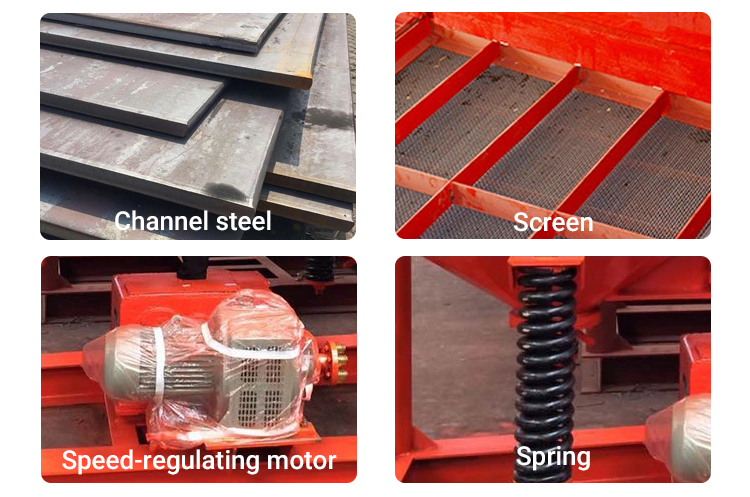

1.Using multi-chamber common use numerical control air valve technology.

2.The jig uses a cone-shaped slide valve, which works reliably, reduces the failure rate by 70%, and consumes little energy.

3.It can meet the sorting needs of different materials and increase processing capacity by more than 20%.

4.More reasonable structure, easy to transport and installation, equipment load reduced by 30%.

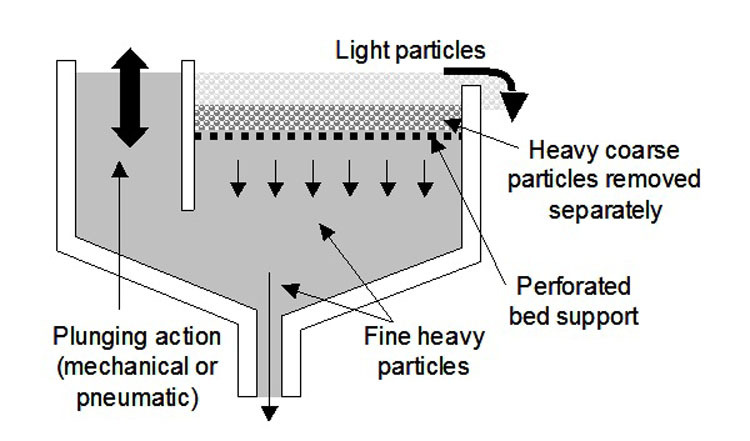

Working Principle

The mineral ore is continuously fed to the screen plate of the jig chamber to form a thick material layer. Rising water is periodically pumped through the sieve plate to loosen the bed, and then the water flows down (or stops rising). During this process, particles with different densities undergo relative transfer. Heavy minerals enter the lower layer, and light minerals move to the upper layer. After being discharged respectively, the concentrate and tailings are obtained.

Parameters of Jigging Machine

| Model | Jig Area (M2) | Stroke (R/Min) | Feeding size (mm) | Hutch Water ( T/H) | Pressure Water (kg/cm2) | Capacity;(T/H) | Power;(KW) | Overall dimensions (mm) | Weight (T) |

| JT0.57-1 | 0.57 | 60-160 | <6 | 1-2 | ≥0.3 | 1-2.5 | 1.5 | 1560x820x1550 | 0.612 |

| JT1-1 | 1.04 | 60-160 | <10 | 2-3 | ≥0.3 | 4-10 | 2.2 | 1322x1190x1915 | 0.9 |

| JT2-2 | 2.28 | 60-160 | <10 | 2-4 | ≥0.3 | 8-15 | 3 | 3225x1550x2150 | 1.637 |

| JT4-2 | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 7.5 | 4240x1990x2750 | 4.6 |

| JT4-2A | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 8 | 4240x1990x2750 | 4.6 |

| JT5-2 | 4.86 | 80-120 | <10 | 4-10 | ≥0.1 | 10-20 | 7.5 | 3940x2006x2580 | 4.6 |

Jigging Machine customer work site

Related Products

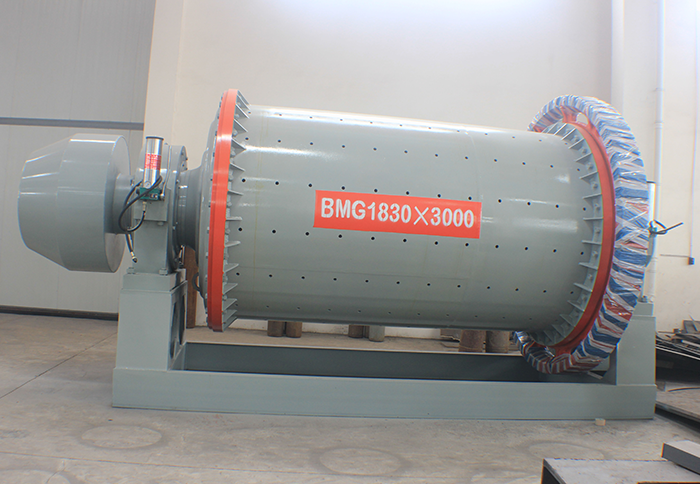

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine