300 T/H Molybdenum Ore Beneficiation Line In South Africa

- Processing material: copper and molybdenum ore

- Processing capacity: 300t/h

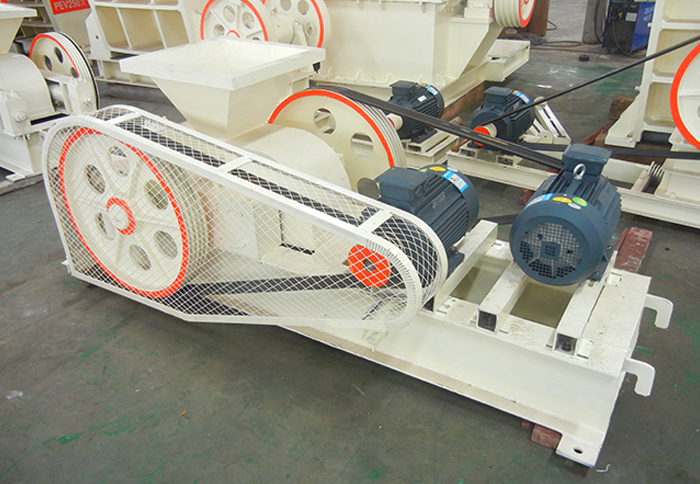

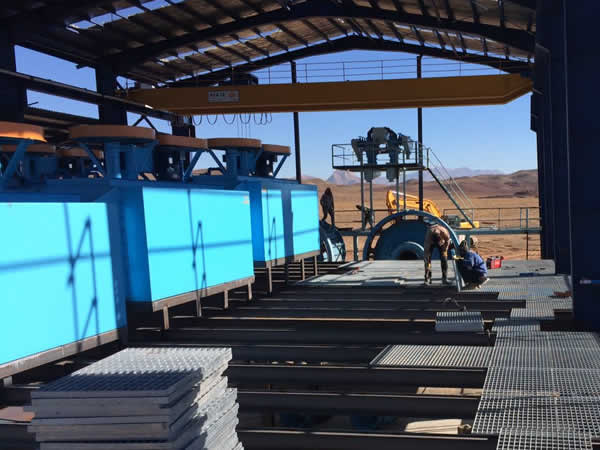

- Equipment configuration: PE jaw crusher, PEX impact crusher, ball mill, spiral classifier, flotation machine, dryer, feeder, conveyor, etc.

According to the natural conditions, terrain conditions and the characteristics of copper and molybdenum ore in the customer’s area, our experts configured the main equipment for the processing plant, including PE jaw crusher, PEX impact crusher, ball mill, spiral classifier, flotation machine, dryer and so on.

Project Introduction

Molybdenum is a metal element that was discovered relatively late, and was only extracted from molybdenum pyroxene by a Swedish chemist in 1792. Since molybdenum metal has the advantages of high strength, high melting point, corrosion resistance, wear-resistant research and so on, it has been widely utilized in industry.

Process Flow

The general flow is as follows:

1、Stage Crushing: The raw copper and molybdenum ore is fed into PE jaw crusher through vibrating feeder for primary crushing, and then into PEX jaw crusher for secondary crushing, and then into the circular vibrating screen for screening, large particles that do not meet the requirements are re-sent to the crusher for further crushing, and the materials that meet the requirements are fed into the storage silo through the conveyor.

2, grinding and classification: the copper and molybdenum ore in the storage bin enters into the ball mill through the conveyor for grinding and processing, and after grinding, it enters into the spiral classifier for classification and washing.

3、Flotation separation: The qualified copper and molybdenum ore enters into the mixing drum, and adds reasonable chemicals, mixes well, and then enters into the flotation machine for flotation separation.

4、Drying and dewatering: The concentrate obtained from flotation has more water, so it needs to enter the thickener for preliminary concentration and precipitation, and then enter the dryer for drying and dewatering, and then the dried concentrate can be obtained.

Customer’s Feedback

The production line designed by ZONEDING for our company has obtained high indexes of ore dressing, the concentrate grade has been increased by more than 50%, the cost of ore dressing has been greatly reduced, and the price of the whole production line is not too expensive, so the economic benefits obtained are very considerable.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

loading…

已经是到最后一篇内容了!

Related Cases

250 t/h Granite Crushing Production Line in Zambia

Client IntroductionProcess FlowProcess AdvantagesRelated ProductsRelated Cases The processing plant is a good engaged in the construction of special stone processing, production and sales of stone factory, the main products are gran…

Kazakhstan 150 t/h Copper Ore Crushing Production Project

Project DescriptionEquipment ConfigurationCustomer FeedbackRelated ProductsRelated Cases The company examined the crushing equipment in China for nearly half a year, but was still attracted by the powerful processing capacity and …

Pakistan 300t/h River Pebble Sand Making Production Line

Introduction of river pebble sand mechanismClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer mainly provides stone and mechanism sand for mixing station, the production line is set up close to the river, an…

Oman 100t/h Complete Limestone Crushing Production Line

Limestone introductionClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer learned that 2 years ago a friend from the company purchased a stone crushing line, the model is small, but the operation is very st…

Malaysia 250 t/h basalt crushing line

Basalt introductionClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer is a mining boss in a certain place, already has an iron ore production line, which is a large basalt crushing production line, introduce…

South Africa 300t/h iron ore crushing line

Introduction of Iron OreClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer enterprise is a well-known local mining group to participate in the investment and construction of iron ore production line, the com…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine