Gypsum Briquetting Machine

Raw Materials:nGypsum, tailings, sludge, kaolin, clay, activated carbon, coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, etc.- Briquette Size:30-60mm or customerized

- Capacity: 10-35TPH

Gypsum Briquetting Machine For Sale

Gypsum briquette machine is mainly used to suppress desulfurization gypsum powder, and the pressed balls can be used as a retarder in cement plant. In recent years, its application in building material industry is very extensive. It has characteristics of high molding pressure, easy demoulding, high-efficiency, low energy consumption, low failure rate, and convenient repair. It has five types according to the yield. The direct pressing without subsequent drying process is more conducive to the existing production process of convergence and transformation, which has high forming strength. It is suitable for all kinds of transportation, so as to reduce the packaging cost.

Gypsum compactor and its supporting equipment can compress desulfurized gypsum powder into disposable ball products without any help of adhesive. Through the characteristics of high yield and good hardness, it has been put into production in many power plants and cement plants in China with good results.

Table of Contents

Features And Performance of Gypsum Briquetting Machine

Structure Features

Gypsum briquetting machine can press desulfurized gypsum powder, phosphor gypsum and natural gypsum into balls at one time without adding any binder, which has high ball forming rate, high yield, high strength, convenient transportation and storage. It has been put into use in many power plants and cement plants put into operation.

Performance Advantages

Short process, low failure rate, high-quality alloy steel material (patent) is used in the main roll to greatly improve wear and pressure resistance, so that the machine has a long service life.

Energy conservation and environmental protection, improving the utilization rate of waste and saving cost

The desulfurization gypsum ball press machine does not cause sticking after the formed gypsum is put into the grinding machine, and does not affect the output of the mill.

Compact structure, convenient maintenance, simple operation, and convenient installation.

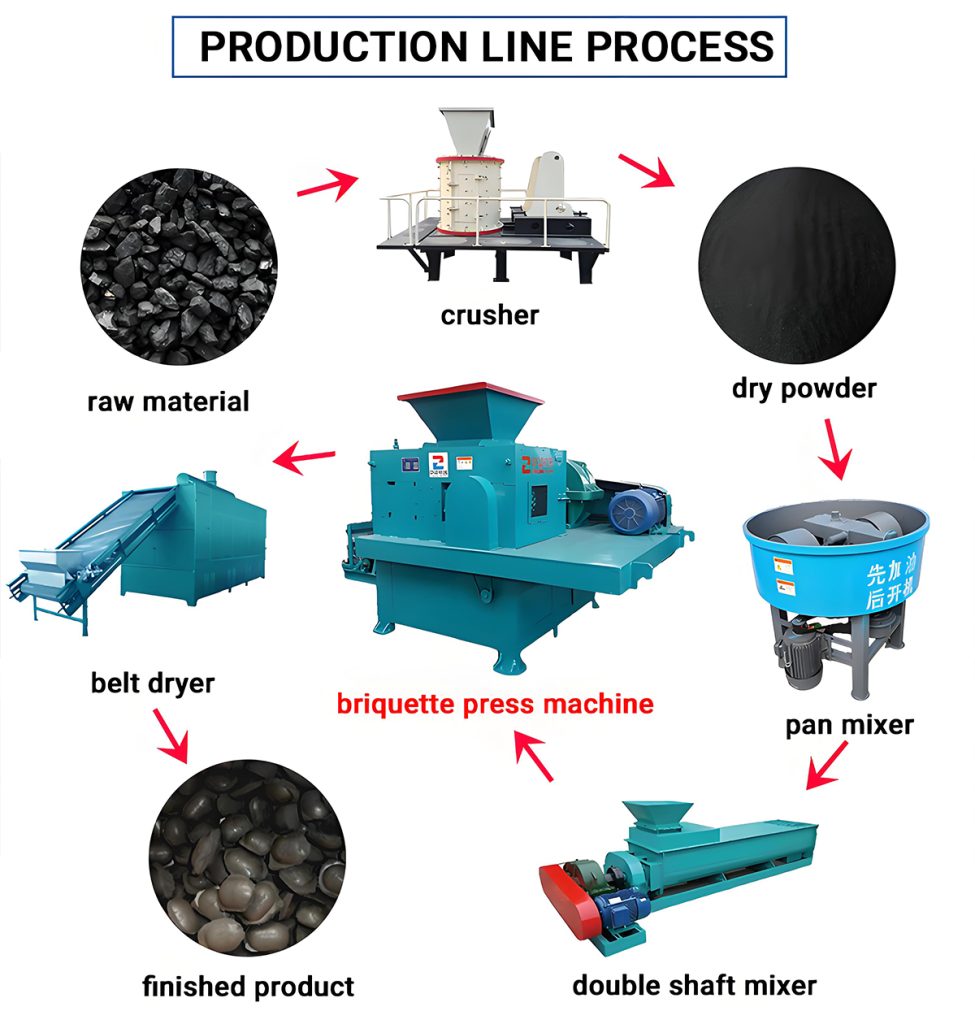

Working Principle of Gypsum Briquetting Machine

The gypsum press obtains power from the hydraulic circuit, the hydraulic control valve and the accumulator. The material enters the feeder hopper quantitatively through the storage box and then enters the space between the two rollers after the adjustment gate of the hopper is changed. When the forming pressure changes from low to high and reaches the maximum pressure at the double roller connector, the roll material is run in reverse at a constant speed. When passing through the production line, the material is in the state of ball separation, and the molding pressure is rapidly reduced, thus completing the separation process.

Final Briquettes of Gypsum Briquetting Machine

Finished Shapes of Briquetting Machine

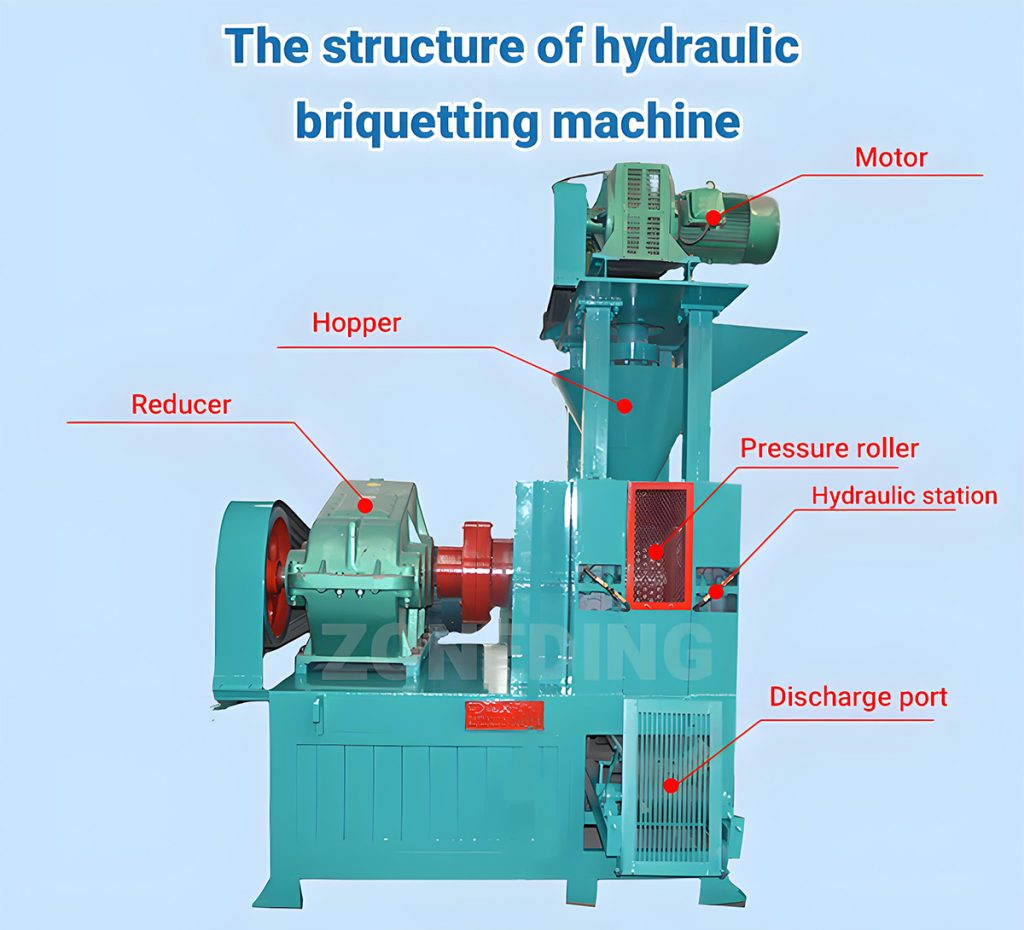

Composition of Gypsum Briquetting Machine

The gypsum briquetting machine is typically composed of two main parts: the feed part and the drive part

Customer Case

General Specification

Briquetting Machine

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Dry Powder Briquetting Machine

Dry Powder Briquetting Machine For SaleThe Dry Powder Briquetting Machine offers Several Performance AdvantagesThe Dry Powder Briquetting MachineApplicationsWorking Principle of Dry Powder Briquetting MachineCustomer CaseGeneral SpecificationBriqu…

Pulverized Coal Briquetting Machine

Pulverized Coal Briquetting Machine For SaleFunction of Pulverized Coal Briquetting MachineCharacteristics of Pulverized Coal Briquetting MachineThe Pulverized Coal Briquetting Machine Performance AdvantagesStructure CompositionHow to Identify the…

Mineral Powder Briquetting Machine

Mineral Powder Briquetting Machine For SalePerformance Features of Mineral Powder Briquetting MachineApplications of Mineral Powder Briquetting MachineStructure of Ore Powder Briquetting MachineCustomer CaseGeneral SpecificationBriquetting Machine…

Slurry Briquetting Machine

Slurry Briquetting Machine For SaleWorking Principle of Slurry Briquetting MachineApplications of Slurry Briquetting MachineCustomer CaseGeneral SpecificationBriquetting MachineFAQRelated Products Slurry refers to the semi soli…

Metal Powder Briquetting Machine

Metal Powder Briquetting Machine For SaleApplications of Metal Powder Briquetting MachineCharacteristics of Metal Powder Briquetting MachineMetal Powder Briquetting Machine Structure and CompositionOperation InstructionCustomer CaseGeneral Specifi…

Lime Briquetting Machine

Lime Briquetting Machine For SaleApplications of Lime Briquetting MachinePerformance Advantages of Lime Briquetting MachineWorking Principle of Lime Briquetting MachineOperation Guidance of Lime Briquetting MachineGeneral SpecificationBriquetting …

Aluminite Powder Briquetting Machine

Aluminite Powder Briquetting Machine For SaleApplications of Aluminite Powder Briquetting MachineHow to Turn Waste into TreasureFeatures of Aluminite Powder Briquetting MachineCustomer CaseGeneral SpecificationBriquetting MachineFAQRelated Product…

Iron Powder Briquetting Machine

Get Price And SupportIron Powder Briquetting Machine For SaleZoneding Iron Briquette Machine Classification Based on StructureStructural Features of Iron Powder Briquette MachineApplications of Iron Powder Briquette MachineRequirements of Processe…

Charcoal Briquetting Machine

What is Charcoal Briquette MachineApplications of Charcoal Briquette MachineHow Does a Charcoal Briquette Machine WorkCharcoal Briquette Size and Moisture RequestsGeneral SpecificationBriquetting MachineFAQRelated Products Ch…

Coal Briquetting Machine

Coal Briquette Machine Foe SaleApplications of Coal Briquetting MachinePerformance and Structure Advantages of Coal Briquetting MachineThe Performance AdvantagesThe Structure AdvantagesCustomer CaseGeneral SpecificationBriquetting MachineFAQRelate…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine