Spiral Chute

Spiral chute, which is also known as spiral chute separator, is a kind of gravity separation equipment.

- Product Output:0.15-6t/h

- Feeding Size:0.3-0.02mm

- Applied material: iron ore, ilmenite ore, chromite ore, pyrite ore, zircon ore, rutile ore, monazite ore, tungsten ore, tin ore, tantalum ore, niobium ore and other materials with enough specific gravity difference

Information of Spiral Chute

Spiral gravity separator spiral chute is also called spiral concentrator or gravity separator, it’s a kind of gravity concentrator which can separate mineral particles according to density, granularity and shape by the interaction of centrifugal force, friction force of chute surface, water flow pressure and gravity of minerals. Spirals are made of high-density fiberglass, high quality emery and unsaturated resin.

The spiral chute is suitable for separation of 0.3-0.02mm fine materials such as iron ore, ilmenite ore, chromite ore, pyrite ore, zircon ore, rutile ore, monazite ore, tungsten ore, tin ore, tantalum ore, niobium ore and other materials with enough specific gravity difference. It is the best roughing gravity equipment, which has been widely used in ferrous and nonferrous metal mines.

Spiral Chute Application:

Spiral chute concentrator is widely used to the separation for mineral particles, the size of which ranges from 0.3 to 0.02 mm. it can be suitable for dealing with different kinds of ores, such as below:

-Rutile, ilmenite and zircon concentration.

– Iron ore, chromite and manganese beneficiation.

-Tin, tantalum and ore concentration.

-Gold, native copper and base metal recovery.

-Silica sands processing.

-Titano-magnetite concentration.

Spiral chute features:

1. Reasonable structure and small area occupation, Non-required power

2. High recovery, high efficiency, and precise separation

3. Light in weight, anti corrosion, rust and wear resistant

4. Simple installation and Minimal maintenance requirements

5. Low operating cost and long working life

Structure Features of Spiral Chute

The spiral chute parts have a distributor and feed chute in the upper part and a product interceptor and collection chute in the lower part. The entire equipment is framed vertically with steel frames.

Working Principle of Spiral Chute

Cuatomer Case

General Specification

spiral chute

| Model | Processing capacity(t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

FAQ

1.Are you a manufacturing or trading company?

We are manufacturer. Our factory established in 2004.

2.What is the after-service of your company?

We can provide the foundation drawing, installation service, training, spare parts and other service according to the customer’s requirements.

3. Which mineral processing method should I choose?

According to the properties of minerals, we will choose the treatment method that most suitable for you.

4. What machines are usually required for the whole production line?

Usually there are feeder, primary and secondary crushers, vibrating screen, ball mill, classifier, spiral chute, magnetic or flotation machine, dryer, etc. Equipment can be adjusted.

5. What is the final mineral concentration?

It depends on the ore grade. The final concentration of gold ore can reach 80-90%.

Related Products

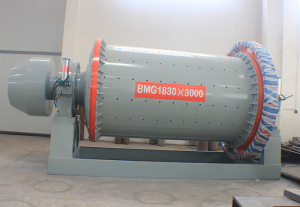

Ball Mill

Our ball mill are available in different styles and many models in each style to adapt to various grinding requirements.

Rod Mill

Rod MillRod Mill For SaleWorking Principle of Rod MillProduct Features of Rod MillRod Mill shipmentParameters of Rod MillRod millService Supportof Rod MillFAQRelated ProductsOur Rod Mill are available in different styles and numerous model sizes …

Ceramic Ball Mill

Ceramic Ball MillCeramic ball mill For SaleAdvantages of Ceramic ball millFunctional Advantages of Ceramic ball millApplication Scenarios of Ceramic ball millCeramic ball mill shipmentCeramic ball mill customer work siteParameters of Ceramic ball…

Flotation Machine

Flotation MachineFlotation Machine For SaleAdvantages of Flotation MachineFlotation Machine: Suitable Ore TypesStructure of flotation machinePrinciple of Flotation MachineFlotation ProcessParameters of Flotation Machineflotation machineAssembly s…

Spiral Classifier

Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

Mixer

Introduction of MixerThe Application and Function of Agitating TankThe Working Principle of Agitating TankAgitating Tank ManufacturerGeneral SpecificationMixerFAQRelated Products Mixer Mixing barrel is mainly used in all kinds of metal mining in…

Wet Drum Magnetic Separator

Wet Drum Magnetic SeparatorWhat is wet drum magnetic separatorFeatures of Wet Drum Magnetic Separator:Structure of Wet Drum Magnetic SeparatorPrinciple of Wet Drum Magnetic SeparatorCustomer Case of Wet Drum Magnetic SeparatorSpecification of Wet…

Shaking Table

Shaking Table For SaleAdvantages of Shaking TableApplication of Shaking TablePrinciple and structure of shaking tableI. Working PrincipleII. Structural compositionParameters of shaking tableShaking Tableshaking table customer work siteFAQRelated P…

Gold Mine Wet Pan Mill

Wet Pan Mill for saleApplicationsWet Pan Mill AdvantagesProduct StructureWet Pan Mill Working PrincipleParameters of Wet Pan MillRelated Products Gold Mine Wet Pan Mill is a highly efficient, energy-saving and easy-to-ope…

Jigging Separator Machine

Jigging Machine for saleApplicationsProduct StructureWorking PrincipleParameters of Jigging MachineJigging Machine customer work siteRelated Products Jigging Machine(jig concentrator, jig machine, mineral jig, Jiggin…

loading…

已经是到最后一篇内容了!

Zoneding Machine

Zoneding Machine