Drum Dryer

Drum dryers, including single drum dryers, have strong material adaptability and are widely used in various industries, offering advantages like simple operation, dust prevention, sealing, and maintenance, and can be configured as standalone units or complete systems.

- Capacity: 20-400 t/d

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source:biomass, steam, natural gas, diesel, etc.

- Application:Widely used for drying organic fertilizer, compound fertilizer, dregs and other powder, small particle, non sticking property and weak bond material.

What is Drum Dryer?

Drum Dryer or Single Drum Dryer is of strong adaptability to kind of materials. This equipment is the most commonly used drying equipment in cement plant for drying limestone, clay, coal powder and mixed materials and widely used in metallurgy, mining, electricity, chemical industry, and other sectors. As key equipment, drum dryer is known for its advantages such as simple and reliable operation, excellent dust prevention, good sealing effect, and convenient maintenance. Besides, this equipment can be set up as an independent unit as well as a complete system which is including dust collector, feeder, conveyor and other necessary machines.

Applications of Single Drum Dryer

>>Slag, clay, bentonite, limestone, sand, silica sand, quartz sand, kaolin, etc. in building material industry;

>>Ore, metal powder, diatomite, Coal slime, coal, mixed fine coal, etc. in coal industry, chemical industry, mining, metallurgy and other industries;

>>Organic compound fertilizer, sludge, organic fertilizer, inorganic fertilizer, etc. in the fertilizer industry;

>>Other moist powder and granular materials of special requirements like all kinds of crystal, light calcium carbonate, active white earth, magnetic powder, graphite, inorganic mud, argil, lime slurry, mineral mud, phosphorus slag, red mud in aluminum plant, etc.

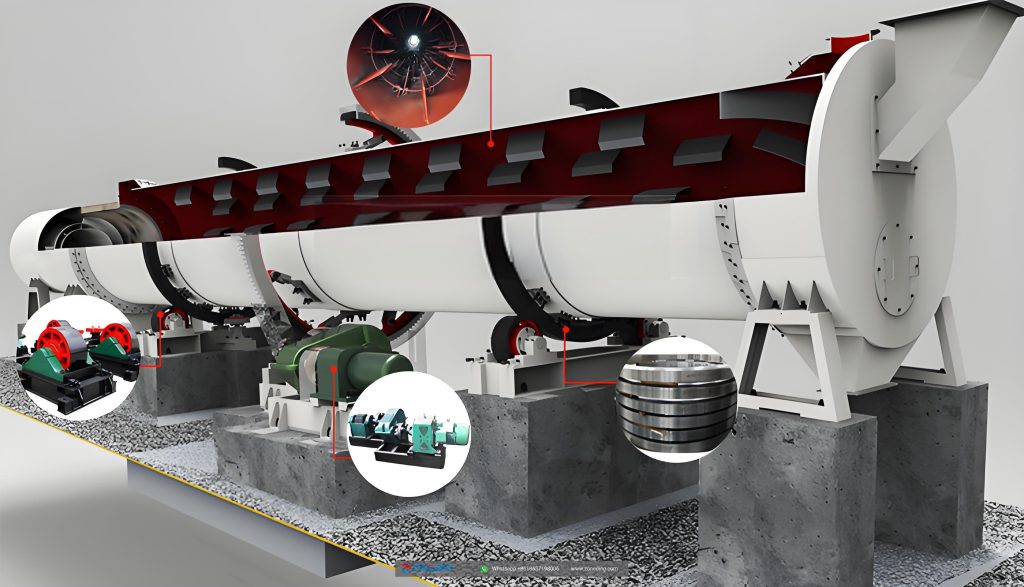

Structure and Advantageous Functions of the Drum Dryer

With the working principle of heat transfer and effect of the gravity, Drum Dryer is mainly composite with the drum, the lifting plate, the dryer roller, and the feeding box. The drum is set at a certain angle of the processing of the materials. The plates lift the wet powder or particles up and down so that the heat transfer is accomplished. The roller is the force for the drum to whirl around in order that the materials can get enough the heat of the inner wall. ZonedingDrum Dryer is of the following advantages:

- Adapt to a variety of materials drying operation, can reasonably adjust machine parameters depending on different material humidity and nature, more targeted and higher drying quality.

- Concurrent drying, heating medium and wet materials high temperature in and low temperature out; highly efficient and reasonable.

- High-temperature resistance, fast drying, less fuel consumption, and low drying cost.

- After drying, the moisture content of coal slime is lower than 8% and the granularity under 8mm.

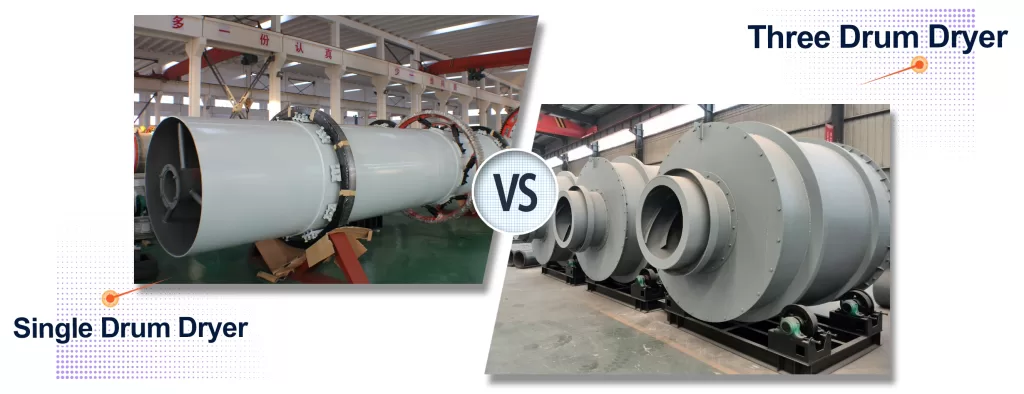

Difference Between Single Drum Dryer and Three Drum Dryer

| Single Drum Dryer | Three Drum Dryer | |

| Diameter of Outer Cylinder(m) | 1.2-3.6 | 2.5-3.6 |

| Length(m) | 8.0-28.0 | 7.0-8.0 |

| Volume(m³) | 9.0-285.0 | 16.63-81.38 |

| Capacity(T/H) | 1.9-76.0 | Yellow Sand:25-70 Slag: 20-65 |

There are types of drum dryer like single drum dryer, double drum one, three-drum one, and air-flow dryer, etc. Two of mostly used drying machines are compared here. Hope it arises a little help. From this table, it is clear that:

1> Three Drum Dryer takes less space but a better utilization of the heat;

2> Three Drum Dryer is of lower energy consumption than a single drum dryer when they take the same space;

3> Single Drum Dryer is of larger capacity and lower price;

4> Single Drum Dryer is easier operated and maintained.

Attention Needed When Operating a Single Cylinder Dryer

- Pay attention to the burning system, sir-blower fan, and the dust collector, because the efficiency of the machine mainly depends on the operation of the burning system;

- Light the oven 1 hour before the work of the dryer and give a careful check to all the attached equipment;

- Turn on the Drum Dryer Equipment in this order: the motor, the wet materials conveyor and the dry materials conveyor, which is a constant and even process;

- Control the temperature of each bearing under 50℃ when the dryer is working. Besides, keep the wheels, the cylinder and other rolling parts rotate stably and normally.

General Specification

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

Customer Site

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Ore Powder Dryer

What is Ore Powder Dryer?Applications of Ore Powder Dryer MachineAdvantages of Zoneding Ore Powder Drying MachineWorking Principle of Ore Powder DryerHow to Maintain Ore Powder DryerGeneral SpecificationFAQRelated Products Ore Powder Dryer The o…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine