250 T/H Panama Lead-Zinc Ore Flotation Machine Production Line

- Processing material: lead-zinc ore

- Processing capacity: 250t/h

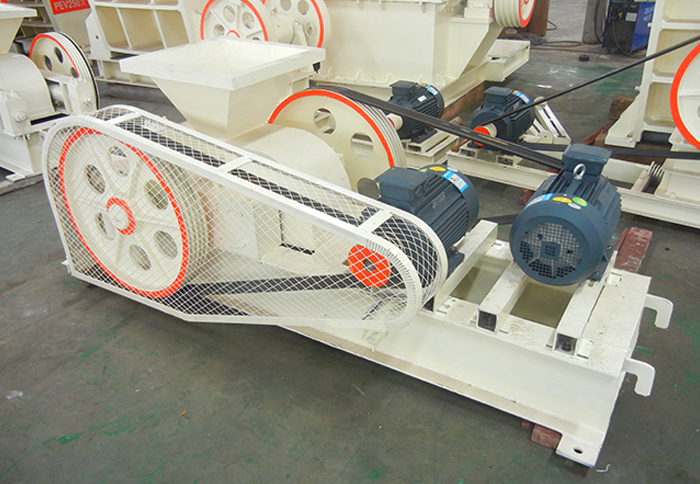

- Equipment Configuration: Jaw Crusher, Impact Crusher, Ball Mill, Flotation Machine, Dryer, Spiral Classifier, Mixing Barrel, Thickener, etc.

The terrain of this customer’s area is relatively complex and diverse, Zoneding machine experts carried out an in-depth inspection of the processing site and studied the mineralogical characteristics of lead-zinc ore, optimized and upgraded the traditional beneficiation process, and then designed a lead-zinc ore beneficiation production line with an output capacity of 250 t/h

Introduction of Lead-Zinc Ore

Lead-zinc ore is a very versatile ore with high application value in many fields such as electric, machinery, metallurgy, chemical industry, light industry, military, medicine and so on. Lead-zinc ore reserves in the world are relatively large countries such as Canada, India, China, Argentina, Mexico, Brazil, etc., generally using flotation process for its purification and processing.

Project Introduction

The customer is located in the area of complex and diverse terrain, Zoneding machine experts carried out an in-depth investigation of the processing site, and the mineralogical characteristics of lead-zinc ore, the traditional beneficiation process optimization and upgrading, and then designed a production line of lead-zinc ore beneficiation production with an output of 250/h, the main equipment has PE600 × 900 jaw crusher, PF1520 impact crusher, Ф 4000×6700 ball mill, SF type flotation machine, etc., roughly after crushing, grinding, classification, flotation, drying and other five processes, to obtain the concentrate recovery rate of more than 60%, and all the beneficiation indexes are in line with the ideal requirements.

Advantages of production line

1、Good energy-saving effect: the energy-saving effect of the core equipment of the whole production line, the flotation machine, reaches more than 70%, which can effectively realize the recycling and reuse of water resources, greatly saving the cost of water, and greatly reducing the amount of energy consumption.

2, high degree of automation: the design of advanced electronic control manipulation device makes the whole production line’s degree of automation increased by more than 2 times, which reduces the labor cost and management cost.

3、High beneficiation efficiency: the operation process is quite stable, low failure rate, beneficiation efficiency increased by more than 30%.

4、Low carbon and environmental protection: the design of sealing device and dustproof device greatly reduces the amount of dust and noise of the whole production line, low carbon and environmental protection effect is better.

Feedback

The reasonable layout of the entire production line, high efficiency mode of operation, green production state are very satisfied with my company, for my company to save a lot of investment costs, I hope to have the opportunity to cooperate again.

Related Products

Jaw Crusher

Jaw CrusherCoarse CrushingJaw Crusher for SalePurpose of Jaw CrusherAll Kinds of Jaw CrusherWorking Principle of Jaw CrusherThe Advantages of Jaw CrusherParameters of Jaw CrusherCustomer SiteFAQRelated ProductsJaw crusher is mainly used for mediu…

Impact Crusher

Impact CrusherWhat is Impact Crusher?Applications of Impact CrusherImpact Crusher Working PrincipleStructural Advantages of ZDM Impact CrusherGeneral SpecificationImpact crusherStone crushing plant processCustomer siteFAQRelated ProductsImpact cr…

Sand Making Machine

Sand Making MachineFine CrushingWhat is a sand making machine?Applications of sand making machineProduction Process Of Sand Processing PlantTypes of sand making machine1. VSI series sand making machine2.PCL series sand making machine3. Mobile san…

Cone Crusher

Cone CrusherCone Crusher For SaleCone Crusher TypesApplication of Cone CrusherCone Crusher CharacteristicsWorkflow of stone crushing plantHot sale cone crusher and screening solutionMobile Cone Crushing PlantProducing Line Of Mobile Cone Crushing…

Hammer Crusher

Hammer CrusherWhat is a Hammer mill crusher?What are the types of hammer crushersWhat is the structure of a hammer crusherThe working principle of the hammer millParameterPC Hammer CrusherPCZ Heavy Hammer CrusherCustomer SiteFAQRelated Products …

Roll Crusher

Roll CrusherWhat is Roll Crusher Machine?Roller Crusher ClassificationThe Roller Crusher Key Applications IncludeRoll Crusher Several Structural Advantages That ContributeWorking Principle of Roller Crusher MachineGeneral SpecificationRoll Crushe…

Compound Crusher

What is Compound Crusher?Compound Crusher AdvantagesCompound Crusher ApplicationThe Working Principle of Compound CrusherGeneral SpecificationCompound CrusherFAQRelated Products Compound Crusher Compound crusher is the newly developed equipment …

Fine Crusher

Applications of ZDM Fine CrusherThe Fine Crusher AdvantagesStructure of the Fine CrusherWorking Principle of Fine CrusherGeneral SpecificationFine crusherFAQRelated Products Fine Crusher Fine crusher is also called tertiary crusher, which adopts…

loading…

已经是到最后一篇内容了!

Related Cases

250 t/h Granite Crushing Production Line in Zambia

Client IntroductionProcess FlowProcess AdvantagesRelated ProductsRelated Cases The processing plant is a good engaged in the construction of special stone processing, production and sales of stone factory, the main products are gran…

Kazakhstan 150 t/h Copper Ore Crushing Production Project

Project DescriptionEquipment ConfigurationCustomer FeedbackRelated ProductsRelated Cases The company examined the crushing equipment in China for nearly half a year, but was still attracted by the powerful processing capacity and …

Pakistan 300t/h River Pebble Sand Making Production Line

Introduction of river pebble sand mechanismClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer mainly provides stone and mechanism sand for mixing station, the production line is set up close to the river, an…

Oman 100t/h Complete Limestone Crushing Production Line

Limestone introductionClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer learned that 2 years ago a friend from the company purchased a stone crushing line, the model is small, but the operation is very st…

Malaysia 250 t/h basalt crushing line

Basalt introductionClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer is a mining boss in a certain place, already has an iron ore production line, which is a large basalt crushing production line, introduce…

South Africa 300t/h iron ore crushing line

Introduction of Iron OreClient’s situationCustomer FeedbackRelated ProductsRelated Cases The customer enterprise is a well-known local mining group to participate in the investment and construction of iron ore production line, the com…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine