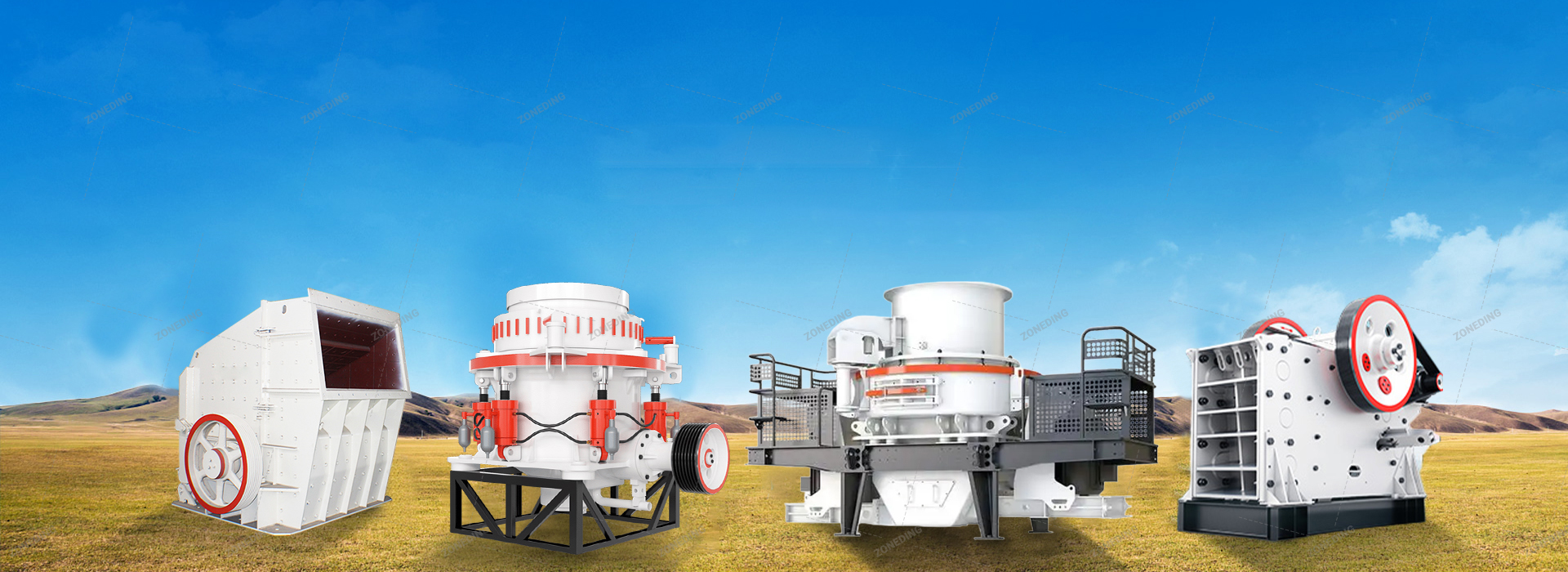

Different Types of Stone Crusher

ZONEDING offers a comprehensive range of crushers, including cone crushers, jaw crushers, impact crushers, vertical shaft impact crushers. These machines are extensively used for primary, secondary, and tertiary hard-rock crushing in stone-processing plants and sand-making facilities.

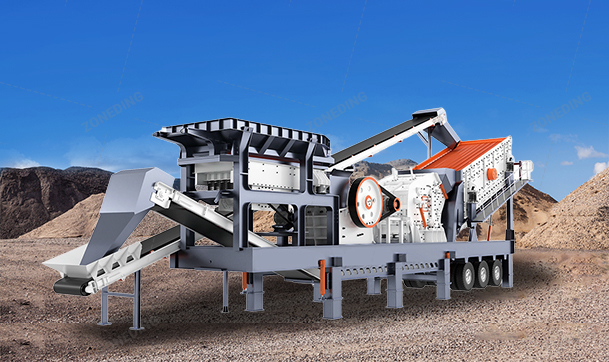

Types of Mobile Stone Crusher

Mobile Stone crushers include crawler-type mobile crusher and wheeled mobile crusher. The mobile crushing equipment is a set of movable crushing and screening equipment. According to the crushing and screening requirements, there are different combinations to meet the different needs of customers, such as mobile jaw crusher, mobile cone crusher, mobile impact crusher etc. The mobile Stone crusher eliminates the cumbersome steel frame structure and foundation construction during the crushing, saving the construction time and cost of the foundation. The mobile stone crusher can directly enter the crushing site for on-site crushing, which reduces the transportation cost of materials, and also avoids the dust pollution generated during transportation.

Wheeled mobile crusher or wheeled crushing plant, can be freely moved with the mining process. The most prominent feature of the portable crusher is the use of vehicle traction, which can be flexibly moved from one location to another.

- Applied Materials: river pebbles, rocks limestone, granite, basalt, diabase, andesite, etc., ore tailings.

- Feed Size:≤800mm

- Motor Power:37-400KW

- Capacity:85-650t/h

Crawler type mobile crushing plantr is a mobile machine equipped with a crawler-driven chassis. The equipment required for the production line can be reasonably mounted on a crawler moving frame.

- Crawler mobile impact crusher are designed for primary, secondary or tertiary crushing of construction materials in demolition/recycling/quarry & mining applications and feature extra thick heavy duty blow bars for longer life and utilization.

- Feeding Size:300-700mm

- Capacity:85-650t/h

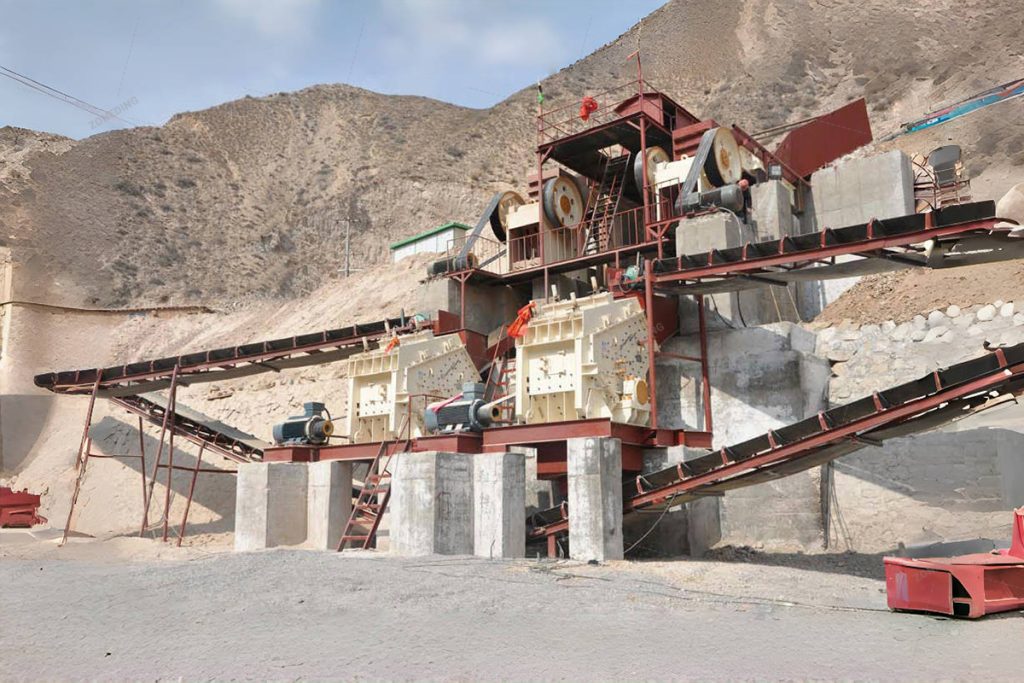

Different Combination of Stone Crusher

ZONEDING’s stone crusher can be applied to a variety of aggregate production lines, such as stones of different hardness, different productivity, different output sizes, etc. ZONEDING has provided our customers with customized aggregate production lines to produce high-quality aggregates. If you plan to invest in a crushing line, or plan to transform your existing production line, please contact us.

Crushing Flow

Related Equipment

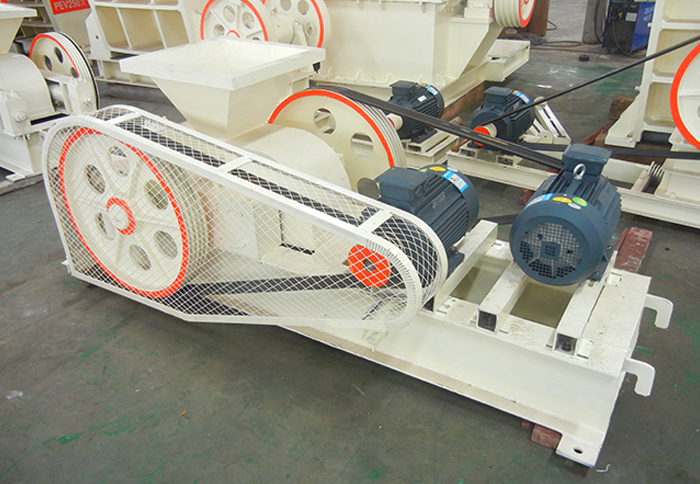

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu...

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr...

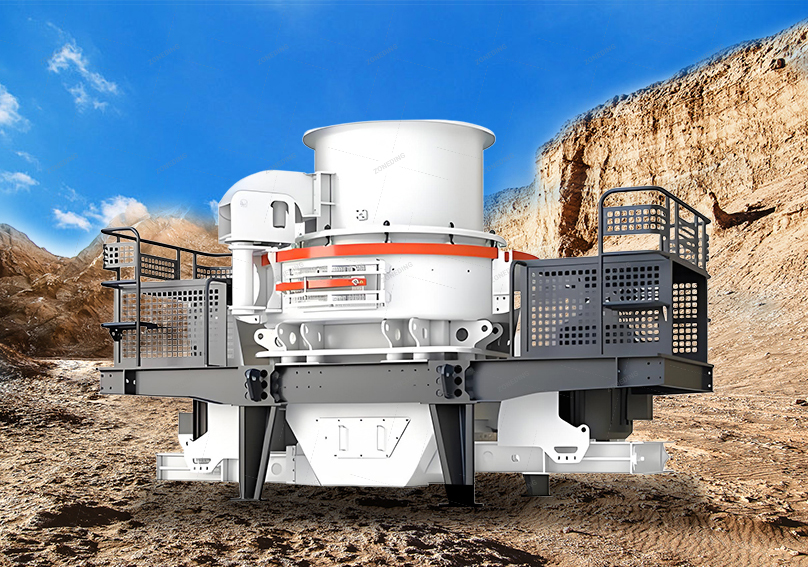

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san...

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing...

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products ...

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe...

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment ...

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts...

Vibrating Feeder

What is Vibrating Feeder?Applications of ZDM Vibrating FeederHow Vibratory Feeder WorkAdvantages of Vibrating Feeder MachineGeneral SpecificationVibrating FeederFAQRelated Products Vibrating Feeder The vibrating feeder (vibratory feeder) is suit...

Sand Washing Machine

Sand washing machine for saleIntroduction to Sand Washing MachineThe Structure of theSand WasherSand Washing Machine Working PrincipleApplications of Zoneding Sand WasherAll Kinds of Sand washing machineTechnical ParameterSand Washing Machine...

Vibrating Screen

What is Vibrating Screen?Working principle of vibrating screenClassification of Vibrating ScreenApplications of Zoneding Vibrating ScreenGeneral SpecificationVibrating ScreenCustomer SiteFAQRelated Products Vibrating Screen Vibrating Screen char...

loading...

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine