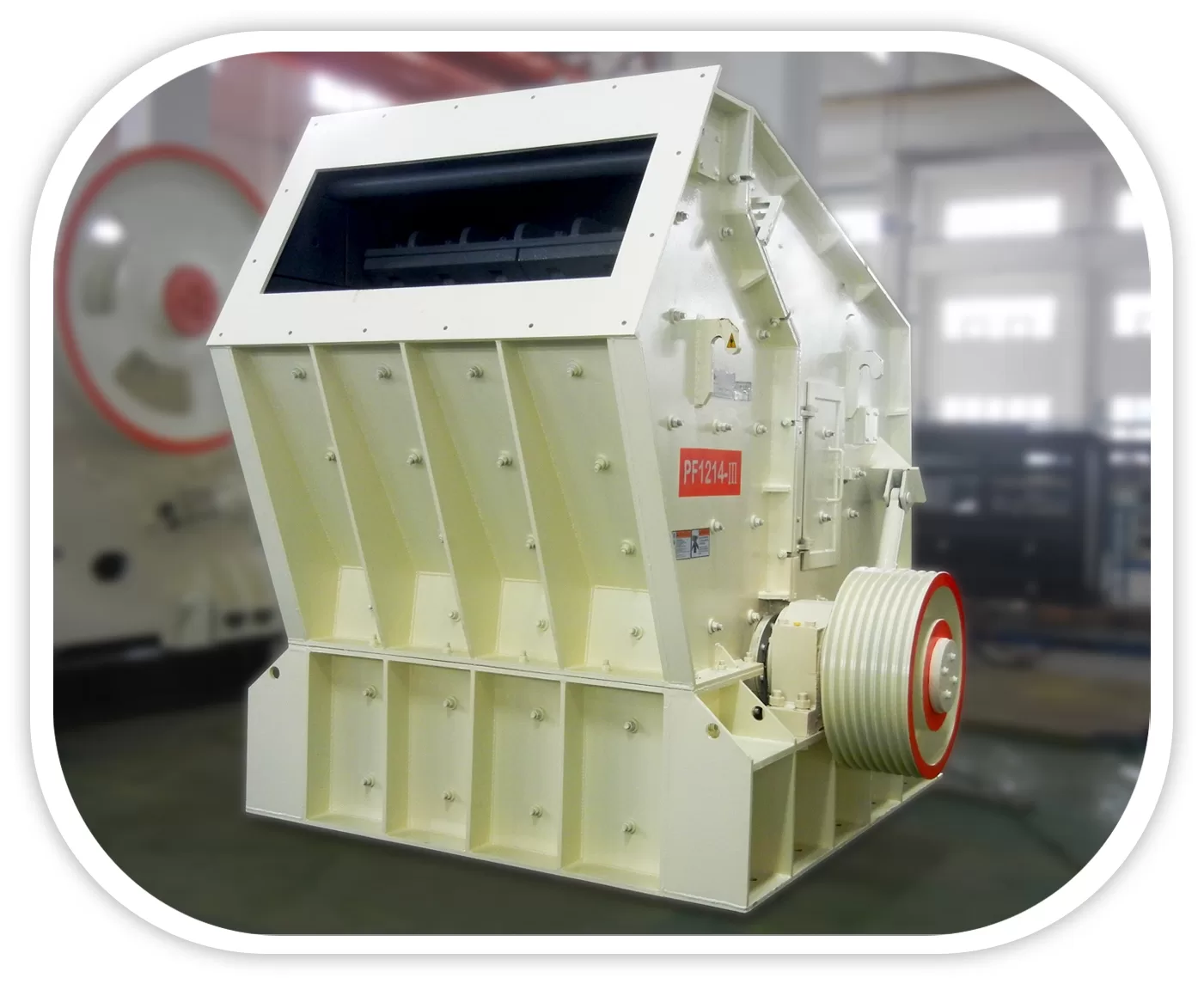

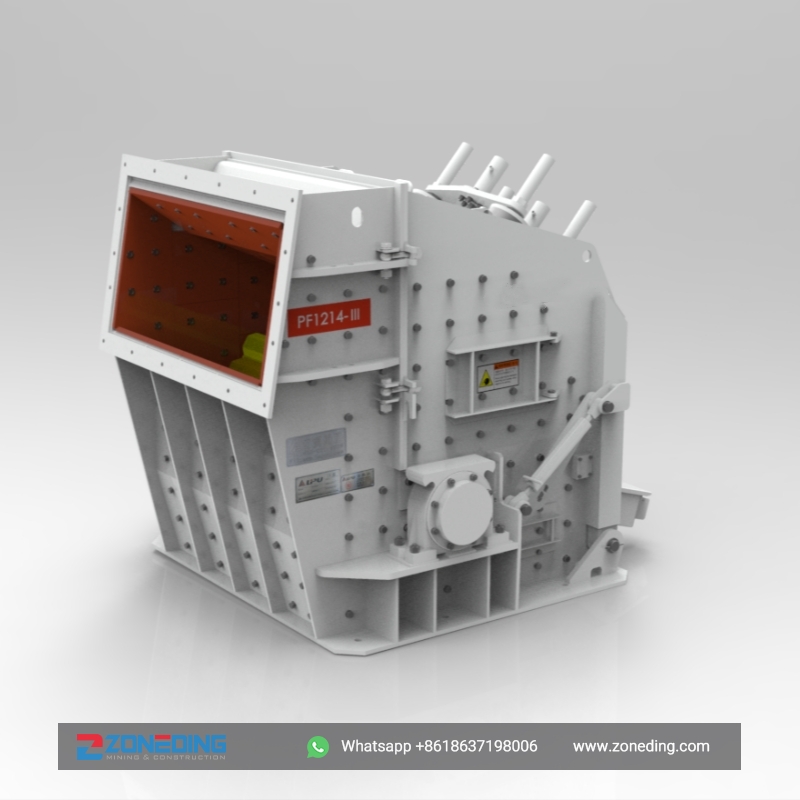

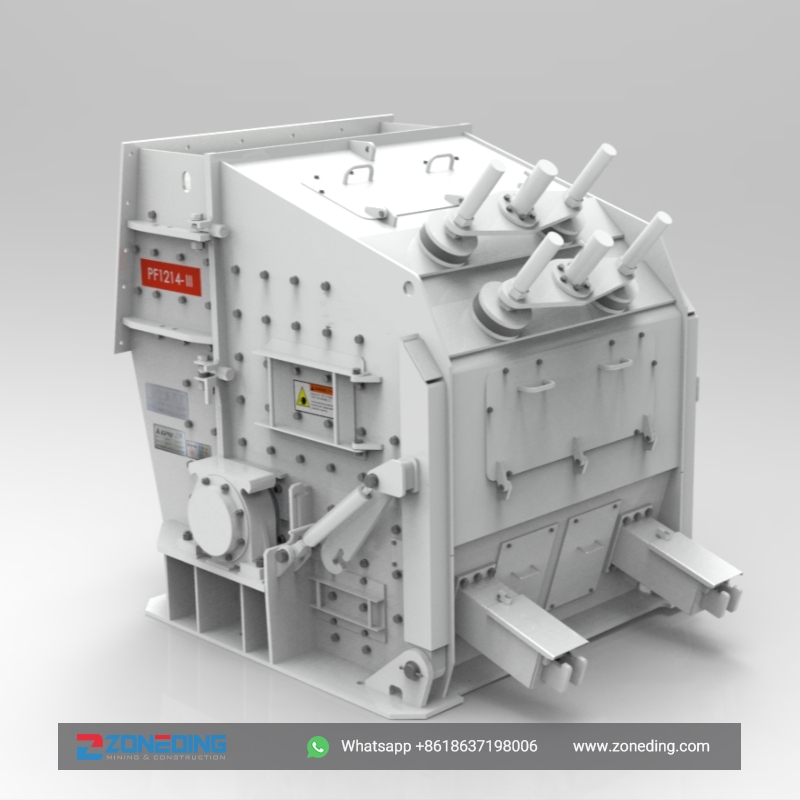

Impact Crusher

A variety of models are available | Get the free price list!

Feed particle size: ≤1000 mm

Capacity: 15-850 T/H

【Applicable Material:】

Limestone, granite, marble, basalt, iron ore, river pebbles, shale, bluestone, coal, pebbles, construction wastes.

【Applicable Fields:】

Widely used in various ore crushing, railways, highways, energy, cement, chemical, construction, and other industries.

What is Impact Crusher?

Impact crusher is a kind of crusher which utilizes impact energy to crush materials. It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with feed size not more than 500mm and compressive strength not more than 350MPa, and is widely used in all kinds of ore crushing, railroad, highway, energy, cement, chemical, construction and other industries. It adopts updated manufacturing technology and unique structural design. The finished product is cubic with no tension or cracks. Our impact breaker series is divided into two series: two-chamber and three-chamber series.

Applications of Impact Crusher

Impact crushers are versatile machines that have a wide range of applications across various industries. Here are some of the main applications of impact crushers:

- Mining and Quarrying: Impact crushers are commonly used in mining and quarrying operations to crush rocks, ores, and other hard materials. They are particularly effective in reducing large rocks to smaller, more manageable sizes.

- Aggregate Production: In the construction industry, impact crushers are used to produce aggregates such as sand, gravel, and crushed stone. These materials are used in concrete, asphalt, and other construction applications.

- Recycling: Impact crushers are also extensively used in recycling applications, where they can process concrete, asphalt, bricks, tiles, and other waste materials. This helps to reduce the amount of material sent to landfills and allows for the reuse of these materials in new construction projects.

- Waste Management: Impact crushers can be used to reduce the volume of waste materials, making them easier to transport and dispose of. They can handle a variety of waste types, including plastics, wood, paper, and more.

- Demolition: In demolition projects, impact crushers can be used to process concrete, bricks, and other materials from demolished structures. This allows for the recycling of these materials and reduces the amount of waste generated by demolition projects.

- Other Applications: Impact crushers can also be used in a variety of other applications, including glass recycling, ceramics production, and the processing of non-metallic minerals.

The versatility and high efficiency of impact crushers make them a valuable asset in many industries that require material reduction and recycling.

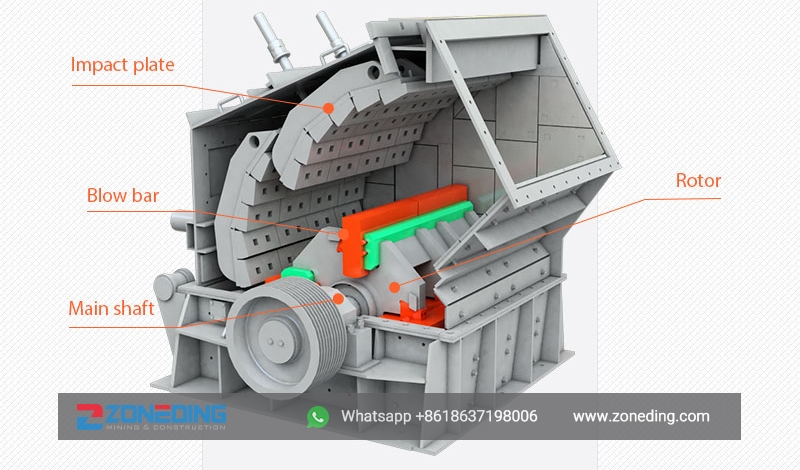

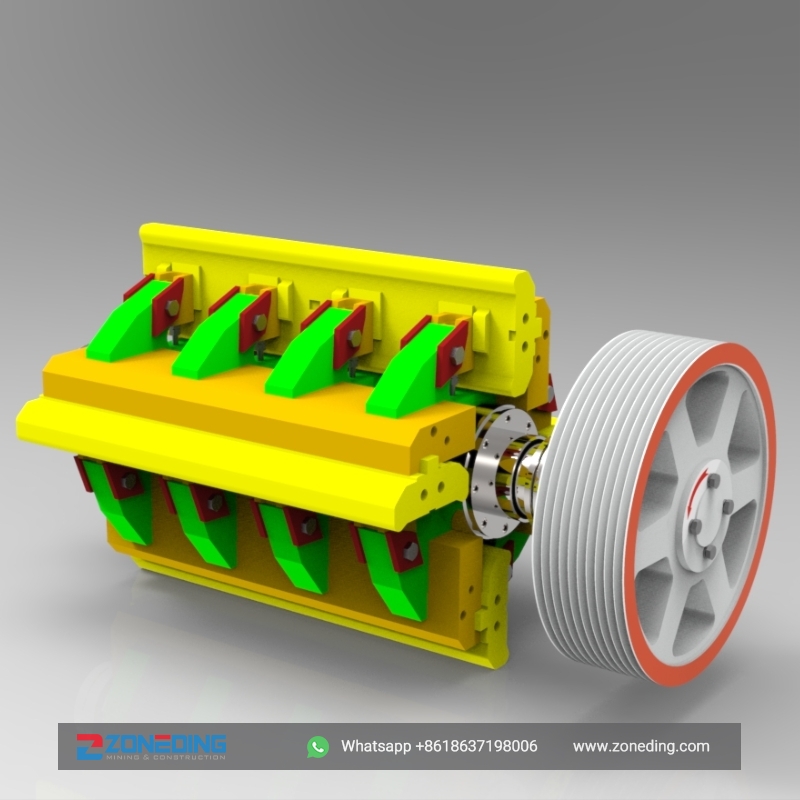

Impact Crusher Working Principle

Here is a brief overview of the working principle of an impact crusher:

- Feeding: The material to be crushed is fed into the impact crusher through a feeding inlet or hopper. This feeding process can be automated or manual, depending on the crusher model and the specific application.

- Impact Crushing: Inside the crusher, there is a rotor or hammer assembly that rotates at high speed. This rotor or hammer assembly has impact hammers or blow bars that are mounted on it. As the rotor rotates, the hammers hit the material that is falling or passing through the crusher, applying impact forces on the material. The high-speed rotation and impact forces cause the material to break into smaller pieces.

- Rebounding and Secondary Crushing: The broken pieces of material rebound from the crusher walls or anvils (if present) and collide with each other or with the hammers again, undergoing further crushing. This process of rebounding and secondary crushing continues until the material is reduced to the desired size.

- Screening and Discharge: The crushed material is then passed through a screening mechanism, which separates the material into different size fractions based on the size of the openings in the screen. The material that meets the desired size specifications is discharged from the crusher through a discharge outlet, while the oversize material is recirculated for further crushing.

- Control System: Modern impact crushers are equipped with advanced control systems that monitor and regulate various parameters such as rotor speed, feed rate, and discharge size. These control systems ensure efficient and reliable operation of the crusher.

Structural Advantages of ZDM Impact Crusher

- Heavy-duty Construction: Constructed with robust materials and components for durability in harsh crushing environments.

- Optimized Crushing Chamber: Chamber design maximizes crushing efficiency while minimizing wear.

- Adjustable Gap: Allows for adjustment of crushing gap based on material properties and output requirements.

- Ease of Maintenance: Design facilitates easy cleaning and replacement of wear parts, minimizing downtime.

- Integrated Screening System: May feature an integrated screening system for classifying crushed material to meet different size specifications.

- Advanced Control System: Advanced control system may be available to monitor and adjust key parameters for efficient and stable operation.

General Specification

Impact crusher

| Model | Specification(mm) | Feed Opening(mm) | The Maximum Feeding Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension(mm) | Total Weight(t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

Stone crushing plant process

It contains feeding, coarse crushing, medium crushing, screening, optional fine crushing, conveying, and storage and transportation of finished products. Feeding through the vibrating feeder uniform continuous feeding, coarse crushing by the jaw crusher will be crushed into small pieces of stone, crushing in the impact crusher, and then by the vibrating screen screening, does not meet the requirements of the particle size of the stone returned to the re-crushing, for the higher requirements of the particle size of the optional fine crushing links, between the links by the belt conveyor transportation stone, finished products are stored in the yard and transported as needed.

Customer site

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

Vibrating Feeder

What is Vibrating Feeder?Applications of ZDM Vibrating FeederHow Vibratory Feeder WorkAdvantages of Vibrating Feeder MachineGeneral SpecificationVibrating FeederFAQRelated Products Vibrating Feeder The vibrating feeder (vibratory feeder) is suit…

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine…

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine