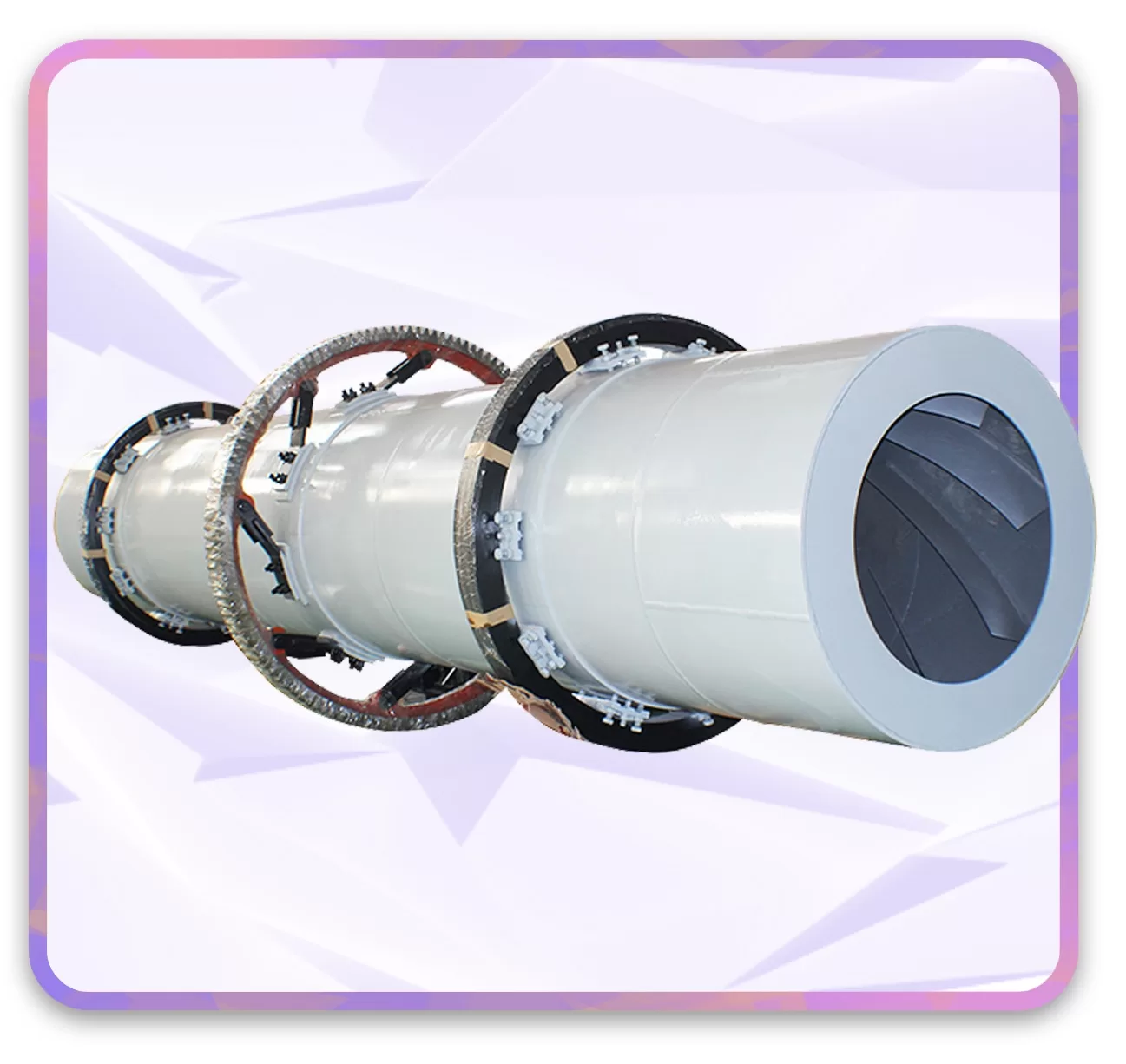

Ore Powder Dryer

The ore dryer is versatile, suitable for drying a range of materials including slag, limestone, clay, and ores. It’s customizable for various industries like cement, mining, and metallurgy, tailored to specific material types and user requirements.

- Capacity: 300-3000 t/d

- Dried Moisture(%): 12-15% (Adjustable)

- Heat Source: biomass, natural gas, diesel, coal, etc.

- Application: Widely used in cement, mining, building materials, chemicals, metallurgy, slag, clay and other industries.

What is Ore Powder Dryer?

Zoneding Machinery is a specialist in the production of various ore powder dryers, including manganese ore powder dryer, nickel ore powder dryer, as well as for drying powder or particle of cobalt, tin, chromium, gold and mercury, etc. This drying equipment is indispensable in the rare metal ore dressing operation. Zoneding fine ore powder dryer is a new type adopting indirect hot-blast stove technology (electricity as the heat source also available), in case that the fine ore powder is blended in sulphide and its hazardous materials.

Applications of Ore Powder Dryer Machine

Ore powder dryer or mineral powder dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, which is mainly used for drying wet and heavy materials such as mineral powder, slag, limestone, clay, sand, quartz sand, grain slag, etc. Zoneding ore powder dryer can also be used for drying metal powder, so it can be called metal powder dryer.

Examples of Ore Powder Applications

Advantages of Zoneding Ore Powder Drying Machine

- Advanced technology of high-temperature and rapid drying adopted, which is of great efficiency;

- Specially designed for drying ore powder with variable rotating blade angle and adjustable rotor speed.

- Equipped with a special scraper device to avoid the sticking of wet ore powder

- A wet material reflux layer is arranged on the upper part of the dryer, and the dryer is equipped with special stirrer.

- High-speed stirring and air drying are combined to fully decentralize the viscous powder and improve the contact area between the materials and the heat medium, which are conducive to drying process.

Working Principle of Ore Powder Dryer

Ore powder drying machine adopts high-temperature and rapid drying technology, which is a successful combination of hot-air slot rotary-plate drying machine and air-flow dryer. Wet powder is thrown up and impacted into pieces by the high-speed rolling blades. Meanwhile, well decentralized powder gets adequate and effective contact with the scorching wind. Thus, the heat transformation is realized. In addition, there is cleaning device on the inner wall of the dryer to clean the lumpy material and those are stuck on the inner wall, which can expeditiously avoid blocking.

Working Principle of Ore Powder Dryer

How to Maintain Ore Powder Dryer

Due to the working environment and often process corrosive materials, ore powder dryer needs good antiseptic protection. Two frequently used methods to protect the drying machine from corrosion.

1. Electrostatic coating. It is a means of spraying a new type powder on the cylinder, which is safer and causes less environmental pollution. This new powder is of the same anticorrosion as stainless steel. Besides, this powder is excellently resisted from outdoor weather and heat. Therefore, stainless steel can be replaced with plain carbon steel in dryer production, which has lower cost.

2. Deactivation and phosphorization. These two methods are grouped as a one-time process through electrical and electrochemical reactions. The stained steel layer can be recovered to its original color. A dense anti-rust layer is formed by phosphorization at the same time. Easy operation and cost savings make this method the most welcome and commonly used one.

General Specification

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

FAQ

Q1. Who are we?

A1: Zoneding Machine is manufacture of mining machine which is located in Henan province of China. We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004.

Q2. What is our main crusher products?

A2: Jaw Crusher/Cone Crusher/Vibrating Screen/Sand Making Machine/Mobile Stone Crusher Plant/Vibrating Feeder/Fine Sand Recovery Machine/Screw Sand Washing Machine/Impact Crusher/Vertical Shaft Impact Crusher/Hammer Crusher/Belt Conveyor/Stone Crushing Plant.

Q3. What about the price ?

A3: We are able to give you competitive price than market one cuz we are factory, and we have a policy that ” for saving time and absolutely honest” business attitude,we quote as low as possible for any customer, and discount can be given according to quantity

Q4. What services can we provide?

A4: Accepted Delivery Terms: FOB, CFR, CIF;

Accepted Payment Currency: USD,EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken: English,Chinese,Spanish,Arabic,French,Russian

Q5: When will the delivery be?

A5: For inventory goods, we can ship them within 3-5 days. For customized equipment and other devices, we will specify according to clients’ needs as we quote.

Related Products

Drum Dryer

What is Drum Dryer?Applications of Single Drum DryerStructure and Advantageous Functions of the Drum DryerDifference Between Single Drum Dryer and Three Drum DryerAttention Needed When Operating a Single Cylinder DryerGeneral SpecificationCustomer…

Sludge Dryer

What is Sludge Dryer?Applications of Sludge Dryer MachineClassification and Differences of Sludge DryersGeneral SpecificationCustomer SiteFAQRelated Products Sludge Dryer Zoneding Company conducted technical research on sludge treatment, created…

Aggregate and sand dryers

What is Sand Dryer ?Application of Sand DryerWorking Principle of Sand Drying EquipmentStructure And Advantages of Rotary Dry Sand MachinePrecautions for Installation In The Sand DryerGeneral SpecificationSand dryerFAQRelated Products Sand Dryer …

Three-drum Dryer

What is Three-Drum Dryer?Applications of Three-Drum DryerHow Three-Cylinder Dryer Works?The structural advantages of the zoned three-drum rotary dryerHow to Choose a Suitable Dryer?General SpecificationSand dryerFAQRelated Products Three-drum Drye…

Bentonite Dryer

What is Bentonite Dryer?Applications of Bentonite DryerHow Bentonite Dryer Works?Structural Advantages of Zoneding Bentonite DryerGeneral SpecificationFAQRelated Products Bentonite Dryer Bentonite, a versatile clay, varies in color with iron con…

Coal Dryer

What is Coal Dryer?Applications of Coal Dryer MachineWorking Principle of Coal Dryer MachineStructural Advantages of Coal Drying MachineEnvironmental Value of Coal DryerGeneral SpecificationFAQRelated Products Coal Dryer Zoneding’s coal dryer is…

Slurry Dryer

What is Slurry Dryer?Applications of Slurry DryerHow Does A Slurry Dryer WorkAdvantages of Slurry DryerPrecautions for The First Operation of The Slurry DryerGeneral SpecificationCustomer CaseFAQRelated Products Slurry Dryer The slurry-residue d…

Slag Dryer

Slag Dryer For SaleApplications of Slag Dryer Machine1. Blast furnace slag2.Furnace slag3.Coal gangue4.Bauxite residueThe Working Process of Slag Rotary Drying SystemStructural Advantages of Zoneding Slag DryerHow to Prolong Slag Drying Machine Se…

Sawdust Dryer

What is Sawdust Dryer?Applications of Sawdust Rotary DryerStructure and Benefits of the Sawdust DryerWorking Principle of Sawdust DryerHow to Improve the Efficiency of Zoneding Sawdust Dryer MachineGeneral SpecificationFAQRelated Products Sawdust …

Rotary Dryer

What is Rotary Dryer?The Application of Rotary DryerRotary Drum Drying StructureThe Classification of Rotary Drum DryerWorking Principle of Rotary DryerRotary DryersAdvantagesGeneral SpecificationDrying Machine Production ProcessCustomer SiteFAQRe…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine