Fluorite ball mills are widely used in fluorite beneficiation projects to grind fluorite ore into powder, meeting the required specifications for various applications. Fluorite is an important mineral resource used in industries such as metallurgy, ceramics, glass, cement, aluminum refining, chemical industry, and optical materials. The fluorite ball mill plays a crucial role in achieving the desired grinding results.

For example, let’s consider two fluorite beneficiation projects to highlight the selection of ball mill models:

1. In a 700t/d fluorite beneficiation project, two grinding processes are used. A lattice-type ball mill is employed as the first stage grinding equipment, and an overflow-type ball mill is used in the second stage. The grinding process achieves a fineness of -200 mesh 70.6%. The coarse concentrate is then returned to the overflow ball mill for regrinding, resulting in a product fineness of -200 mesh 95%. This project has achieved satisfactory grinding results.

2. In a 400t/d fluorite beneficiation project, a two-section one closed-circuit crushing and grinding process is employed. A lattice-type ball mill and a spiral classifier are used for grinding and classifying operations. The final grinding fineness achieved is -200 mesh, accounting for 65% of the product. This project also demonstrates effective grinding performance.

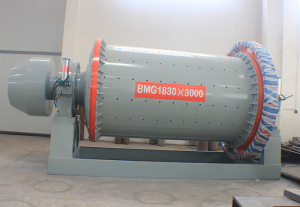

The choice of ball mill models is crucial in achieving good sorting results and obtaining qualified concentrate. Zoneding Mining and Equipment, for instance, specializes in producing high-quality ball mill equipment. With over 20 years of experience, Zoneding has delivered thousands of ball mills to various fluorite ore beneficiation plants. If you require further assistance, please feel free to contact us.

Zoneding Machine

Zoneding Machine