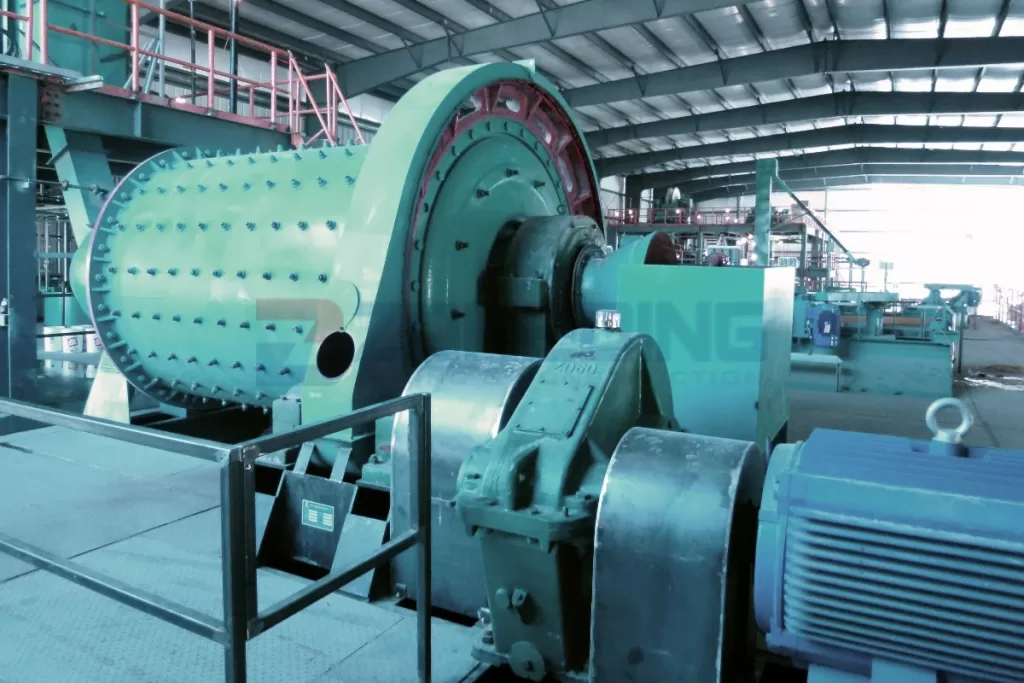

Ball Mill

- Feeding Size: <25mm

- Discharging Size: 0.075-0.4mm

- Capacity: 0.65-615t/h

- Materials: Gold ore, iron ore, copper ore, manganese ore, rock phosphate,limestone, cement clinker, potassium feldspar, quartz, coal, ceramics, etc.

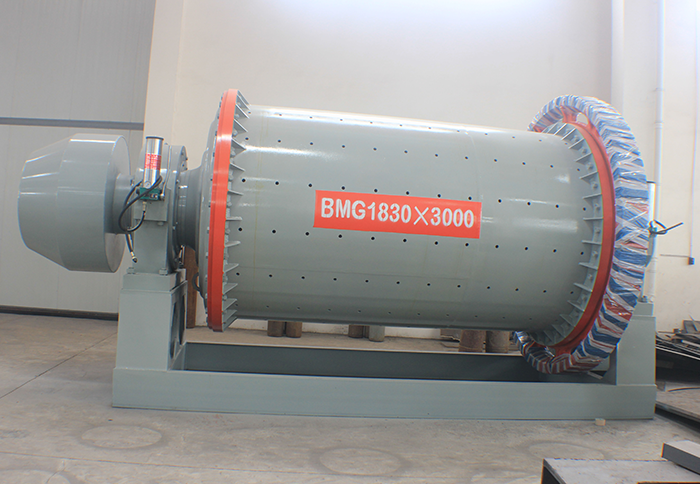

Ball Mill for sale

The ball mill is a crucial grinding device widely utilized across multiple industrial sectors, including cement, silicate products, novel construction materials, refractory materials, fertilizers, ferrous and non-ferrous metal ore dressing, as well as glass and ceramics manufacturing. Its fundamental operating principle lies in the utilization of grinding bodies within the mill cylinder (such as steel balls, rods, or other shaped media) that impact, compress, and grind the materials during rotational motion, effectively reducing them to the desired particle size.

Table of Contents

Advantages of ball mill

- High crushing efficiency: The ball mill uses the collision and friction between the grinding ball and the material to crush. It has high crushing efficiency and can obtain finer powder.

- Wide scope of application: Ball mill is suitable for crushing and grinding various materials, including metals, non-metals, ores, ceramics, etc.

- Simple operation: The operation of the ball mill is relatively simple. You only need to put the materials into the mill, add an appropriate amount of grinding balls and water or other media, and then start the equipment.

- Large output: The ball mill can produce continuously and has a large output, which can meet the needs of large-scale industrial production.

- Simple structure and easy maintenance: The ball mill has a relatively simple structure and is easy to maintain . At the same time, its sturdy and durable design also ensures its service life.

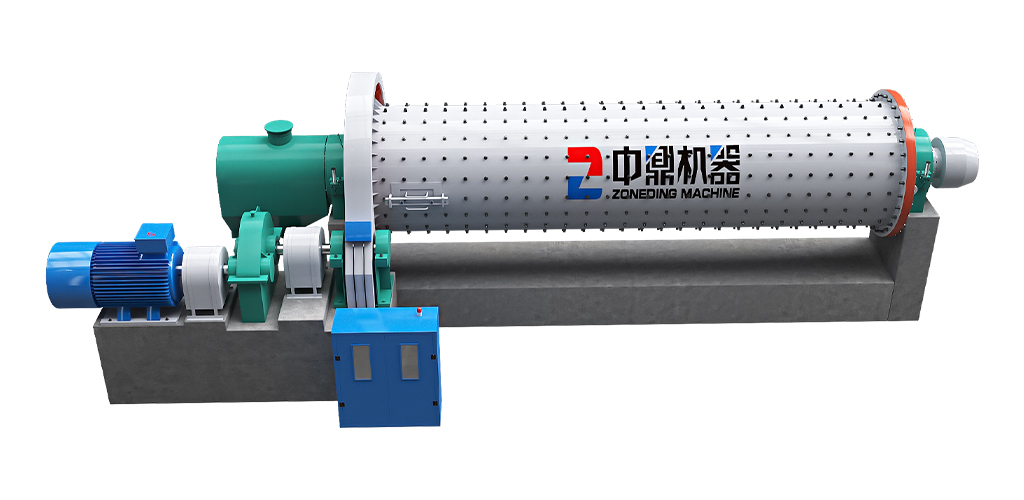

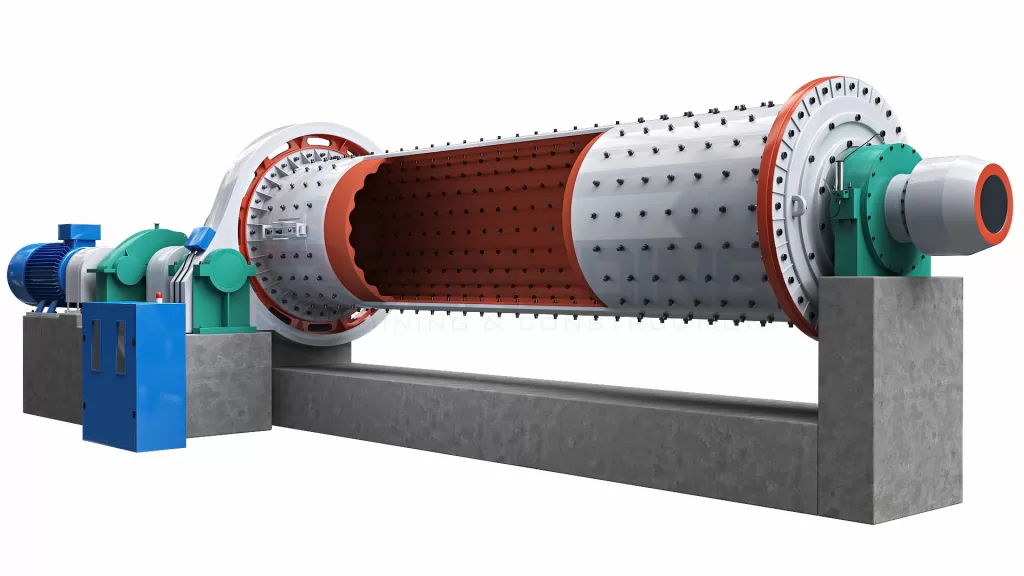

The structure and working principle of ball mill

The structure of ball mill mainly consists of cylinder, end caps, bearings, big gear, feeding device, discharging device, and grinding media (such as steel balls or ceramic balls) inside.

Its working principle is that the material enters the cylinder through the feeding device, and the cylinder rotates driven by the transmission device. The grinding media inside the cylinder subject the material to intense impact and friction due to centrifugal force and friction, crushing and grinding the material. After a certain period of time, the material grinded to the desired particle size is discharged through the discharging device.

What are the types of ball mills

- Based on different grinding methods, ball mills can be classified into dry and wet types. Dry ball mills are mainly suitable for grinding dry materials, while wet ball mills are suitable for grinding materials that require water or other liquids.

- According to the shape of the cylinder, ball mills can be divided into short cylinder type, long cylinder type, and tube mill, etc. Short cylinder ball mills are mainly used for rough grinding, while long cylinder ball mills are suitable for fine grinding and ultra-fine grinding.

- Based on different grinding media, ball mills can be classified into steel ball mill, gravel mill, and rod mill, etc. Steel ball mills use steel balls as grinding media, gravel mills use gravel or pebbles as grinding media, and rod mills use steel rods as grinding media.

mobile ball mill

The mobile ball mill has the characteristics of convenient transportation and usage in different sites. Compared with the traditional fixed-position ball mill, it is more flexible in use. It is suitable for operations such as ore grinding and building material processing in different sites, which can improve production efficiency and reduce material transportation costs and time.

Hot selling ball mill models

If you are interested in ball mill, please feel free to contact us! We will provide you with more than two solutions for you to choose from.

Parameters of ball mill

| Model | Rotate speed (r/min) | Grinding media Weight (T) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (KW) | Weight (T) |

| Φ900×1800 | 36 | 1.5 | ≦20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.5 |

| Φ900×3000 | 38 | 2.7 | ≦20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.7 |

| Φ1200×2400 | 36 | 3 | ≦25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200×3000 | 36 | 3.5 | ≦25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200×4500 | 36 | 5 | ≦25 | 0.074-0.4 | 11.6-5.8 | 55 | 13.8 |

| Φ1500×3000 | 32.4 | 7.5 | ≦25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500×4500 | 29.7 | 11 | ≦25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500×5700 | 27 | 12 | ≦25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830×3000 | 25.4 | 11 | ≦25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830×4500 | 25.4 | 15 | ≦25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830×7000 | 24.1 | 23 | ≦25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100×3000 | 23.7 | 15 | ≦25 | 0.074-0.4 | 6.5-36 | 155 | 34.8 |

| Φ2100×4500 | 23.7 | 24 | ≦25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2100×7000 | 23.7 | 26 | ≦25 | 0.074-0.4 | 8-48 | 280 | 56.6 |

| Φ2200×4500 | 21.5 | 27 | ≦25 | 0.074-0.4 | 9-45 | 280 | 51.8 |

| Φ2200×6500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200×7000 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200×7500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400×3000 | 21 | 23 | ≦25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400×4500 | 21 | 30 | ≦25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700×4000 | 20.7 | 40 | ≦25 | 0.074-0.4 | 12-80 | 380 | 94 |

| Φ2700×4500 | 20.7 | 48 | ≦25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200×4500 | 18 | 65 | ≦25 | 0.074-0.4 | 25-120 | 630 | 137 |

| Φ3600×4500 | 17 | 90 | ≦25 | 0.074-0.4 | 25-140 | 850 | 158 |

| Φ3600×6000 | 17 | 110 | ≦25 | 0.074-0.4 | 25-160 | 1250 | 175 |

| Φ3600×8500 | 18 | 131 | ≦25 | 0.074-0.4 | 45.8-256 | 1800 | 252 |

| Φ4000×5000 | 16.9 | 121 | ≦25 | 0.074-0.4 | 45-208 | 1500 | 203 |

| Φ4000×6000 | 16.9 | 146 | ≦25 | 0.074-0.4 | 65-248 | 1600 | 218 |

| Φ4000×6700 | 16.9 | 149 | ≦25 | 0.074-0.4 | 45-252 | 1800 | 238 |

| Φ4500×6400 | 15.6 | 172 | ≦25 | 0.074-0.4 | 54-306 | 2000 | 280 |

Ball mill customer work site

Related Products

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine