Fly Ash Dryer

The fly ash dryer produced by Zoneding Machinery is a rotary drying equipment used for drying materials like fly ash, phosphor gypsum, and industrial waste. It is known for its reliable operation, efficient drying, and high capacity.

- Capacity: 4-90 t/h

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source:biomass, natural gas, diesel, coal, etc.

- Application:Widely used for drying fly ash, fly, mineral materials, slag and other material.

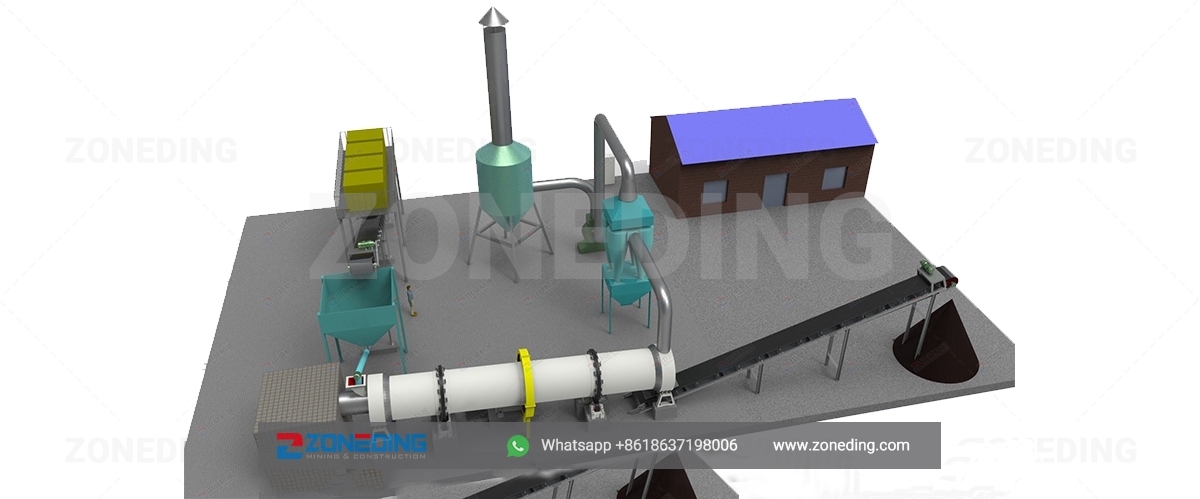

coal ash drying system

Fly ash dryer produced by Zoneding Machinery is widely used for drying fly ash, phosphor gypsum, industrial dust and waste slag. It is also known as of powdered coal ash dryer or pond ash dryer. This dryer is a type of rotary drying equipment and also plays a key part. It has numerous features such as reliable operation, excellent drying effect, high thermal efficiency and large capacity.

Besides, fly ash dryer has resolved the pollution and tough disposal problems of fly ash, which not only narrows the pollution, but also turns waste into resources and improves the economic benefit.

Applications of the Powdered Coal Ash Dryer

Adopting new type international technology, Zoneding fly ash drying equipment is widely used in the advanced utilize of cement clinker, cement mixing materials, large hydro project, pump concrete, large-volume concrete products, high-grade filler, baked brick, etc.

In addition, fly ash dryer made by Zoneding Machinery is commonly used in ore processing, building materials, metallurgy, railway, highway, and other fields for drying materials with certain humidity like ore powder, zin powder, kaolin, limestone, fly ash, phosphor gypsum, industrial dust and waste slag, etc.

Applications of Fly Ash Dryer

Advantages of Fly Ash Dryer

- Professional pertinence, which is aimed at the properties of fly ash such as high humidity, low density and large change of liquidity;

- Low investment cost with a wide range of fuel option, excellent drying effect and large capacity;

- Adjustable humidity indicators according to requirements of customers, superb configuration, smooth and reliable operation and durability;

- High economic values and solving difficulties in dealing with fly ash pollution.

Benifits of Fly Ash Dryer

How Fly Ash Dryer Works

Convection and heat conduction are mainly used in the drying process. When the hot wind in the oven gets the set temperature, the dryer works with the order from the PC system. Wet fly ash is then sent into the inner layer of the fly ash drying equipment by the feeder evenly and goes with the scorching wind. The wet material is sent spirally by the fixed shoveling plate.

Next, the material moves to another end of the oven and into the middle layer. This time, wet ash moves forward against the wind stepping back in two steps. Here in the intermediate layer, heat from the inner layer and the middle layer is fully utilized, thus the drying efficiency is improved to the best situation.

Lastly, dried fly ash gets to the other end of the intermediate layer and into the outer layer moving in rectangular and multi-loop mode. Fly ash that is dried to satisfactory is blown out of the dryer with the effect of the hot wind. The other will move more slowly on its weight and be dried one more time in the outer layer to required humidity.

Working Principle of Fly Ash Dryer

Environmental Protection Values of Coal Ash Dryer

In coal-fired boiler of the power plant system, the emission of coal ash can be divided into 2 types, dry emission, and wet emission. As a kind of favorite resources, dry coal ash is of great economic value; wet emission will cause certain pollution to the environment. Processing of moist coal ash has grown up to be an urgent problem at present.

Fly Ash Dryer recycles the burnt coal powder and dries it into fly ash that can be used in concrete and other fields. It is an energy-saving process. This dryer and the collector equipped collecting the ash avoiding it getting into the air or the rivers, which is environmental protection. Compared to the traditional dryer, this new type Fly Ash Dryer gives a maximum utilization of the heat. Efficiency is upgraded and fuel is saved.

Value of Fly Ash Dryer

Fly ash is mixed material produced by coal powder when it is burned at high temperature (some like volcanic ash). Coal powder is milled into particle less than 100 micrometers and is burnt into high temperature smoke mixed with lots of incombustible matter. With the dust collecting system, we go to get the fly ash. Environmental pollution and energy waste are aroused if fly ash is not utilized rationally. For the recycling, the Fly Ash Dryer is born.

Dried fly ash can be used to make cement clinker, baked brick, aerated concrete and hollow brick for the construction of roads and dams. In addition, the floating beads, microbeads, powdered iron, carbon and aluminum can be selected from fly ash to make other materials.

Applications of Fly Ash

General Specification

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine