Gold ore ball mills are commonly used for the crushing and grinding of gold ores before the extraction and beneficiation process. When selecting a gold ore ball mill, factors such as the properties of the gold ore, the model specifications, the liner material, and the steel ball composition need to be considered.

Gold Ore Properties:

There are various types of gold-bearing minerals, including natural gold, silver-bearing gold minerals, gold-platinum group element minerals, bismuth gold ore, gold-tellurium minerals, and gold-antimony ore. Gold ore is often fine-grained and may have rough surfaces due to being embedded in other mineral grains.

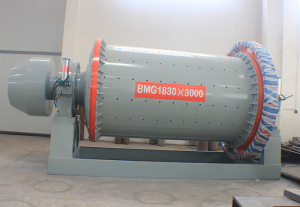

Gold Ore Ball Mill Models:

Gold ore ball mill models have complete specifications and are suitable for different sizes of gold processing plants. The cylinder diameter of gold ore ball mills ranges from 0.6m to 4.5m, with production capacities ranging from 0.65t/h to 615t/h. Small gold ball mills, with cylinder diameters below 2.1m, have capacities below 6t/h. Some common models for small gold ball mills include φ2100mm×4500mm, φ2100mm×4000mm, φ2100mm×3600mm, and so on. Large gold ball mills, with cylinder diameters larger than 2 meters, are suitable for large-scale gold processing plants and have higher processing capacities.

Gold Ball Mill Liners:

The lining plate is a key component of a ball mill that protects the cylinder and enhances the load. Proper selection of gold ball mill liner material is crucial. Currently, three categories of liners are commonly used: metal liners, rubber liners, and magnetic liners. Among them, high manganese steel liners are commonly used for wet ball mills and have a service life of about 8 months. Rubber liners have a service life approximately three times longer than high manganese steel liners. Magnetic liners have an even longer service life, but their use is less common. Based on customer demands, rubber or magnetic liners can also be assembled in gold ball mills.

Steel Balls for Gold Ball Mills:

Steel balls are important grinding media in ball mills and impact the liners. The filling rate of steel balls in the mill affects the wear and tear on the liners and the grinding efficiency. The media ratio refers to the proportion of different sizes of steel balls. The larger the steel ball, the greater the impact on the liners. Thus, the impact force needs to be controlled to avoid liner fractures. The filling rate of small and medium-sized ball mills is generally between 35-45%, while large ball mills are filled at around 30-35%. The appropriate steel ball ratio can be calculated based on the liner thickness, ball diameter, ore hardness, and feed size.

Gold Ore Ball Mill Price:

The price of gold ball mills and the model specifications are directly related. Larger models have higher prices. For small ball mills with a diameter below 2 meters, the price ranges from tens of thousands to hundreds of thousands of dollars. For larger ball mills such as the 2736 model, the price can reach around 1 million dollars. To save costs, it is advisable to conduct grinding tests and choose smaller ball mill specifications that meet output requirements to avoid resource wastage and reduce investment costs in the plant.

Zoneding Machine

Zoneding Machine