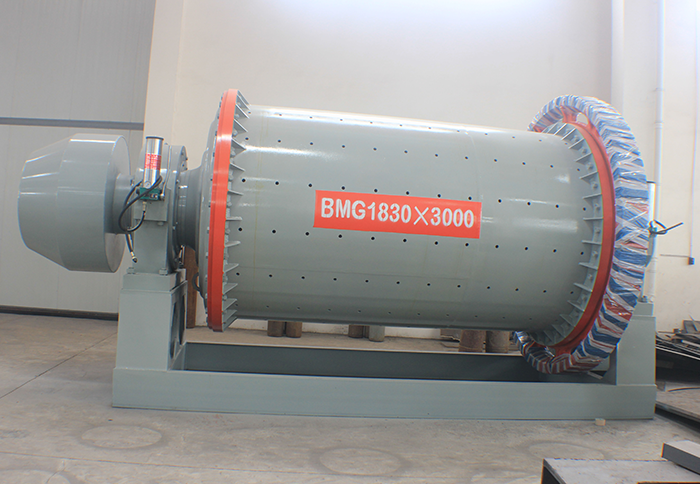

Ceramic Ball Mill

Ceramic ball mill For Sale

Ceramic ball mill, as a grinding tool for modern refinement industry, stands out in many industries with its unique material and efficient grinding performance. The machine adopts high-quality ceramic material to make grinding media, which ensures stable grinding effect in high-speed operation and avoids metal contamination at the same time, which is the first choice of equipment for pursuing high purity grinding effect.

Table of Contents

Advantages of Ceramic ball mill

- High purity grinding: using ceramic balls as grinding media effectively avoids the pollution of metal ions on the materials, ensuring the high purity of the materials after grinding.

- High-efficiency grinding: optimized structural design makes the ceramic balls form a reasonable movement trajectory inside the mill, which improves the grinding efficiency and shortens the processing time.

- Energy saving and environmental protection: adopting advanced energy-saving technology to reduce energy consumption, and low noise design to create a comfortable working environment.

- Easy maintenance: simple structure design makes the daily maintenance and upkeep of the equipment simple and easy.

- Widely used: suitable for ceramics, chemical, pharmaceutical, food and many other industries to meet the grinding needs of different materials.

Functional Advantages of Ceramic ball mill

- Fine grinding: able to grind materials to micron level to meet the demand for high precision products.

- Continuous operation: the equipment runs stably and can work continuously for a long time to improve production efficiency.

- Easy to operate: Humanized operating system design makes it easy for operators to get started and reduces training costs.

Application Scenarios of Ceramic ball mill

Whether it is glaze preparation in the ceramic industry, powder mixing in the chemical industry, or drug grinding in the pharmaceutical industry, the ceramic ball mill can meet your grinding needs with its excellent performance. It is widely used in various scenarios that require high purity and high precision grinding, and is a powerful assistant to improve product quality and productivity.

Ceramic ball mill shipment

If you are interested in this, please contact us as soon as possible! We will provide you with more than 2 solutions for you to choose from.

Ceramic ball mill customer work site

Parameters of Ceramic ball mill

Ceramic ball mill

| Model | Feeding capacity (t/time) | Shell rotation speed (r/min) | Reference motor (kw) | Liner material |

| 600×700 | 0.05 | 50 | 2.2 | Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

| 800×600 | 0.075 | 42 | 3 | |

| 900×1200 | 0.2 | 38.5 | 5.5 | |

| 1300×1500 | 0.5 | 33 | 7.5 | |

| 1500×1800 | 1.2 | 28.5 | 11 | |

| 1800×2000 | 1.5 | 24 | 15 | |

| 2600×2800 | 5 | 16.5 | 37 | |

| 3000×3800 | 10 | 14.5 | 57.2 | |

| 3200×4600 | 15 | 13.5 | 75 |

FAQ

1.Are you a manufacturing or trading company?

We are manufacturer. Our factory established in 2004.

2.What is the after-service of your company?

We can provide the foundation drawing, installation service, training, spare parts and other service according to the customer’s requirements.

3. Which mineral processing method should I choose?

According to the properties of minerals, we will choose the treatment method that most suitable for you.

4. What machines are usually required for the whole production line?

Usually there are feeder, primary and secondary crushers, vibrating screen, ball mill, classifier, spiral chute, magnetic or flotation machine, dryer, etc. Equipment can be adjusted.

5. What is the final mineral concentration?

It depends on the ore grade. The final concentration of gold ore can reach 80-90%.

Related Products

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine