Flotation Machine

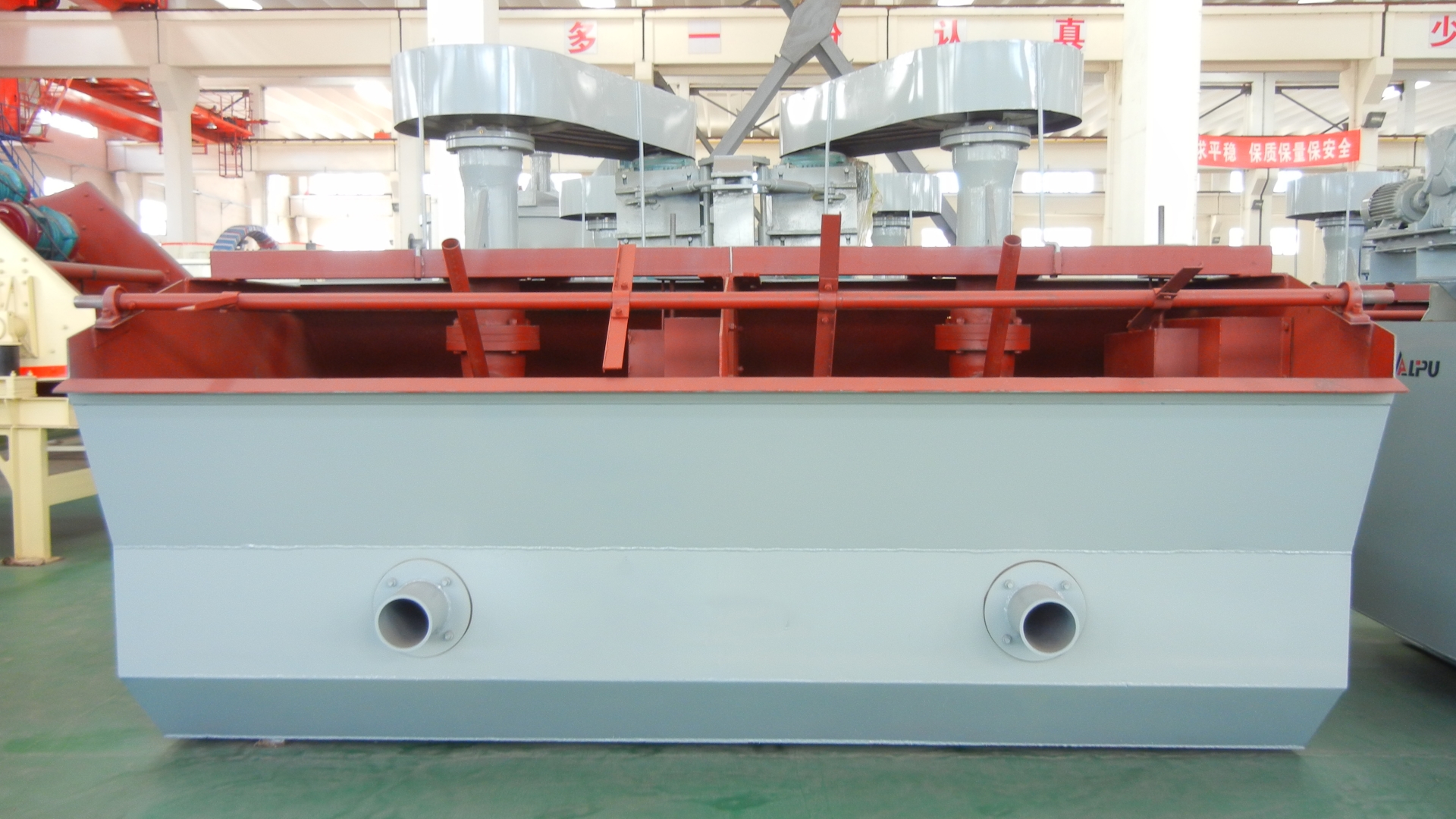

Flotation Machine For Sale

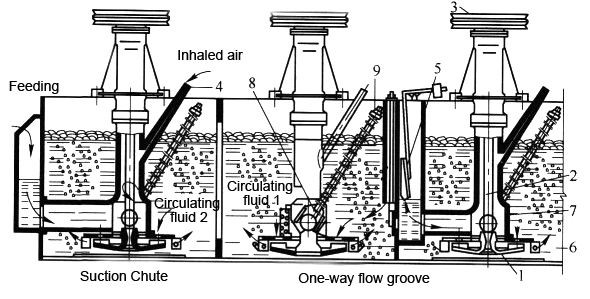

Flotation machine is mainly used for separating gold, silver, copper, iron, lead, zinc, molybdenum, nickel, aluminum and other metal minerals. It can also be used for the separation of ferrous metals and non-metals. The machine is driven by the motor triangle belt drive impeller rotation, resulting in centrifugal action to form a negative pressure on the one hand, inhale sufficient air and slurry mixing, on the one hand, stirring the slurry into a mixture of drugs, and at the same time refining the foam, so that the mineral bonding foam above the surface of the slurry to float to the surface of the formation of mineralized foam again. Adjust the height of the gate to control the liquid level, so that the useful foam is scraped out by the scraper.

Table of Contents

- Flotation Machine For Sale

- Advantages of Flotation Machine

- Flotation Machine: Suitable Ore Types

- Structure of flotation machine

- Principle of Flotation Machine

- Flotation Process

- Parameters of Flotation Machine

- Assembly site of flotation machine

- Flotation machine delivery Philippines

- FAQ

- Related Products

Advantages of Flotation Machine

- High-efficiency Separation: Unique impeller and stator design generates strong slurry circulation and fine air bubbles, realizing high-efficiency separation of minerals.

- Energy saving and environmental protection: optimized mechanical structure and electrical control system reduce energy consumption and environmental impact.

- Easy maintenance: modularized design, key components are easy to replace, reducing downtime and improving production efficiency.

- Widely used: suitable for flotation of many kinds of minerals, such as gold ore, copper ore, iron ore, etc., to meet the needs of different customers.

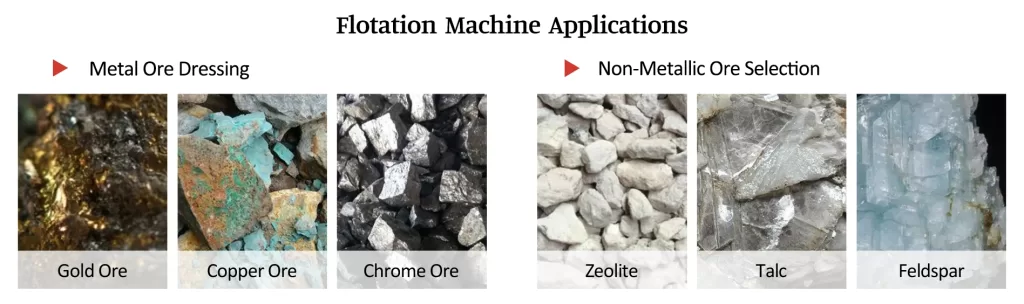

Flotation Machine: Suitable Ore Types

- Metallic ores: such as copper, lead-zinc, iron, manganese, tin, tungsten, chromium, silver, and gold ores.

- Non-metallic ores: including phosphorus, limestone, sulfur, gypsum, fluorite, talc, bentonite, and wollastonite.

- Non-ferrous metallic ores: nickel, cobalt, antimony, aluminum, lithium, and vanadium ores, among others.

It’s important to note that different ore types may exhibit varying flotation properties during the process, such as density, specific gravity, surface characteristics, and reagent reactions. Therefore, flotation machines require parameter adjustments based on the ore’s unique characteristics and beneficiation requirements to achieve optimal separation results.

Additionally, with a wide range of flotation machine models and types available, selecting the most suitable one depends on factors like ore properties, processing capacity, and beneficiation needs.

In summary, flotation machines play a crucial role in the effective extraction and utilization of mineral resources, finding widespread applications in the flotation of various metallic, non-metallic, and non-ferrous ores.

Structure of flotation machine

Flotation machine is mainly composed of impeller, cover plate, vertical shaft, inlet pipe, bearings, belts and other accessories, the wear parts of the equipment are selected from international new wear-resistant and pressure-resistant raw materials, which reduces the wear and tear and prolongs the service life of the equipment.

Principle of Flotation Machine

In the flotation machine, after adding the pharmaceutical treatment of the slurry, through the agitation of the inflatable, so that some of the mineral particles selectively fixed on top of the air bubbles; floated to the surface of the slurry is scraped to form a foam product, and the rest of the slurry is retained in the slurry, in order to achieve the purpose of separating the minerals. There are many structural forms of flotation machine, the more commonly used is the mechanical agitation flotation machine.

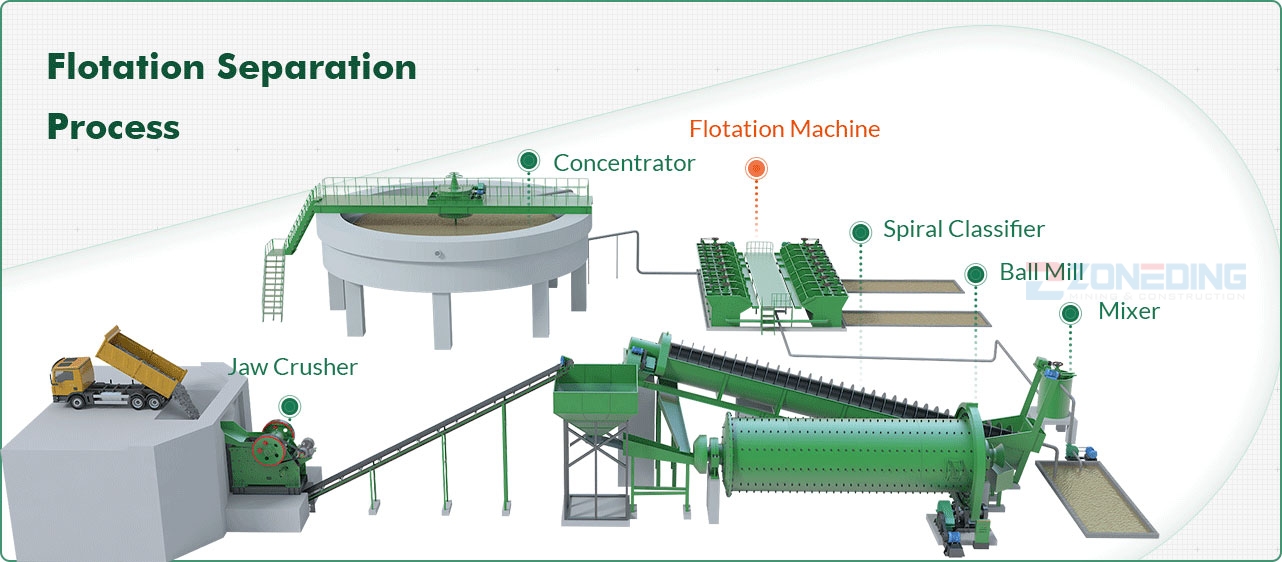

Flotation Process

Flotation process refers to the method used in the flotation process of a mineral. Flotation is the same as other mineral processing methods, to do a good job of material preparation before selection, that is, the ore should be milled and graded to achieve the concentration of fineness suitable for flotation. In addition, flotation has the following basic operations: slurry adjustment and add flotation chemicals, change the mineral wettability so that mineral particles attached to the bubble. Mineralization of bubbles. Selective attachment of mineral particles to air bubbles is the basic behavior of the flotation process. Flotation is a beneficiation method based on the different wettability of minerals by water. Generally, the nature of minerals easy to float and difficult to float is called the floatability of minerals. Flotation is the use of the difference in the floatability of minerals to separate minerals.

Parameters of Flotation Machine

flotation machine

| Category | Specification Model | Effective cubage (m) | Processing capacity (m/min) | Main shaft loam board | Dimensions (m) | Single trough Weight (t) | |||

| Power (kw) | Rotate Speed (r/min) | Rotate Speed(r/min) | Power (kw) | ||||||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7x0.7x0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90x0.82x0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75x1.6x1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2x2.2x1.2 | 3.6 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7x0.7x0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9x0.82x0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1x1.1x1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75x1.6x1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85x2.05x1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2x2.9x1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85x3.8x2 | 9.9 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4x1.4x1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6x2.15x1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2x2.9x1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85x3.8x1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9x3.8x2.0 | 10.5 | |

Assembly site of flotation machine

Flotation machine delivery Philippines

FAQ

1.Are you a manufacturing or trading company?

We are manufacturer. Our factory established in 2004.

2.What is the after-service of your company?

We can provide the foundation drawing, installation service, training, spare parts and other service according to the customer’s requirements.

3. Which mineral processing method should I choose?

According to the properties of minerals, we will choose the treatment method that most suitable for you.

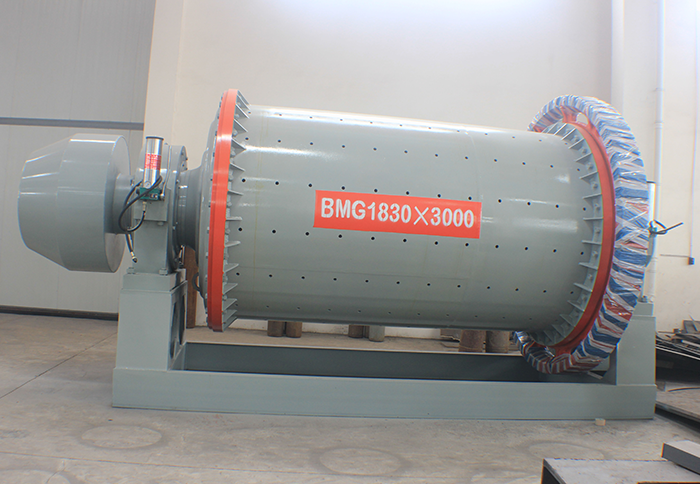

4. What machines are usually required for the whole production line?

Usually there are feeder, primary and secondary crushers, vibrating screen, ball mill, classifier, spiral chute, magnetic or flotation machine, dryer, etc. Equipment can be adjusted.

5. What is the final mineral concentration?

It depends on the ore grade. The final concentration of gold ore can reach 80-90%.

Zoneding Machine

Zoneding Machine