High Efficiency Concentrator

High efficiency concentrator is suitable to dewater concentrate and tailings in concentrator plant.

- Applied Material:Slime, waste water, waste slag, etc

- Capacity:5.6-6250t/d

- High efficiency concentrator is suitable to dewater concentrate and tailings in concentrator plant. The high efficiency concentrator produced by our company is a machine for removing the water in the ore concentrate and the tailings in the ore beneficiation plant.

Introduction of High Efficiency Concentrator

Thickener (also known as thickener or agitator) is suitable for concentrate and tailings dehydration treatment during the beneficiation process to increase the slurry concentration from 20-30% to 40-70%. It is of great significance to improve the utilization rate of backwater, the concentration of bottom flow and protect the environment. In fact, the high efficiency concentrator is not a kind of simple sedimentation equipment, but a new type of dehydration equipment combined with the characteristics of mud layer filtration. It is divided into central transmission type, peripheral transmission type, sludge, intermittent type, vertical flow and continuous thickener.

Table of Contents

- High Efficiency Concentrator

- Introduction of High Efficiency Concentrator

- The Features of High Efficiency Concentrator

- The Structure Device of High Efficiency Concentrator

- Applications of High Efficiency Concentrator

- The Working Principle of High Efficiency Concentrator

- Customer Case

- Parameters Of High Efficiency tailings thickner / concentrator

- FAQ

- Related Products

The Features of High Efficiency Concentrator

- The flocculant is added to increase the particle size of settling solids, thus speeding up the settlement.

- The inclined plate is installed to shorten the settlement distance of ore and increase the settlement area.

- It can play a role in flocculating, filtering, compressing, and improve the treatment capacity of thick facies layer deposited by mud.

- It is equipped with complete automatic control facilities.

The Structure Device of High Efficiency Concentrator

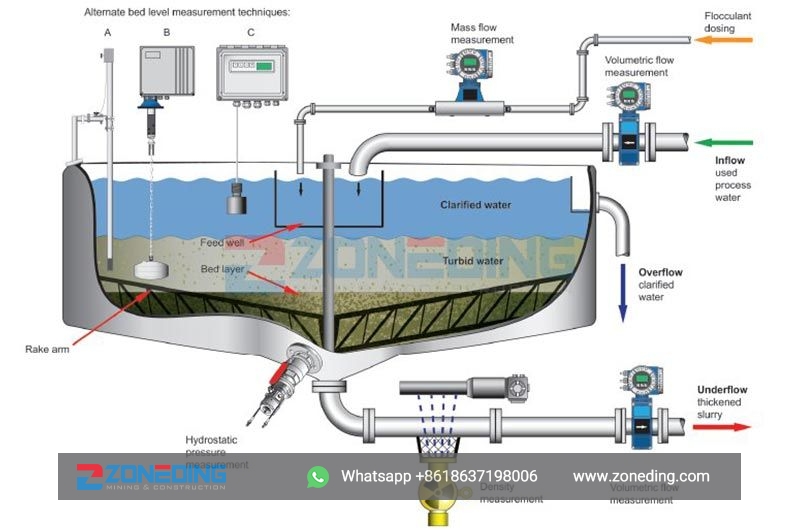

The high efficiency concentrator generally consists of the thickener pool, transmission device, lifting device, feeding device, unloading device and signal safety device. The main feature of this machine is to add a certain amount of flocculant to the pulp to be concentrated, so that the ore particles in the pulp will form flocculation groups and accelerate its settlement rate, so as to improve the concentration efficiency.

Applications of High Efficiency Concentrator

High efficiency concentrator is suitable for dehydration, concentration and treatment of tailings in concentrator factory, and widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries.

The Working Principle of High Efficiency Concentrator

The working principle of a high-efficiency concentrator involves two main aspects: increasing the size of solid particles and expanding the settlement area.

Increasing the size of solid particles in slurry and the settlement area of high-efficiency concentrator can improve the processing capacity of high-efficiency concentrator. The particle size of settling particles can be increased by adding flocculant to high-efficiency concentrator to make fine particles agglomerate. The inclined plate in the high-efficiency concentrator can increase the settlement area, shorten the settlement distance of particles and improve the concentration efficiency. The test and industrial production shows that under the same processing capacity, the diameter of the high-efficiency thickener is only two-thirds to half of the diameter of the ordinary thickener, and the area is about one-ninth to one-fourth of the ordinary thickener, while the processing capacity per unit area can be increased several times to dozens of times.

Customer Case

Parameters Of High Efficiency tailings thickner / concentrator

High Efficiency Concentrator

| Model | GW-3 | GW-5 | GW-8 | GW-10 | GW-12 | GW-20 | GW-30 | GW-40 | GW-50 |

| Filter area(m2) | 3 | 5 | 8 | 10 | 12 | 20 | 30 | 40 | - |

| Cylinder size(mm) | φ1068×1060 | φ1600×1060 | φ2000×1500 | φ2000×1750 | φ2000×2000 | φ2500×2650 | φ3350×3000 | φ3350×4000 | φ3350×5000 |

| cylinder speed(r/min) | 0.156-1.56 | 0.156-1.56 | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 | 0.14-0.54 | 0.12-0.56 | 0.12-0.56 | 0.12-0.56 |

| Vacuum pressure(KPa) | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Swept volume(m3/min.m2) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Blast pressure(Kpa) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| Blast volume(m3/min.m2) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Capacity(t/h) | 0.8-1.5 | 1.6-2.4 | 2.8-3.6 | 3-4 | 3-5 | 3-8 | 4.5-12 | 6-16 | 7.5-20 |

| Cylinder motor(kw) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 5.5 |

| Stirring motor(kw) | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 |

| Weight(kg) | 2635 | 2850 | 5455 | 6317 | 6365 | 10600 | 17200 | 19500 | 21500 |

FAQ

1.Are you a manufacturing or trading company?

We are manufacturer. Our factory established in 2004.

2.What is the after-service of your company?

We can provide the foundation drawing, installation service, training, spare parts and other service according to the customer’s requirements.

3. Which mineral processing method should I choose?

According to the properties of minerals, we will choose the treatment method that most suitable for you.

4. What machines are usually required for the whole production line?

Usually there are feeder, primary and secondary crushers, vibrating screen, ball mill, classifier, spiral chute, magnetic or flotation machine, dryer, etc. Equipment can be adjusted.

5. What is the final mineral concentration?

It depends on the ore grade. The final concentration of gold ore can reach 80-90%.

Related Products

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

Jigging Separator Machine

Jigging Machine for saleApplicationsProduct StructureWorking PrincipleParameters of Jigging MachineJigging Machine customer work siteRelated Products Jigging Machine(jig concentrator, jig machine, mineral jig, Jiggin…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine