Gold Mine Wet Pan Mill

- Feeding Size: <25mm

- Discharging Size: 0.5-0.1mm

- Engine power:5.5-30kw

- Materials: metal minerals, non-metallic minerals, rare metals and other materialssuch as gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, etc.

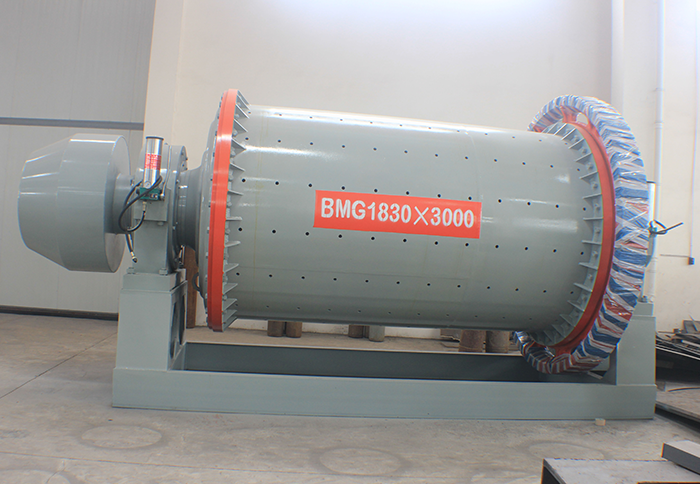

Wet Pan Mill for sale

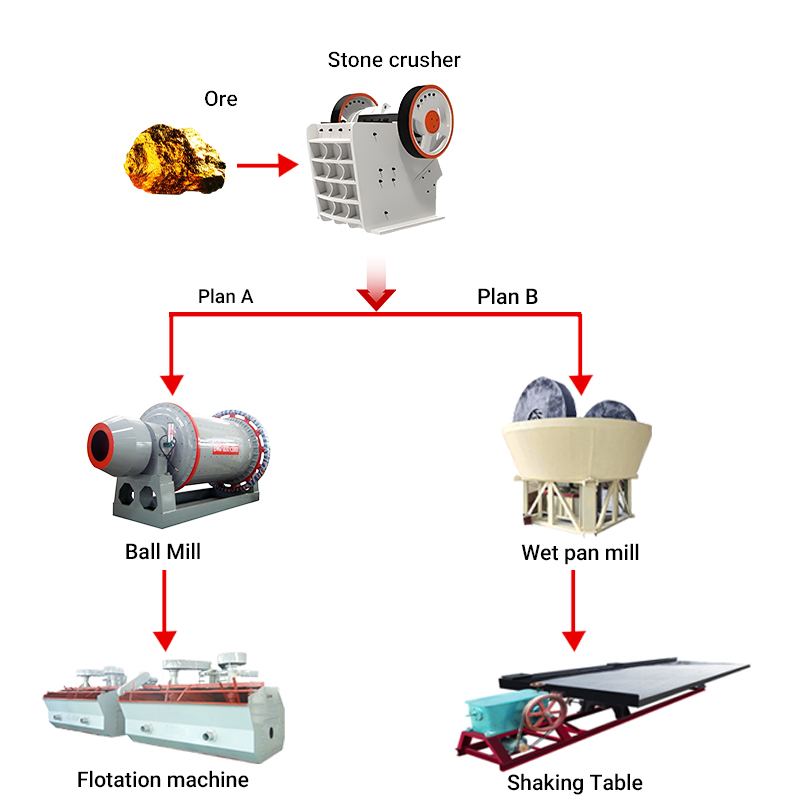

Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-operate equipment, especially suitable for gold extraction in small and medium-sized mines.

According to different structures, it is divided into double-roller and three-roller type. The most commonly used is double-roller type.

Table of Contents

Applications

Wet Pan Mill is a kind of equipment used for ore grinding, especially suitable for grinding and beneficiation of metal ores such as gold, silver, lead, zinc, molybdenum, iron, copper and antimony.

Wet Pan Mill Advantages

- Low investment: Compared with other ball mill equipment, the investment cost of wet grinding disc mill is lower.

- High output: It has high production efficiency and meets the needs of small and medium-sized mines.

- Easy to use and maintain: Simple structure, easy operation and low maintenance cost.

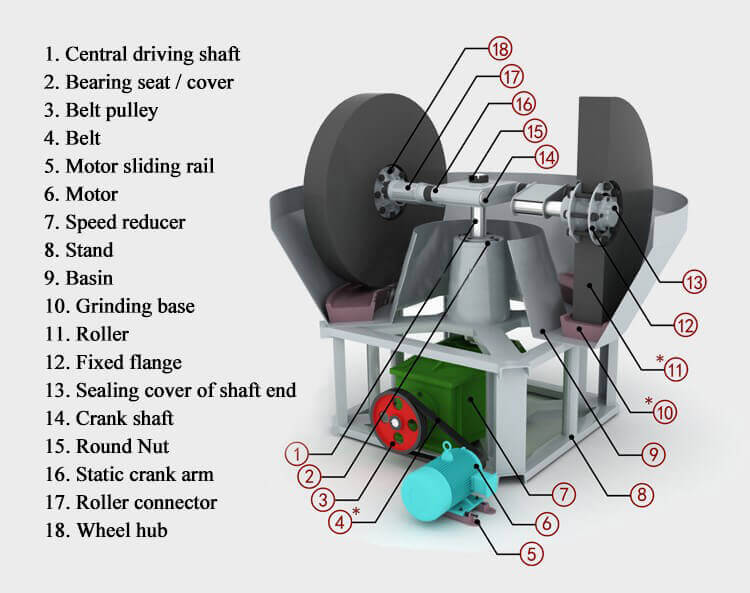

Product Structure

The main parts of the wet pan mill are the driving shaft, bearing seat, roller, speed reducer, motor, and so on.

It has small investment, high output, low productioncost, good efficiency, and easy installation.

Wet Pan Mill Working Principle

First, the motor transmits power to the reducer, then the central transmission shaft transmits it to the horizontal shaft, and finally the roller moves counterclockwise, and the materials in the mill are ground into fine particles.

While grinding the minerals,the fine particles of the dissociated minerals float to the upper surface and are discharged from the overflow discharge port; the coarse-grained minerals settle at the bottom and continue to be ground until the fineness reaches the standard.

Parameters of Wet Pan Mill

| Model | Rotate speed (r/min) | Grinding media Weight (T) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (KW) | Weight (T) |

| Φ900×1800 | 36 | 1.5 | ≦20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.5 |

| Φ900×3000 | 38 | 2.7 | ≦20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.7 |

| Φ1200×2400 | 36 | 3 | ≦25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200×3000 | 36 | 3.5 | ≦25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200×4500 | 36 | 5 | ≦25 | 0.074-0.4 | 11.6-5.8 | 55 | 13.8 |

| Φ1500×3000 | 32.4 | 7.5 | ≦25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500×4500 | 29.7 | 11 | ≦25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500×5700 | 27 | 12 | ≦25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830×3000 | 25.4 | 11 | ≦25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830×4500 | 25.4 | 15 | ≦25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830×7000 | 24.1 | 23 | ≦25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100×3000 | 23.7 | 15 | ≦25 | 0.074-0.4 | 6.5-36 | 155 | 34.8 |

| Φ2100×4500 | 23.7 | 24 | ≦25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2100×7000 | 23.7 | 26 | ≦25 | 0.074-0.4 | 8-48 | 280 | 56.6 |

| Φ2200×4500 | 21.5 | 27 | ≦25 | 0.074-0.4 | 9-45 | 280 | 51.8 |

| Φ2200×6500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200×7000 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200×7500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400×3000 | 21 | 23 | ≦25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400×4500 | 21 | 30 | ≦25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700×4000 | 20.7 | 40 | ≦25 | 0.074-0.4 | 12-80 | 380 | 94 |

| Φ2700×4500 | 20.7 | 48 | ≦25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200×4500 | 18 | 65 | ≦25 | 0.074-0.4 | 25-120 | 630 | 137 |

| Φ3600×4500 | 17 | 90 | ≦25 | 0.074-0.4 | 25-140 | 850 | 158 |

| Φ3600×6000 | 17 | 110 | ≦25 | 0.074-0.4 | 25-160 | 1250 | 175 |

| Φ3600×8500 | 18 | 131 | ≦25 | 0.074-0.4 | 45.8-256 | 1800 | 252 |

| Φ4000×5000 | 16.9 | 121 | ≦25 | 0.074-0.4 | 45-208 | 1500 | 203 |

| Φ4000×6000 | 16.9 | 146 | ≦25 | 0.074-0.4 | 65-248 | 1600 | 218 |

| Φ4000×6700 | 16.9 | 149 | ≦25 | 0.074-0.4 | 45-252 | 1800 | 238 |

| Φ4500×6400 | 15.6 | 172 | ≦25 | 0.074-0.4 | 54-306 | 2000 | 280 |

Gold Mine Wet Pan Mill is an ideal choice for gold extraction in small and medium-sized mines due to its high efficiency, energy saving and easy operation. Whether you are just starting a small-scale mining operation or looking to upgrade your existing equipment, a Gold Mine Wet Pan Mill is a worthy investment that can bring long-term profitability and sustainability to your mine.

To learn more about gold wet disc mills or explore our mining equipment range, please feel free to contact us. Let us help you improve your mine efficiency and move towards a successful future!

Related Products

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine