Fine Crusher

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages.

Applications of ZDM Fine Crusher

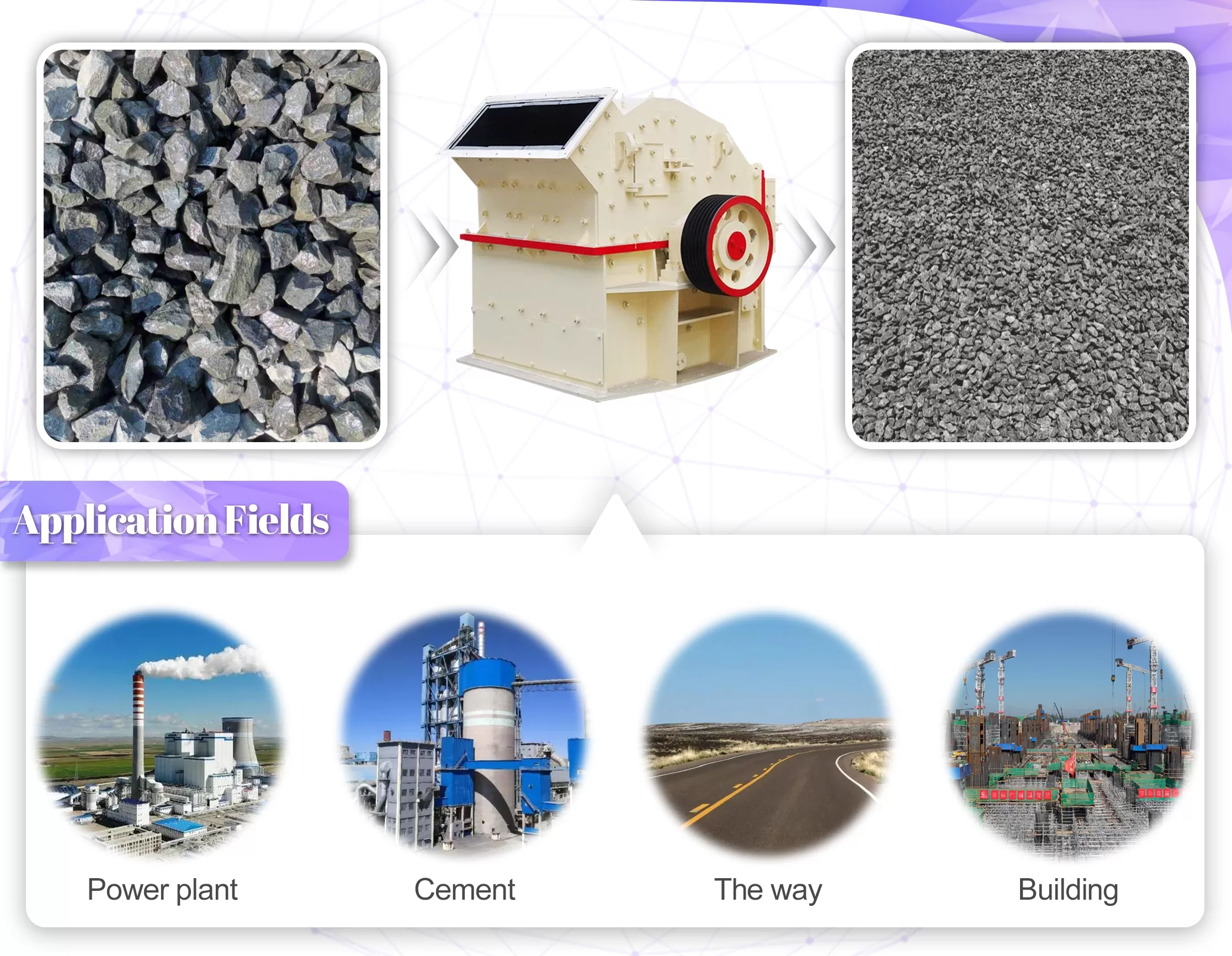

The fine crusher is mainly suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of the ball mill by 50%.

It is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

Application of Fine Crusher

The Fine Crusher Advantages

1.High crushing efficiency. The use of grate plate, rigid hard extrusion crushing and solid rotor body greatly improve the crushing efficiency.

2.Good crushing effect. The fine crusher can arbitrarily control the discharging size of materials, so the required material size can reach more than 95% and ideal material size control and classification can be realized.

3.Small wear parts wearing. Compared with hammer crushers and impact crushers, it only wears the hammerhead, while the wheel core and hammer frame have no wear.

4.Simple installation. It is light in weight, diverse in installation (removable installation) and easy to operate.

5.Convenient maintenance. It only needs to lift the upper case and open the lowercase during maintenance. A person can complete a comprehensive inspection and maintenance of the whole machine within 20 minutes with a wrench.

6.Timely discharging. Three discharging channels are adopted to discharge qualified materials in time.

7.Adjustable discharging. The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends.

Structure of the Fine Crusher

The fine crusher is mainly composed of the rotary part, guard plate and box part.

Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part. The hammer head, whose width is larger than the hammer carrier and the wheel hub, is fixed on the hammer carrier. The wheel core is composed of several wheel hubs, which are fixed on the main shaft. The two ends of the main shaft are supported on the frame with rolling bearing seats.

Comparison of Materials before Crushing and After Crushing by Tertiary Crusher

Working Principle of Fine Crusher

Once the crushing process is complete, the crushed materials are expelled or belched out of the machine.

Fine Crusher in Factory

General Specification

Fine crusher

| PXJ tertiary impact crusher | Rotorø×Width (mm) | |||||||

| Specification | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Feed opening size(mm) | 400×185 | 500×250 | 550×300 | 1000×350 | 1200×450 | 1500 | 1600×550 | 1800×800 |

| Feeding size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharging size (mm) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Adjustable range of discharge opening (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement Clinker(t/h) | 10-30 | 1040 | 20-45 | 25-55 | 35-90 | 50-150 | 85-210 | 125-270 |

| Limestone(t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-110 | 50-150 | 95-260 | 140-310 |

| Power(kw) | 4P 37KW | 4P 45KW | 4P 45KW | 4P 55KW | 6P 110KW | 6P 160KW | 4P 250KW | 4P 315KW |

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Vibrating Feeder

What is Vibrating Feeder?Applications of ZDM Vibrating FeederHow Vibratory Feeder WorkAdvantages of Vibrating Feeder MachineGeneral SpecificationVibrating FeederFAQRelated Products Vibrating Feeder The vibrating feeder (vibratory feeder) is suit…

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine…

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine