Fluorite Processing

Fluorspar, also known as fluorite, is primarily composed of calcium fluoride (CaF2) and finds widespread industrial use as a source of fluorine. The sorting of fluorite ore is achieved through gravity separation and flotation techniques. The design and equipment of a fluorspar beneficiation plant will be tailored to the specific characteristics of the fluorite ore, including factors such as ore type, embedded particle size, and ore properties. We customize the design and equipment selection in accordance with these factors and the specific requirements of the situation at hand.

If you are interested in our products, please email us at zd-machine@kssb.cn

Related notes

What is a Ball Mill Used For?

How to choose magnesium ore ball mill? The role and advantages of magnesium ore ball mill

Iron Fine Powder Ball Mill Application Scope

Phosphate ball mill working principle, structure, phosphate ball mill steel ball loading capacity

Should I use a ball mill or a rod mill to grind limestone?

Lithium pyroxene ball mill features, lithium ore ball mill price

loading…

已经是到最后一篇内容了!

Related Products

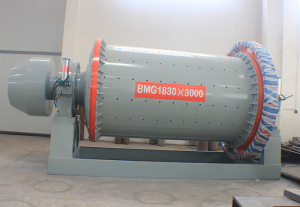

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

Jigging Separator Machine

Jigging Machine for saleApplicationsProduct StructureWorking PrincipleParameters of Jigging MachineJigging Machine customer work siteRelated Products Jigging Machine(jig concentrator, jig machine, mineral jig, Jiggin…

loading…

已经是到最后一篇内容了!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it.

OK

Privacy Policy

Zoneding Machine

Zoneding Machine