Jaw CrusherCoarse Crushing

A variety of models are available | Get the price list!

- Capacity: 20-800 t/h, customized.

- Max Feeding Size: 125-1200 mm; according to model.

- Motor Power: 5.5-220 kw; according to model.

- Description: Standard jaw crusher output particle size is usually 15-200 mm. It can process bulk materials with a particle size of 1.2 meters.

- Features: Large crushing ratio, uniform product size, safe and reliable lubrication system.

- Applicable Material:Quartz, granite, basalt, limestone, river stone, marble, shale, iron ore, copper ore, gold ore etc.

Jaw Crusher for Sale

Jaw crusher can be used for quartz, granite, basalt, marble, calcite, dolomite, limestone, gypsum, pebble, bluestone, feldspar, glass, cement clinker, concrete, coal gangue, construction waste, copper ore, manganese ore, gold ore, iron ore, and other ores.

Jaw crusher is a new product absorbing world advanced technology, bases on our present traditional jaw crusher, and adopts three-dimensional design theory. Comparing with traditional jaw crusher, it has larger capacity and crushing ratio, bigger range of input size, evener product size, and easier maintenance.

Purpose of Jaw Crusher

Applicable Fields: Widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry.

All Kinds of Jaw Crusher

As ideal primary or secondary crusher equipment, jaw crushers with different types are often used in various industries. Depending on different ways of moving or engine, jaw crushers are divided into three types: PE/PEX Motor jaw crusher, Diesel jaw crusher, and Mobile jaw crusher.

Mobile crushing solutions are also available! You just need to tell our engineer your demand, and we will suggest you the right mobile crushers with low energy consumption, low cost, and high efficiency.

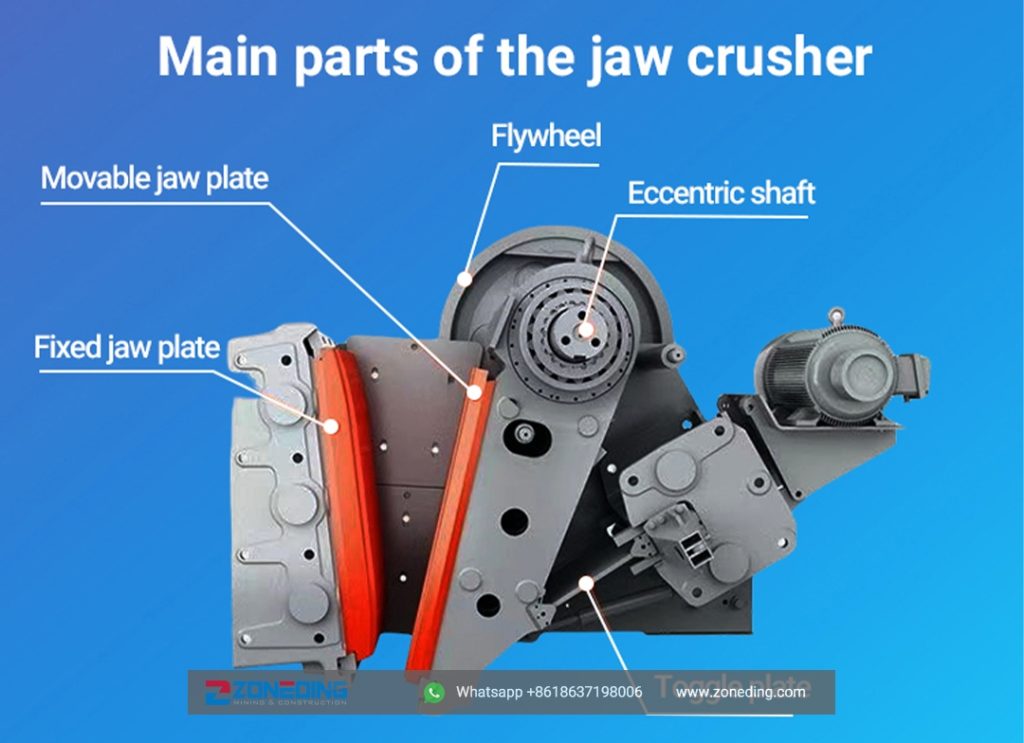

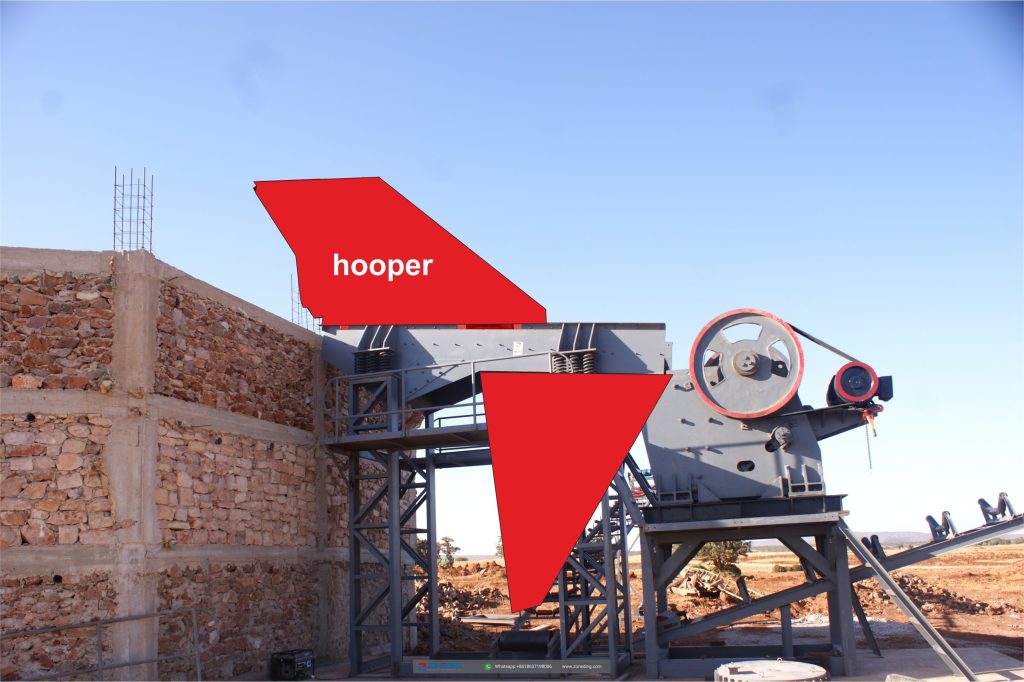

Working Principle of Jaw Crusher

When the jaw crusher is working, the motor starts the V-belt and pulley, and then drives the eccentric shaft to make the movable jaw plate move up and down. The movable jaw plate squeezes and grinds the materials, and the crushed stones gradually fall down. When the particle size meets the requirements, they are discharged by the jaw crusher.

The Advantages of Jaw Crusher

① Deep crushing cavity which improves capacity.

② High crushing ratio and uniform finished production size.

③ Jaw crusher can save power 15% – 30%.

Parameters of Jaw Crusher

| Model | Feed opening(mm) | Max.feeding size (mm) | Outlet opening (mm) | Processing capacity(t/h) | Motor power(kw) | Total weight(t) | Dimensions(mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-22 | 4P 15 | 2.8 | 1450x1350x1500 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 8P 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 8P 110 | 29.8 | 2710×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 8P 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 8P 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 8P 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 6P 160-220 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 8P 280-355 | 139 | 5160×3660×4248 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 6P 55 | 15.6 | 2720×1950×1600 |

Customer Site

FAQ

Q1. Who are we?

A1: ZONEDING is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

Vibrating Feeder

What is Vibrating Feeder?Applications of ZDM Vibrating FeederHow Vibratory Feeder WorkAdvantages of Vibrating Feeder MachineGeneral SpecificationVibrating FeederFAQRelated Products Vibrating Feeder The vibrating feeder (vibratory feeder) is suit…

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine…

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine